An ice cream processing line is a series of equipment and machinery used to manufacture ice cream in a commercial setting. The line typically includes the following steps:

Mixing: The raw ingredients, such as milk, cream, sugar, stabilizers, and flavorings, are combined in a large mixing tank. The ingredients are blended together to form the ice cream base.

Homogenization: The ice cream base is passed through a homogenizer, which breaks down fat globules and ensures a smooth and consistent texture.

Pasteurization: The ice cream base is heated to a specific temperature to kill any harmful bacteria present. This step is crucial for food safety.

Aging: The ice cream base is allowed to age at a controlled temperature for a specific period. This aging process enhances the texture and flavor of the ice cream.

Flavoring and Additions: Once the ice cream base has aged, additional flavorings, such as fruit purees, chocolate chips, or nuts, can be added. These additions are mixed into the base to create a flavored ice cream.

Freezing: The ice cream base is pumped into a continuous freezer, where it is rapidly frozen while being agitated. This freezing process creates small ice crystals and incorporates air, giving the ice cream its creamy and smooth texture.

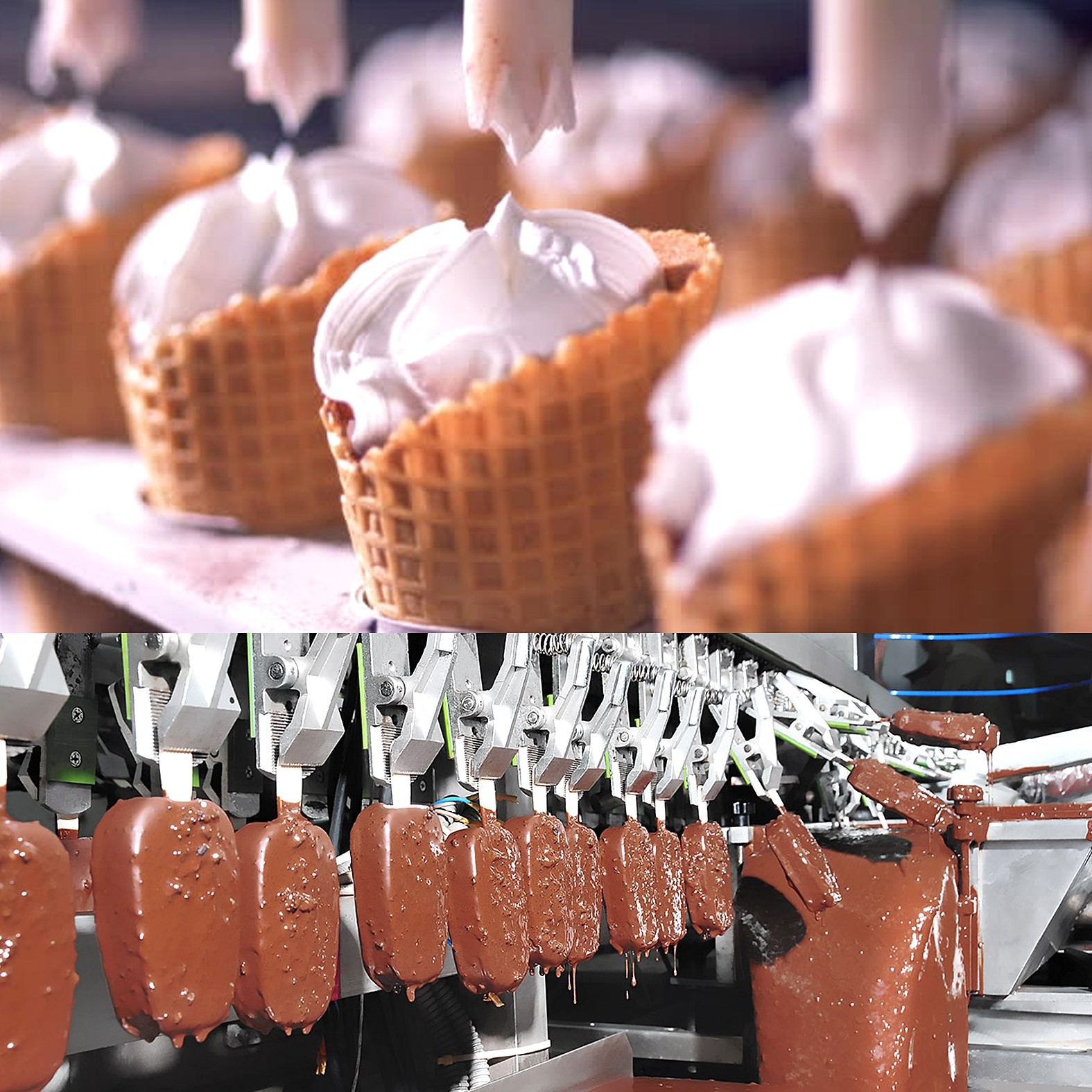

Packaging: The frozen ice cream is then transferred to a packaging machine, where it is filled into containers, such as tubs or cones. The packaging is sealed to prevent air and moisture from entering.

