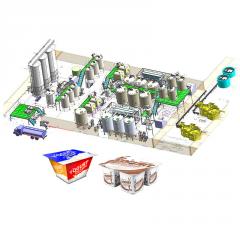

Pasteurized milk production line is a processing process used to process raw milk, which is heated to a sufficiently high temperature and maintained for a certain period of time to kill most harmful microorganisms while maintaining the original nutritional content and taste of the milk as much as possible. This treatment ensures the safety of milk and extends its shelf life.

A standard pasteurized milk production line typically includes the following key steps:

1. Reception and storage: Firstly, freshly collected milk will be transported to the processing plant and stored in refrigerated tanks to maintain a low temperature and prevent bacterial proliferation.

2. Pre processing: Milk needs to be filtered and cooled before formal processing to remove impurities (such as hair, soil, etc.) and adjusted to a suitable processing temperature.

3. Standardization (optional): This step adjusts the fat content in milk to ensure that the final product meets specific nutritional standards or consumer preferences. This is usually achieved by separating the fat from milk and then adding it back to skim milk in proportion.

4. Homogenization (optional): In order to prevent fat from floating and forming a milk reservoir, milk is subjected to high-pressure homogenization treatment, breaking large fat particles into small particles, making the milk more stable and uniform.

5. Pasteurization: This is the core link of the entire process. There are two common methods of pasteurization: the Low Temperature Long Term (LTLT) method, which typically heats milk to 63 ° C and maintains it for 30 minutes; Heat milk to 72 ° C-75 ° C and maintain for 15-20 seconds using the High Temperature Short Term (HTST) method. Modern production lines often use the HTST method because it can more effectively preserve the flavor and nutritional value of milk.

6. Cooling: After sterilization, the milk is quickly cooled to around 4 ° C to inhibit the activity of remaining microorganisms and extend its shelf life.

7. Filling and capping: Cooled milk is fed into a sterile filling machine, which automatically fills pre disinfected bottles, paper boxes, or plastic bags and immediately seals to ensure a sterile environment.

8. Packaging and date printing: The sealed milk will be labeled with information such as production date and shelf life.

9. Final inspection and delivery: The finished product will undergo quality inspection and confirm compliance with food safety standards before being ready for delivery to retailers or directly delivered to consumers.

The entire production line is usually equipped with advanced automation equipment and monitoring systems to ensure the efficiency, safety, and hygiene of the production process.

Specifications

|

Raw material |

Liquid cow milk, goat milk, camel milk, milk powder dissolving with water |

|

Products |

Pasteurized milk, UHT milk, yogurt, flavored milk, milk drink, sour milk, butter, cheese and so on. |

|

Capacity |

Daily production : 3000L/5000L/10000L/20,000L |

|

Product package |

Aseptic pouch, Aseptic paper box, Gable Top box, plastic bottle, plastic cup, glass bottle, plastic pouch, Bulk, according to customer’s requirement |

|

Service Including |

Turnkey project service: design, manufacture, installation, commissioning, training, after-sale service and so on. |

Pasteurized milk uses fresh milk as raw material and pasteurized by pasteurization, that is, heating at 72-75 ° C for 10-15 seconds. Pasteurized milk can kill harmful bacteria in milk and preserve nutrients and pure taste. After centrifugation, standardization, homogenization, sterilization and cooling, it is poured into liquid state and directly supplied to consumers for drinking.

Three kinds of packaging of pasteurized milk:Roof bags, also known as fresh houses, pasteurized plastic bags and glass bottles.

Production range: 2td-500td

| Equipment list of pasteurized milk processing line | ||

| Name | Size | Main parameter |

| Milk reception and storage unit | ||

| Milk acceptor | 300L | SUS304 stainless steel, single layer, CIP spraying ball |

| Milk pump | 3T/H | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Single piping filter | 3T/H | SUS304, single pipe, stainless steal filter element of 100 mesh |

| Milk storage tank | 1000L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| Milk pump | 3T/H | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Blending unit | ||

| Storage tank | 500L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| Milk pump | 3T/H | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Single piping filter | 3T/H | SUS304, single, stainless steal filter element of 100 mesh |

| Plate-type exchanger | 1.5T/H | SUS304, double pipes |

| High pressure homogenizer | 500L/H | 40MPa |

| Cream separtor unit | ||

| Milk separator | 500L/H | The content of dried skim milk (%)<0.03, the speed of rotator is 8000rpm |

| Buffer container | 100L | SUS304, with a cover, single layer |

| Buffer & cooling container | 100L | SUS304, with a cover, single layer |

| Milk pump | 3T/H | SUS304, with a cover, heat insulated, dimple pad jackets |

| Butter churner | 100L | SUS304 |

| Yogurt storage, ferment and filling unit | ||

| Temporary and ferment storage tanks | 500L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| Milk pump | 3T/H | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Rotor pump | 1T/H | SUS304, hard alloy mechanical seal, adjustment speed by manual |

| Plastic pouch filling machine | ||

| Plastic cup-shaped filling machine | ||

| CIP system unit | ||

| Manual CIP system | 3×500L | SUS304, single clening circulation, with CIP pump of connected tanks |

| CIP return pump | 10T/H | SUS304, pump lift 24m ,hard alloy mechanical seal, inner shell mirror polished |

| Power system unit | ||

| Cold water equipment | 7000 kcale per hour, air cooling refrigeration | |

| Hot water boiler | 1000Kg/h, outlet temperature is 90°C | |

| Installation system | Stainless steel piping system,power piping system, electric controlling box, electric installation material, installation and commissioning | |

Pasteurized Milk Processing Line installation and debugging

The installation and debugging of a pasteurized milk processing line involves several stages and requires careful planning, precision, and adherence to strict hygiene standards. Below is a general outline of the process:

1. Site Preparation and Layout Planning

• Site Selection: Choose an area with proper infrastructure for water supply, drainage, electricity, and waste management.• Layout Design: Plan the layout considering the flow of raw materials to finished products, including areas for receiving, storage, pasteurization, filling, packaging, and refrigeration.• Hygienic Design: Ensure all surfaces that will come into contact with milk are made of food-grade materials and can be easily cleaned and sanitized.

