Description:

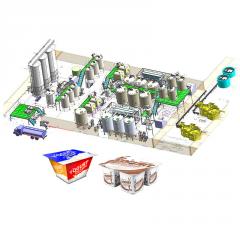

UHT milk processing line refers to the equipment used in the production of UHT (Ultra High Temperature) milk. UHT milk is a type of milk that has been pasteurized at a very high temperature for a short period of time, typically around 135-150°C for 2-5 seconds. This process kills harmful bacteria and extends the shelf life of the milk without the need for refrigeration.

A UHT milk processing line typically includes the following steps:

-

Raw milk reception: The raw milk is received and tested for quality and safety.

-

Pre-treatment: The milk is preheated to remove any impurities and to standardize the fat content.

-

Homogenization: The milk is passed through a homogenizer to break down the fat globules and create a uniform texture.

-

Heat treatment: The milk is heated to a very high temperature (usually through indirect heating methods like plate heat exchangers) for a very short time to kill any harmful bacteria and extend the shelf life.

-

Cooling: The milk is rapidly cooled after the heat treatment to bring it to a safe temperature.

-

Aseptic packaging: The milk is packaged in aseptic containers, such as cartons or bottles, to maintain its sterility and extend its shelf life.

-

Quality control: The packaged milk is tested for quality, safety, and shelf stability before being released for distribution.

UHT milk processing lines are typically highly automated and require advanced technology and expertise to ensure the quality and safety of the final product. They are commonly used in large-scale dairy processing facilities.

UHT milk process: milk transporting tank or vessels, milk filter and collection tank; cooling and storaging tank(milk chilly tank), Mixing/Blending and milk standardization, cream separation, UHT sterilizer(tubular type or plate type) homogenization, degassing, and filling.

In the UHT (Ultra High Temperature Instant) milk processing production line, raw materials and products are the starting and ending points of the entire production process, including:

Raw material

Fresh milk: High quality fresh milk is the basic raw material for UHT milk production lines, requiring no antibiotic residues and low bacterial count. Suppliers are usually carefully screened ranches to ensure the quality and safety of milk sources.

Intermediate products (processing)

Pre treated milk: Raw milk is first filtered and purified to remove impurities, and then the proportion of fat and solid non fat (SNF) is adjusted through standardization to meet specific product specifications.

Pasteurized milk: Before UHT treatment, milk is usually pasteurized to eliminate most harmful microorganisms and prepare for UHT treatment. But this step may be omitted in some UHT processes.

Product

UHT sterilized milk: Milk treated with UHT is heated to 135 ° C to 150 ° C in a very short period of time (usually a few seconds) and then rapidly cooled. This method can effectively kill all microorganisms without the need for preservatives, while maintaining the natural flavor and nutritional value of milk. UHT milk can be stored at room temperature for several months without spoiling.

UHT flavored dairy products: In addition to pure milk, the production line can also produce various flavored UHT dairy products, such as chocolate milk, strawberry milk, etc., by adding seasonings and sugar after sterilization.

UHT milk powder: some UHT treated milk will be further processed into milk powder, which will go through such processes as concentration, spray drying, etc., to facilitate storage and transportation.

The products produced by UHT milk processing lines are widely used in households, catering services, and emergency rescue supplies due to their convenience, long shelf life, and no need for refrigeration.

Features and advantages:

1. Efficient production: The processing capacity can range from 2T/day to 1000T/day. The UHT milk processing line adopts advanced production processes and equipment, which can achieve large-scale production in a short period of time. It has highly automated functions, with PLC controlling the entire production line, saving labor and facilitating production management.

2. Long term storage: UHT milk is stored through ultra-high temperature treatment, so it can be stored for a long time at room temperature without the need for refrigeration. This makes UHT milk a very convenient and economical choice, especially for areas without perishable storage conditions.

3. High quality products: High standard design, manufacturing, and engineering installation requirements ensure first-class quality of finished products in dairy processing lines. UHT milk, after high-temperature treatment, can effectively kill bacteria and microorganisms, thereby extending the shelf life of the product. This means that consumers can enjoy fresh, hygienic, and high-quality milk products.