Hardening: The packaged ice cream is moved to a hardening room or blast freezer, where it is stored at very low temperatures to further solidify and stabilize the product.

Labeling and Coding: The packaged ice cream containers are labeled with important information, such as the flavor, ingredients, nutritional content, and expiration date. Coding is applied to track production and ensure traceability.

Storage and Distribution: The finished ice cream is stored in a frozen storage area before being distributed to retailers or consumers.

Quality Control: Throughout the processing line, quality control tests, such as sensory evaluation, viscosity measurement, and microbiological analysis, are conducted to ensure the ice cream meets safety and quality standards.

Cleaning and Sanitization: The processing line and equipment are thoroughly cleaned and sanitized between production runs to maintain food safety and prevent contamination.

Each step in the ice cream processing line is carefully controlled to create a consistent and delicious end product. Modern processing lines include automation and advanced technology to increase efficiency and maintain product quality.

Production technology:

Preheating → mixing of ingredients → sterilizing and homogenizing cooling (< + 5 ℃ ripening > 4 hours) → continuous freezing (air-3 ℃ - 6 ℃) → adding dry materials and fruit mixture → injection molding, injection and extrusion into cup or egg roll (flavoring material) → freezing → continuous hardening → (- 20 ℃) → frozen storage - 25 ℃ (0-9 months)

Raw materials and products of Ice Cream Processing Line

1. Raw materials

In the ice cream production line, various raw materials are used, including basic raw materials and auxiliary raw materials. The following is a detailed list of raw materials:

• Dairy products:

• Whole milk: Provides rich protein and fat, and is one of the main ingredients of ice cream.

• Cream: Increases the fat content of ice cream, making it taste richer and smoother.

• Whey powder: Increases the solid content and improves the stability of ice cream.

• Milk powder: Increases the solid content and improves the nutritional value of ice cream.

• Sugars:

• Sucrose: The main sweetener, provides sweetness and increases the solid content of ice cream.

• Glucose syrup: Increases the viscosity of ice cream, prevents ice crystal formation, and improves the taste.

• Corn syrup: Increases the softness of ice cream and prevents crystallization.

• Stabilizer:

• Carrageenan: Improves the stability of ice cream and prevents melting.

• Gelatin: Increases the viscosity of ice cream and improves the taste.

• Guar gum: Improves the stability and taste of ice cream.

• Emulsifier:

• Lecithin: Improves the structure of ice cream and prevents fat separation.

•Monoglyceride: Improve the fineness of ice cream and prevent ice crystal formation.

•Flavor and color:

•Flavor: Such as vanilla flavor, chocolate flavor, provide different flavors.

•Color: Such as natural color (carotene, beet red), synthetic color, provide different colors.

•Fruits and nuts:

•Fresh fruits: Such as strawberry, blueberry, mango, used to make fruity ice cream.

•Jam: Used to increase the flavor and texture of ice cream.

•Nuts: Such as almonds, walnuts, peanuts, increase the taste and nutritional value of ice cream.

•Other auxiliary materials:

•Egg yolk: Increase the egg and milk flavor of ice cream and improve the taste.

•Alcohol: Such as mint liquor, rum, used to make special flavor ice cream.

•Salt: A small amount of salt can enhance the sweetness of ice cream.

2. Products

The ice cream production line can produce many different types of ice cream products. The following are some common product types:

•Ordinary ice cream: Basic ice cream, mainly composed of dairy products, sugars, stabilizers and emulsifiers.

•Fruit-flavored ice cream: such as strawberry ice cream, blueberry ice cream, and mango ice cream, by adding fresh fruits or jams, a variety of flavors are available.

•Chocolate ice cream: Made by adding chocolate powder or chocolate liquid, it provides a rich chocolate flavor.

•Nut ice cream: such as almond ice cream and walnut ice cream, by adding chopped nuts, the taste and nutritional value are increased.

