1. Overview: Flavored Milk Drinks Processing Plant refers to a facility that specializes in producing milk drinks with various flavors. These plants receive fresh milk and process it into milk drink products with various flavors by adding different natural or artificial flavorings, sweeteners and other ingredients such as fruit juice, chocolate powder, etc. to meet the preferences and market needs of different consumers.

2. Main Processes:

• Raw Material Receiving and Inspection:

• After fresh milk is transported from the dairy farm to the processing plant, it is first subjected to strict quality inspection to ensure that it meets food safety standards.

• Other ingredients such as sugar, flavors, pigments, etc. are also subject to strict incoming inspection.

• Pretreatment:

• Filtration and Standardization: Remove impurities and adjust the fat content to meet the required formula requirements.

• Pasteurization or Ultra High Temperature Sterilization (UHT): Heat the milk to kill potential harmful microorganisms and extend the shelf life.

• Mixing and Blending:

• Mix the pretreated milk with other ingredients in a specific proportion.

•Add vitamins, minerals or other functional ingredients to increase the nutritional value of the product.

•Homogenization:

•Use a homogenizer to break up the fat globules in the mixture to prevent stratification and make the product more stable and smooth.

•Cooling:

•The mixture after heat treatment needs to be quickly cooled to a suitable temperature, usually below 4°C, to maintain taste and quality.

•Packaging:

•The cooled flavored milk beverage is filled into various forms of packaging containers, such as cartons, plastic bottles, glass bottles, etc., ready for distribution.

•Storage and distribution:

•The finished product is stored in a low temperature environment and quickly distributed to retailers or consumers through a cold chain logistics system.

a. Raw material receiving and inspection equipment:

•Quality testing instruments: Used to test the quality of fresh milk and other ingredients, including fat content, protein content, microbiological indicators, etc.

•Automatic sampler: Ensure that each incoming goods can be effectively sampled and tested.

b. Pretreatment equipment:

•Filters and centrifuges: Used to remove impurities in milk and adjust the fat content.

•Pasteurizer or ultra-high temperature sterilization (UHT) equipment: Heat treat milk to kill potential harmful microorganisms and extend shelf life.

c. Mixing and blending equipment:

•Mixing tank: Used to mix milk and other ingredients in a specific proportion.

•Batching system: Includes precise metering devices to ensure that each ingredient is added accurately according to the formula.

•Pipeline transportation system: Connects various processing units to ensure smooth material transmission.

d. Homogenization equipment:

•Homogenizer: Breaks up the fat globules in the mixed liquid to prevent stratification and make the product more stable and smooth.

e. Cooling equipment:

•Cooling tank: Used to quickly reduce the temperature of the mixed liquid after heat treatment. It usually adopts a jacket design with cooling water or refrigerant circulation inside.

•Plate heat exchanger: Can efficiently exchange heat and quickly cool down.

f. Packaging equipment:

•Automated filling production line: Including carton filling machine, plastic bottle filling machine, glass bottle filling machine, etc., choose the appropriate equipment according to different packaging needs.

•Sealing machine and labeling machine: Complete the sealing and labeling of packaging containers.

g. Storage and distribution equipment:

•Refrigerated and frozen storage facilities: Used for storage of finished products in low temperature environments to ensure product quality.

•Cold chain logistics vehicles: Ensure that the product maintains a suitable temperature during transportation.

h. Quality control and testing equipment:

•Laboratory analysis instruments: Used for quality testing of finished products to ensure compliance with food safety standards.

•HACCP system monitoring equipment: Real-time monitoring of key control points in the production process to ensure that every link is under control.

i. Cleaning and maintenance equipment:

•CIP (cleaning in place) system: used for automatic cleaning of equipment, reducing manual intervention and improving hygiene standards.

•Disinfection equipment: ensures the sanitary conditions of production equipment and environment to prevent cross contamination.

4. Safety and quality control:

•Flavored milk beverage processing plants must strictly comply with food safety regulations and implement the HACCP (Hazard Analysis and Critical Control Points) system to ensure that every production link is under control.

•Periodically sample and test finished products to ensure that they meet relevant national and industry standards.