2. Equipment Arrival and Inspection

• Unpacking and Inspection: Check all equipment for any damages during transportation.• Verification: Confirm that the equipment matches the specifications and complies with local health and safety regulations.

3. Installation

3.1 Plumbing and Piping• Install pipelines for milk intake, pasteurization, cooling, and CIP (Clean-in-Place) systems. Use stainless steel or food-grade plastic pipes and fittings to avoid contamination.3.2 Electrical and Control Systems• Connect electrical wiring for motors, sensors, and control panels according to the manufacturer's instructions and local electrical codes.• Configure control systems for temperature control, flow monitoring, and alarms.3.3 Equipment Assembly• Assemble and install key components such as: • Receiving and Storage Tanks: For holding raw milk before processing.• Pasteurizer: The heart of the system, designed to heat-treat milk to destroy pathogens.• Homogenizer: To evenly distribute fat particles for consistency.• Cooling System: To rapidly cool the milk after pasteurization.• Filling and Packaging Machines: For bottling or packing the milk.3.4 Hygienic Fittings and Valves• Install sanitary valves, filters, and traps to facilitate cleaning and prevent contamination.

4. Commissioning and Testing

• Leak Tests: Perform pressure tests on all pipelines and tanks to ensure there are no leaks.• Equipment Calibration: Calibrate temperature sensors, flow meters, and other instruments for accuracy.• CIP System Testing: Run the cleaning cycle to verify its effectiveness in cleaning all parts of the system.• Trial Runs: Conduct test runs using water or a non-food substitute to check the entire process flow, from intake to packaging, ensuring all equipment functions correctly.

5. Sanitization and Hygiene Protocol Implementation

• Sanitize Equipment: Thoroughly clean and sanitize all equipment before the first production run.• Establish SOPs: Develop Standard Operating Procedures (SOPs) for routine cleaning, sanitizing, and maintenance.

6. Training

• Train operators and maintenance staff on the operation, cleaning, and safety protocols of the equipment.7. Final Approval and Documentation• Obtain necessary permits and certifications from local health authorities.• Document all installation, testing, and training processes for future reference and compliance purposes.

Pasteurized Milk Processing Line Customized case

When designing a pasteurized milk processing production line, every step needs to be carefully planned to ensure the safety, nutrition, and taste of the final product. The following is a typical customized case of pasteurized milk processing production line, covering the entire process from raw material reception to finished product packaging:

1. Raw material reception and storage

• Milk storage system: Install stainless steel milk storage tanks with automatic temperature control to receive fresh milk from the ranch and maintain low temperature storage to prevent bacterial growth.

Raw material testing: Equipped with rapid testing equipment for raw milk, conduct quality testing on each batch of raw milk, including fat, protein content, microbial indicators, etc.

2. Preprocessing

• Milk Purifier: Use a centrifugal milk purifier to remove impurities such as dirt, hair, etc. from raw milk.

Cooling system: The milk is cooled to around 4 ° C to prepare for subsequent processing.

Standardization system: Adjust the proportion of fat and non fat milk solids in milk according to product specifications to ensure product consistency.

3. Pasteurization

Pasteurization unit: Customize a suitable pasteurization system, commonly using two methods: Low Temperature Long Term (LTLT) or High Temperature Short Term (HTST). HTST is usually kept at 72 ° C-75 ° C for 15-20 seconds, which can effectively kill and eliminate most harmful microorganisms while preserving the natural flavor and nutritional components of milk.

Aseptic transportation: The sterilized milk is transported to the filling process through sterile pumps and pipelines to avoid secondary contamination.

4. Filling and sealing

Aseptic filling machine: Select or customize aseptic filling equipment according to product packaging specifications (such as bottled or boxed) to ensure that filling is completed in a sterile environment.

• Sealing system: Automatically completes the sealing process and can be configured with different types of sealing devices to match different packaging materials.

5. Cooling and Storage

• Rapid cooling: The filled milk is immediately cooled rapidly by cold water or ice water to around 4 ° C for storage and subsequent transportation.

Warehouse management: Establish a cold chain warehousing system to ensure that finished products are stored at suitable temperatures until shipment.

6. Packaging and Logistics

• Automatic packaging line: Design a packaging line based on product characteristics, including automatic packing, sealing, labeling, and palletizing, to improve efficiency and reduce manual operations.

Traceability system: Implement a product traceability system, assigning unique codes to each batch of products for quality tracking and management.

7. Hygiene and Quality Control

CIP cleaning system: Configure on-site cleaning (CIP) systems for each major equipment to ensure thorough cleaning and disinfection of the equipment before and after production.

Quality inspection station: Set up online quality inspection equipment at key nodes to monitor various indicators during the production process, such as microbial content, physical and chemical properties, etc.

8. Automation and informatization

PLC control system: The entire line adopts programmable logic controller (PLC) for automation control, improving production efficiency and accuracy.

MES system: Implement a manufacturing execution system to achieve production plan management, production data collection and analysis, and improve management efficiency.

Through the above customized plan, the pasteurized milk production line can efficiently and safely produce high-quality pasteurized milk products, meeting the needs of different markets and consumers.