4. International certification: UHT milk processing lines usually comply with international food safety and quality standards, such as ISO 9001 and HACCP certification. These certifications can increase consumer trust in products and make them more competitive in domestic and international markets.

5. Diversified products: UHT milk processing line can produce various milk products with different flavors and additives, such as chocolate milk, strawberry milk, and vitamin fortified milk. This diverse choice can meet the needs and taste preferences of different consumers.

6. Environmental sustainability: The UHT milk processing line reduces energy consumption and wastewater discharge during the production process. Fully automatic CIP cleaning ensures that the entire production line equipment meets food hygiene and safety requirements. The UHT milk processing line is more environmentally friendly and sustainable, meeting the requirements of modern society for sustainable development and environmental protection.

|

Equipment list DAIRY PRODUCTION plant (pasteurized milk\yogurt\cheese\cream\butter) |

||

| NO. | NAME | MAIN TECHNOLOGY PARAMETER |

| 1 | MILK RECEIVE\STORAGE\AND CREAM SEPARETOR UNIT | |

| 2 | Electron pound scale | maximum weighing 500KG |

| 3 | Milk weighing tank | made of SUS stainless steal,single layer,product feeded in through 40 mesh filter net,CIP cleaning ball |

| 4 | Milk acceptor | SUS304 stainless steel,single layer,CIP cleaning ball |

| 5 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 6 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 7 | Dish separator | auto residue discharge |

| 8 | chiling tank | SUS304 stainless steel,alveolate jacket,attached with compressor |

| 9 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 10 | PREPARING UNIT | |

| 11 | Blending tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 12 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 13 | Mini set of plate-type heat exchanger | SUS304 stainless steel,two stages, |

| 14 | High speed emulsification tank | SUS304 stainless steel,heat insulated,bottom high speed emulsifier,digital readout thermometer,supporters with adjustable feet |

| 15 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 16 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 17 | Sterilizing,homogenizing unit | |

| 18 | UHT sterilizer | tub-type,sterilzing temperature 137 C,holding time 4S,full automatic control |

| 19 | High pressure homogenizer | 40MPa,(starting box included) |

| 20 | Temperature holding | SUS304,holding 300S |

| 21 | Distributing board | SUS304,3 holes |

| 22 | Cheese\butter processing unit | |

| 23 | Bufferying tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 24 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 25 | Cream seperator | |

| 26 | Bufferying container | SUS304,with cover |

| 27 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 28 | Butter-churner | SUS304,stepless timing |

| 29 | Cheese vat | SUS304,with heating jacket and insising device |

| 30 | Pressor | SUS304,6 heads |

| 31 | Mould | SUS304,10L,with cover |

| 32 | Yogurt fermentation unit | |

| 33 | Fermentation tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 34 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 35 | Plate cooler | SUS304,single stage,milk discharge at 4degreeC |

| 36 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 37 | Filling unit | |

| 38 | Higher position tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 39 | Pasteurized milk filling machine | |

| 40 | Yogurt filling machine | |

| 41 | CIP system | |

| 42 | Semi-auto CIP system | outer coat of SUS304 stainless steel material,inner shell of SUS316,single cleaning way,Concentrated acid/alcali tank adding system based on US technology, 100L×2 acid/alcali Concentrate tanks |

| 43 | CIP return pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 44 | Installation part | project installation and commissioning |

UHT Milk Processing Line installation and debugging

The installation and debugging of an Ultra-High Temperature (UHT) milk processing line is a complex process that requires precision, technical expertise, and adherence to strict hygiene standards. UHT processing involves heating milk to a very high temperature for a short period to eliminate all bacteria and spores, ensuring long shelf life without the need for refrigeration until opened.

Here's a general outline of the steps involved in installing and debugging such a system:

1. Site Preparation• Infrastructure Check: Ensure the facility has appropriate water supply, electricity, drainage, and ventilation systems.• Civil Works: Prepare the foundation according to the manufacturer's specifications for equipment placement.• Hygienic Design: Implement hygienic design principles, including easy-to-clean surfaces, coved corners, and appropriate floor slopes.

