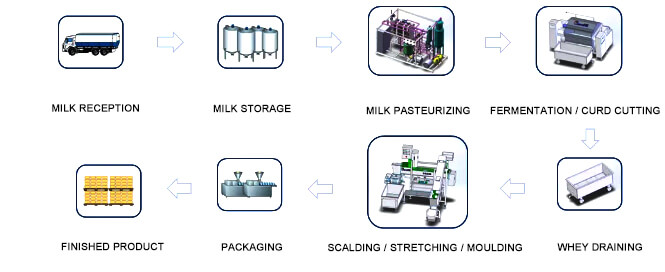

The cheese processing line industry chain is basically complete. Independent localization can be realized from milk collection, milk storage, sterilization, fermentation and finished products. The following equipment are mainly introduced: the first is cheese tank, the second is pre press, the third is press, and the fourth is blanching and stretching unit.

Cheese trough can be divided into U-shape, O-shape and double O-shape in terms of shape. This is the technical table of cheese trough of our company. The so-called cheese tank is mainly used to ferment, coagulate and complete whey in the cheese tank after sterilization of cow and sheep milk. This is its structure diagram. Below is the tank body and above is the cutting and mixing device. This is the working state of the cheese trough. U-shaped reversible cheese tank, the biggest difference is that it can be overturned, which is characterized by no residue during pouring. This is an O-shaped reversible cheese tank.

The second equipment is the pre press. The main purpose is to pre press the curd of cheese and discharge whey. First, the first feature is the use of man-machine interface setting, which can set the preloading times and preloading time in advance through the man-machine interface to achieve the desired effect. The second is equipped with CIP cleaning. This is the structure diagram of the pre press. Below is the cheese bed and above is the pre press device. There are roughly two types: one is that the preloading device does not move, and the other is that the preloading device is integrated with the pusher.

The third equipment is the press, which is mainly used to put the cheese in the mold and finally discharge whey. One feature is mold matching. Then, the pressing time and pressure can be set through the man-machine interface. There are two kinds of press in structure, one is longitudinal and the other is transverse. The driving part of longitudinal press includes cylinder drive, electric cylinder drive and hydraulic cylinder drive. This is a transversely driven press.

The last one is blanching and stretching machine. The main function is to crush, blanch and stretch the fermented cheese. Its main features: first, it can form a whole production line with other equipment, and can also be used alone. Second, the mold can be customized. You can see why the equipment is dirty because the outer surface is sandblasted and the inner surface is Teflon coated. Even if the stainless steel surface is electropolished, there will still be adhesion of cheese products, so we specially treated it with Teflon. This is the structure diagram of the blanching and stretching machine. It is transported from the lower part to the upper part for rotary crushing, and blanching, stretching and forming are carried out in the tank.