•Low-fat ice cream: By reducing the fat content, it is suitable for people who pursue a low-fat diet.

•Sugar-free ice cream: Using sugar substitutes (such as stevia, erythritol) instead of sucrose, it is suitable for diabetics or people on a low-sugar diet.

•Organic ice cream: Using organic dairy products and organic ingredients, it is produced in accordance with the standards of organic agriculture and does not contain chemical pesticides and hormones.

•Plant-based ice cream: such as soy milk ice cream, almond milk ice cream, and oat milk ice cream, suitable for lactose intolerant or vegetarians.

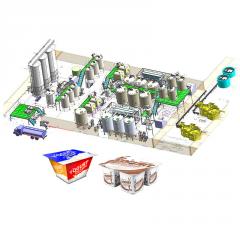

1. Ice cream mix preparation module containing

2. Water heater

3. Mixing and processing tank

4. Homogeniser

5. Plate heat exchanger

6. Control panel

7. Cooling water unit

8. Ageing tanks

9. Discharge pumps

10. Continuous freezers

11. Ripple pump

12. Filler

13. Manual Can filler,

14. Wash unit

DESCRIPTION

-Formulation:

The ingredients used in ice cream production are: fat;milk solids-non-fat (MSNF);sugar/non-sugar sweetener;emulsifiers/stabilisers;flavouring agents;colouring agents.

-Weighing, measuring and mixing:

Generally speaking, all dry ingredients are weighed, whereas liquid ingredients can be either weighed or proportioned by volumetric meters.

-Homogenisation and pasteurisation:

The ice cream mix flows through a filter to a balance tank and is pumped from there to a plate heat exchanger where it is preheated to 73 – 75deg for homogenisation at 140 – 200 bar, the mix is pasteurised at 83 – 85deg for about 15 seconds then cooled down to 5deg and transferred to an ageing tank.

-Ageing:

The mix must be aged for at least 4 hours at a temperature between 2 to 5degc with continuous gentle agitation. Ageing allows time for the stabiliser to take effect and the fat to crystallise.

-Continuous freezing:

•to whip a controlled amount of air into the mix;

•to freeze the water content in the mix to a large number of small ice crystals.

-Filling in cups, cones and containers;

-Extrusion of sticks and stickless products;

-Moulding of bars

-Wrapping and packaging

-Hardening and cold storage

|

Equipment list for 500l/h mini ice cream production machine |

|||

|

No. |

Name |

Size |

Main technology parameter |

|

1 |

High speed mixing tank |

v=300l |

Sus304, single layer, high speed mixer 2900rpm, full open removable cover, breath valve, digital thermometer, adjustable legs, sample valve |

|

2 |

Centrifugal pump |

q=5t/h |

Sus304,pump head 24m,hard alloy mechanical seal |

|

3 |

Tub filter |

q=3t/h |

Sus304,100 mesh |

|

4 |

High pressure homogenizer |

q=500l/h |

Sus304,25mpa |

|

5 |

Plate exchanger |

q=500l/h |

Sus304 |

|

6 |

Ice cream aging tank |

v=500l |

Sus304 stainless steel,heat insulated,heating or cooling jacket,top off-center vertical agitator,conical head,airtight manhole,breather valve,digital readout thermometer,supporters with adjustable feet |

|

7 |

Centrifugal pump |

q=5t/h |

Sus304,pump lift 24m,hard alloy mechanical seal,inner shell bright-polished |

|

8 |

Ice cream freezer machine |

q=500l/h |

Sus304,include refrigeration system |

|

9 |

Ice cream filling machine |

q=500l/h |

Sus304,roll icecream filling machine |

|

10 |

Cip system |

q=10t/h |

Sus304,0.5tx3 |

|

11 |

Cip return pump |

q=10t/h |

Sus304,pump head 20m,hard alloy mechanical seal |

|

12 |

Boiler |

q=500l/h |

sus304,electric heating type |

|

13 |

Refrigerator |

Air-cooled compressor,with fron as chilling medium,20000kcal |

|

|

14 |

Container for glycol water |

v=500l |

Sus304 stainless steel material,pu heat insulation,thermometer,adjustable feet |

|

15 |

Centrifugal pump |

q=3t/h |

Sus304,pump head 24m,hard alloy mechanical seal |

|

16 |

Instant cool room |

v=25m3 |

Cool with freon,working at -28°C |

|

17 |

Electrical control pannel |

Control all the machines of the mini unit |

|

|

18 |

Fittings and valves |

Juice pipe,glycol pipe,freon pipe |

|

Customized Ice Cream Processing Line Solution

Designing a customized ice cream production line requires consideration of multiple aspects, including production processes, equipment selection, raw material and product characteristics, and the layout of the production line. Here is a detailed solution:

1. Preparation of raw materials for production process

• Reception and storage of raw milk: Receive fresh raw milk and store it in a low-temperature environment.