2. Equipment Unpacking and Inspection• Carefully unpack all equipment and inspect for any damages during transportation.• Verify that all components match the purchase order and manufacturer's documentation.

3. Installation• Piping and Plumbing: Install pipelines for milk intake, product circulation, CIP (Clean-in-Place) systems, and waste disposal, ensuring they meet hygiene standards.• Equipment Placement: Position pasteurizers, heat exchangers, homogenizers, filling machines, and other components as per the layout plan.• Electrical and Control Systems: Connect electrical wirings and install control panels, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems.• Instrumentation: Calibrate temperature sensors, flow meters, pressure gauges, and other instruments.

4. Commissioning and Debugging• Individual Component Testing: Test each machine separately to ensure they function correctly. This includes running water and steam through pipes to check for leaks.• System Integration: Integrate all components and run simulations to test the entire process flow from milk reception to packaging.

• CIP System Testing: Validate the Clean-in-Place system to ensure effective cleaning of all contact parts without disassembly.

• Sterilization: Perform initial sterilization of the whole system before introducing milk.• Trial Runs: Conduct trial runs with water, then with milk, monitoring all parameters (temperature, flow rates, pressures) and adjusting as necessary.• Quality Control: Collect samples during trials and test for microbiological and sensory quality.

5. Training and Documentation• Operator Training: Train staff on operation, maintenance, hygiene protocols, and troubleshooting.• Documentation: Compile operation manuals, maintenance schedules, and safety guidelines. Record all data and keep it for future reference.

6. Final Approval and Handover• Once the system consistently meets performance and quality standards, obtain necessary approvals from regulatory bodies if applicable.

• Conduct a final handover to the production team, ensuring they are comfortable operating and maintaining the system independently.It's crucial to work closely with the equipment supplier or manufacturer throughout the process, as they can provide technical assistance, specialized tools, and critical operational knowledge.

Customization of UHT milk processing production line

When customizing a UHT milk processing production line, multiple details need to be considered to ensure that the production line can efficiently and safely meet specific production needs and product standards. Here are some key customization details:

1. Capacity demand: Based on the expected market size and sales forecast, determine the amount of milk that the production line needs to process per hour or per day, which directly affects the size and configuration of the equipment.

2. Product type: In addition to standard UHT pure milk, is it necessary to produce various products such as flavored milk, high calcium milk, low-fat milk, etc? Different products may require different ingredient systems, mixing devices, and packaging methods.

3. Automation level: The automation level of the entire process, from raw material receiving, pretreatment, UHT sterilization, filling to packaging and palletizing. High automation can reduce manual intervention, improve efficiency and hygiene standards.

4. Aseptic environment design: UHT production lines have extremely high requirements for sterile environments, requiring customized design of air purification systems, sterile rooms, and sterile transmission systems to ensure aseptic control throughout the entire production process.

5. Energy efficiency: Considering the energy consumption of the production line, choose energy-saving and efficient heating and cooling systems, such as using plate heat exchangers instead of tube heat exchangers, and systems that recycle steam and cooling water.

6. Quality control system: Integrated online detection equipment, such as pH meters, temperature sensors, flow rate monitoring, etc., to ensure stable product quality and compliance with food safety standards.

7. Packaging flexibility: Choose appropriate packaging forms based on market demand, such as paper boxes, plastic bottles, Tetra Pak bags, etc., and consider the compatibility and fast conversion ability of packaging machines to adapt to different packaging specifications.

8. Cleaning and Maintenance: Design equipment that is easy to clean and disinfect, as well as CIP (Cleaning in Place) and SIP (Sterilization in Place) systems, to ensure the continuous hygiene of the production environment.

9. Traceability system: Implement a complete batch tracking and management software that can trace every step from raw materials to finished products to meet food safety regulatory requirements.

10. Space layout: Based on the actual space of the factory, customize the optimized production line layout plan to ensure smooth material flow while leaving space for future development and expansion.

Every detail requires close communication, personalized design, and adjustment to ultimately achieve a UHT milk processing production line that meets specific production needs and standards.