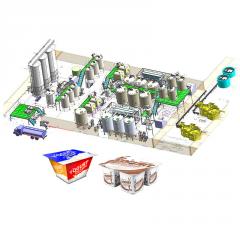

Cheese Processing Line is a comprehensive facility system used to convert raw milk into cheese. It covers a series of complex processes from raw material reception, pretreatment, fermentation, solidification, cutting, milk discharge, shaping, pressing, salinization, ripening to packaging.

Here is a brief explanation of the main process of cheese processing:

Raw material reception and pre-treatment: The raw milk is first inspected upon receipt to ensure that the quality meets the standards Preheating, standardization (adjusting the ratio of fat and protein), filtration, and pasteurization are carried out to kill harmful microorganisms and retain beneficial bacterial strains.

Fermentation: • Add specific lactic acid bacteria or mold starter to the pasteurized lotion to start the fermentation process. This step converts lactose into lactic acid, lowers pH, and creates conditions for cheese solidification.

Coagulation: When the lactate content reaches a certain level, the addition of rennet promotes the coagulation of milk protein to form clots, while whey is separated.

Cutting and milk discharge: • Use cutting equipment to cut solidified milk into small particles, increase surface area, and facilitate further discharge of whey Separate whey from curd particles by gentle stirring or gravity.

Forming: Pour the discharged curd particles into the mold, and the shape and size of the mold vary depending on the type of cheese needed.

Pressing: • Remove remaining whey through mechanical pressure while helping cheese shape and increasing density Salinization: • Salinization can be carried out by spreading dry salt, soaking in salt water or spray to enhance flavor, inhibit the growth of undesirable microorganisms and promote the formation of skin.

Maturation: • Maturation is a key step in cheese production, usually carried out under specific temperature and humidity conditions, with a duration ranging from a few weeks to several years. During this process, the flavor, texture, and aroma of cheese will gradually develop and mature.

Packaging: Mature cheese is cut and weighed according to market demand, and packaged using methods such as vacuum packaging and modified atmosphere packaging to extend its shelf life and maintain quality.

The entire cheese processing production line is usually highly automated, including CIP (in place cleaning) systems to ensure food safety and hygiene of the production line, as well as advanced monitoring systems to control and optimize the parameters of each production process. In addition, different types of cheese (such as soft cheese, hard cheese, blue cheese, etc.) will have their specific processing details and process requirements.

The technical points of cheese processing production lines mainly focus on the following aspects, and the application of these technologies can significantly improve production efficiency, product quality, and safety:

Automation and Intelligence: Highly automated production lines, including raw material receiving, metering, mixing, processing, packaging, and other processes, reduce manual intervention, improve production efficiency and consistency Intelligent control systems, such as PLC (Programmable Logic Controller) and SCADA (Data Acquisition and Monitoring Control System), achieve precise control and real-time monitoring of the entire production process.

Efficient and energy-saving technology: • Adopting energy-saving heating and cooling systems, such as heat exchangers and waste heat recycling technology, to reduce energy consumption The application of flash distillation or low-temperature long-term technology in the pasteurization and heat treatment process can effectively kill bacteria while maintaining the nutrition and flavor of dairy products Membrane filtration technology: Ultrafiltration (UF) and microfiltration (MF) technologies are used in the pre-treatment stage of dairy products, which can effectively remove bacteria and impurities, concentrate proteins, and improve the quality and stability of the final product

Biotechnology: • Using specific bacterial strains for precise fermentation, improving fermentation strains through genetic engineering to achieve better flavor, faster maturation speed, and higher yield Precision temperature control technology: The use of precise temperature control systems in key steps such as fermentation and maturation ensures temperature stability at each stage, which is crucial for maintaining microbial activity and controlling chemical reaction rates.

Sterile packaging technology: • Adopting sterile filling and sealing technology to ensure that products are not contaminated by microorganisms during the packaging process and extend shelf life Data driven management and optimization: • Utilize big data analysis and machine learning algorithms to analyze production data, predict maintenance needs, optimize production plans, and improve overall operational efficiency Food safety and hygiene design: • Equipment design follows hygiene principles, such as easy to clean structures, use of food grade materials, and CIP systems, to ensure high standards of hygiene in the production environment

Environmental Protection and Sustainability: • Wastewater treatment and waste recycling technologies to reduce the impact of production on the environment. For example, whey recycling can be reused in other food or feed production.

In summary, the cheese processing production line integrates multiple advanced technologies, aiming to achieve an efficient, safe, and environmentally friendly production mode while meeting the market's demand for high-quality cheese products.

Advantages:

1.Opportunity to realize products with customized recipes.

2.Opportunity to produce more than one product with the same processing line.

3.High quality of the final product keeping an elevated nutritional value.

4.Wide customization of the final product.