• Pre treatment: Filter, homogenize, and standardize the raw milk to ensure it meets production requirements.

Mixing and Ingredients

Mixing: Mix raw milk, sugar, stabilizers, emulsifiers, etc. evenly to make ice cream base material.

Heating: Heat the base material to 65-70 ° C for 30 minutes to sterilize and dissolve the stabilizer.

Homogenization

Homogenization treatment: By using a high-pressure homogenizer, the fat particles in the base material are evenly distributed, improving the delicacy and stability of the ice cream.

cooling

• Cooling: Quickly cool the homogenized base material to 4-5 ° C to prevent bacterial growth.

ageing

Aging: Allow the cooled base material to stand at 4-5 ° C for 4-8 hours to enhance its structure and taste.

Freeze

• Freezing: Send the aged base material into the freezing machine, stir at low temperature, and inject air to form a soft ice cream.

Molding and Packaging

• Molding: Pour the frozen ice cream into a mold or packaging container.

• Packaging: Pack the ice cream to ensure a good seal.

freezing

• Freezing: Put the packaged ice cream into the freezer and quickly freeze it to below -18 ° C to ensure its quality and shelf life.

2. Equipment selection: Main equipment

Raw milk receiving and storage equipment: storage tanks, cooling systems.

Preprocessing equipment: filters, homogenizers, standardization equipment.

Mixing and batching equipment: mixing tank, heating tank.

Homogenization equipment: High pressure homogenizer.

• Cooling equipment: Plate heat exchangers, cooling towers.

Aging equipment: aging tank.

• Freezing equipment: freezing machine.

• Forming and packaging equipment: forming machines, packaging machines.

• Freezing equipment: freezer, quick freezing tunnel.

3. Raw materials and product raw materials

Raw milk: Fresh, high-quality raw milk.

Sugar: white sugar, glucose syrup, etc.

Stabilizers: such as carrageenan and guar gum, used to improve the texture and stability of ice cream.

Emulsifiers: such as monoglycerides, used to improve the taste of ice cream.

Spices and colors: used to make ice cream of different flavors and colors.

Fruits and nuts: used to make sandwich or mixed flavored ice cream.

product

Ordinary ice cream: a basic ice cream without additives.

Flavored ice cream: ice cream with various spices and fruits added.

Low fat or skimmed ice cream: ice cream suitable for healthy eating needs.

Functional ice cream: ice cream containing functional ingredients such as prebiotics and probiotics.

4. Customized demand production capacity

Capacity selection: Select equipment with appropriate capacity based on the size and demand of the factory.

Flexibility: Design adjustable production lines to meet the production needs of different products.

Product diversity

Multi flavor production: Design production lines for multiple flavors to meet the needs of different markets.

Special requirements: Provide ice cream production lines with special requirements such as low-fat, sugar free, organic, etc.

Degree of automation

• Automation level: Select different levels of automation equipment based on budget and management needs.

Information management: Introduce information management systems to improve production efficiency and management level.

Environmental requirements

Wastewater treatment: Design a wastewater treatment system that complies with local environmental regulations.

• Waste management: Reasonably handle the waste generated during the production process.

hygienic standard

GMP and HACCP: Ensure that all equipment and facilities comply with hygiene standards such as GMP and HACCP.

• Cleaning and maintenance: Regularly clean and maintain the equipment to ensure the hygiene of the production environment.

5. Design and plan the overall layout

Raw material receiving area: used for receiving and inspecting the quality of raw materials.

Storage area: used for storing raw materials and finished products.

Processing area: including processes such as mixing, heating, homogenization, cooling, aging, and freezing.

• Packaging area: used for packaging and labeling of finished products.

Finished product storage area: used for storing finished products and preparing them for shipment.

• Laboratory: used for quality control and testing.

Office and Rest Area: Provides a place for employees to work and rest.

6. Technical support

Automation and informatization: Introduce automated production lines and information management systems to improve production efficiency and management level.

• Training: Regularly train employees to ensure they master the latest technology and operating procedures.

After sales service: Provide comprehensive after-sales service and technical support to ensure the normal operation of the production line.