5.Maximum yield, minimum production waste.

6.Highest energy savings thanks to the most advanced technologies.

7.Complete line supervision system through monitoring of every process phase.

8.Recording, visualization and printing of all daily production data.

Cheese Production Line

Scalding Equipment

Screw Elevating Equipment

Forming Mould

Brining Tunnel

Scalding, Stretching and Moulding Unit

Round Shape Tilting Cheese Vat

U-shape Cheese Vat

Whey Draining

Full-auto Cheese Vat

Direction for use

Cutting\cooking\stretching\moulding system

Automatic control, cutting curd\cooking\stretching\moulding,

Capacity: 150-250kg/h,

Include : cutting curd\cooking\stretching\moulding,

speed adjustable, hot water generating and recirculation system, include valves, filter, pump and piping for water rout

Description of application effect

1. construction material: SUS304;

2. Turning type, easy for pour out cheese;

3. With cutting knives, made of acid-resistant steel.

4. Mechanical agitator, of sanitary construction,

5. Automatic drain whey, automatic turning over.

6. With a system of heating curd with hot water,

7. With a system spreading of process water onto the entire surface.

8. Dynamic temperature adjustment and measurement.

9.CIP cleaning/disinfection, automatic control

1. Material: SUS304;

2. Three layers of Pu insulation, dimple cushion sheath heating and cooling;

3. Oval shape,

4. Two mixers, one for stirring and the other for cutting the cheese into small pieces;

5. The agitator can move from one end to the other;

6. Automatic temperature control panel;

7. Automatically discharge whey outlet, etc.

8. Power: 380V, 50Hz, three-phase; If other requirements can be customized.

Size Chart of This Design

Ingredients and products for Cheese Processing Line

The main raw materials for Cheese Processing Line include milk, cheese culture, rennet, salt, etc. These raw materials are processed through specific techniques to ultimately produce various types of cheese products.

The production process of Cheese Processing Line involves multiple steps, including heating, cooling, solidification, shaping, fermentation, etc. These steps work together to transform raw milk into cheese products with specific flavors and textures. In this process, the types and flavors of cheese can be achieved by adjusting the proportion of raw materials and processing conditions to meet the needs of different consumers.

The final product can be various types such as soft cheese, semi hard cheese, hard cheese, etc. These cheeses have their own characteristics in terms of nutritional value and taste, and are widely used in various fields such as food processing, catering services, and household consumption. In addition, some special types of cheese, such as cheese flavored with vanilla, spices, or smoke, as well as red Leicester cheese with specific colors, are achieved by adding corresponding additives during the production process.

The production of Cheese Processing Line is not limited to traditional cheese making, but also includes the customization advantage of the production line, which enables producers to flexibly adjust production formulas according to market demand and produce diversified cheese products. This flexibility is not only reflected in the ability to produce a variety of different types of cheese, but also includes the ability to produce other dairy products besides cheese, such as cheese powder, which is a food ingredient made by crushing natural cheese through a crushing process. It has delicate particles and rich flavor, and is widely used. It can be used for flushing, adding milk, making cakes, mixing noodles, etc.

Customized solution for Cheese Processing Line

The customized solution for Cheese Processing Line mainly involves customizing the various components of the cheese production line according to specific needs to ensure that the quality, yield, and nutritional value of the final product meet expected standards. Customized solutions typically include the following key aspects:

Equipment selection and configuration: Select suitable cheese making equipment based on production needs, including but not limited to cheese forming machines, cheese slicing machines, packaging machines, etc. The selection of these devices will directly affect production efficiency and product quality.

Production process design: Design the optimal production process based on the type of cheese and expected output. This includes key steps such as raw material pretreatment, fermentation, and maturation to ensure that each step meets the specific requirements of the product.

Quality control: Implement strict quality control measures, including raw material inspection, monitoring during the production process, and quality testing of finished products, to ensure consistency and safety of product quality.

Nutrition and hygiene standards: Ensure that production lines comply with national and international nutrition and hygiene standards, including the use of safe materials and the design of easy to clean equipment to reduce the risk of cross contamination.

Customized service: Provide customized services, such as adjusting the taste, appearance, etc. of cheese according to customer needs, to meet the preferences of specific markets or consumers.

Technical support and training: Provide necessary technical support and operational training to ensure that operators can use equipment correctly, operate production lines efficiently, and ensure product quality and safety.

After sales service: Provide regular maintenance and upkeep services to ensure the long-term stable operation of equipment, reduce failure rates, and improve production efficiency.

Through the above customized plan, it can be ensured that the produced cheese not only meets quality standards, but also meets specific market demands, thereby enhancing the competitiveness and market share of the product. In addition, by optimizing the production process and equipment configuration, cost savings and efficient utilization of resources can also be achieved.