5. Innovation and trends:

•Healthy trends: Consumers are paying more and more attention to health, so functional flavored milk beverages such as low sugar, no added preservatives, and rich in probiotics are gradually becoming popular.

•Environmentally friendly packaging: Using recyclable materials or reducing packaging waste has become one of the directions of industry development.

•Personalized customization: Some brands have begun to provide customized services, allowing consumers to choose their favorite flavor combinations to enhance the consumer experience.

6. Flavored Milk Drinks Processing Plant Raw Materials and Products

1. Raw Materials The raw materials required to produce flavored milk drinks mainly include the following categories:

1. Fresh milk:

• Source: Fresh raw milk purchased directly from dairy farms.

• Quality requirements: Must meet food safety standards and undergo strict quality testing to ensure that it is free of pollution and pathogens, and that the fat content and protein content meet specific requirements.

2. Sweeteners:

• Sugars (such as sucrose, glucose, fructose): provide sweetness and improve taste.

• Low-calorie sweeteners (such as aspartame, erythritol, stevia): used to produce low-sugar or sugar-free products to meet health needs.

3. Flavors and flavorings:

• Natural flavors (such as strawberry flavor, chocolate powder, vanilla extract): give products a unique flavor.

• Artificial flavors: added as needed to enhance or adjust the flavor of the product.

4. Pigments:

• Natural pigments (such as fruit juice, vegetable juice, anthocyanins, etc.): used to increase the visual appeal of the product.

•Synthetic coloring: used in some cases, but must comply with food safety regulations.

5. Emulsifiers and stabilizers:

•Common emulsifiers (such as lecithin, monoglyceride): help maintain the stability of the mixture and prevent stratification.

•Common stabilizers (such as carrageenan, agar, guar gum): improve the texture and shelf life of the product.

6. Vitamins and minerals:

•Common added ingredients (such as vitamin A, D, calcium, iron, etc.): increase the nutritional value of the product and cater to healthy consumption needs.

7. Other functional ingredients:

•Probiotics: contribute to intestinal health and are often used in functional beverages.

•Dietary fiber: increase satiety and promote digestion.

2. Products

There are many types of flavored milk beverages, which are mainly divided into the following categories:

1. Ordinary flavored milk:

•Typical flavors: strawberry, chocolate, vanilla, coffee, etc.

•Features: suitable for mass consumption, rich taste, and balanced nutrition.

2. Low-sugar/sugar-free milk drinks:

•Features: Low-calorie sweeteners are used, suitable for health-conscious consumers.

•Target market: Fitness enthusiasts, diabetics, etc.

3. Functional milk drinks:

•Probiotic milk: Add probiotics to help maintain intestinal health.

•High-calcium milk: Rich in calcium, suitable for children and the elderly.

•Fortified vitamin milk: Add multiple vitamins to enhance immunity.

4. Organic milk drinks:

•Features: Use organically certified raw materials, do not contain harmful chemicals, and are more environmentally friendly and healthy.

•Target market: Consumers who pay attention to organic food.

5. Customized milk drinks:

•Features: Allow consumers to choose different flavor combinations, and even customize packaging designs to enhance personalized experience.

•Target market: Young consumers who pursue uniqueness and personalization.

3. Critical control points in the production process In order to ensure the quality and safety of the products, the flavored milk beverage processing plant sets up multiple critical control points (HACCP) throughout the production process, including:

•Raw material inspection: Ensure that each batch of milk and other ingredients meets quality standards.

• Heat treatment process: effectively kill harmful microorganisms through pasteurization or ultra-high temperature sterilization (UHT).

• Mixing and homogenization: ensure that all ingredients are evenly mixed and the product texture is smooth.

• Cooling and storage: quickly cool down and maintain a low temperature environment to extend the shelf life.

• Packaging and sealing: ensure that the finished product is not contaminated during the packaging process and the seal is tight.

• Finished product testing: sample and test each bottle of finished product to ensure that it meets food safety standards.

7.Flavored Milk Drinks Processing Plant Advanced Technology

In the field of flavored milk drinks processing, with the advancement of science and technology and the diversification of consumer demand, factories continue to introduce advanced technologies to improve production efficiency, product quality and safety. The following are some advanced technologies and innovations in current flavored milk drinks processing plants:

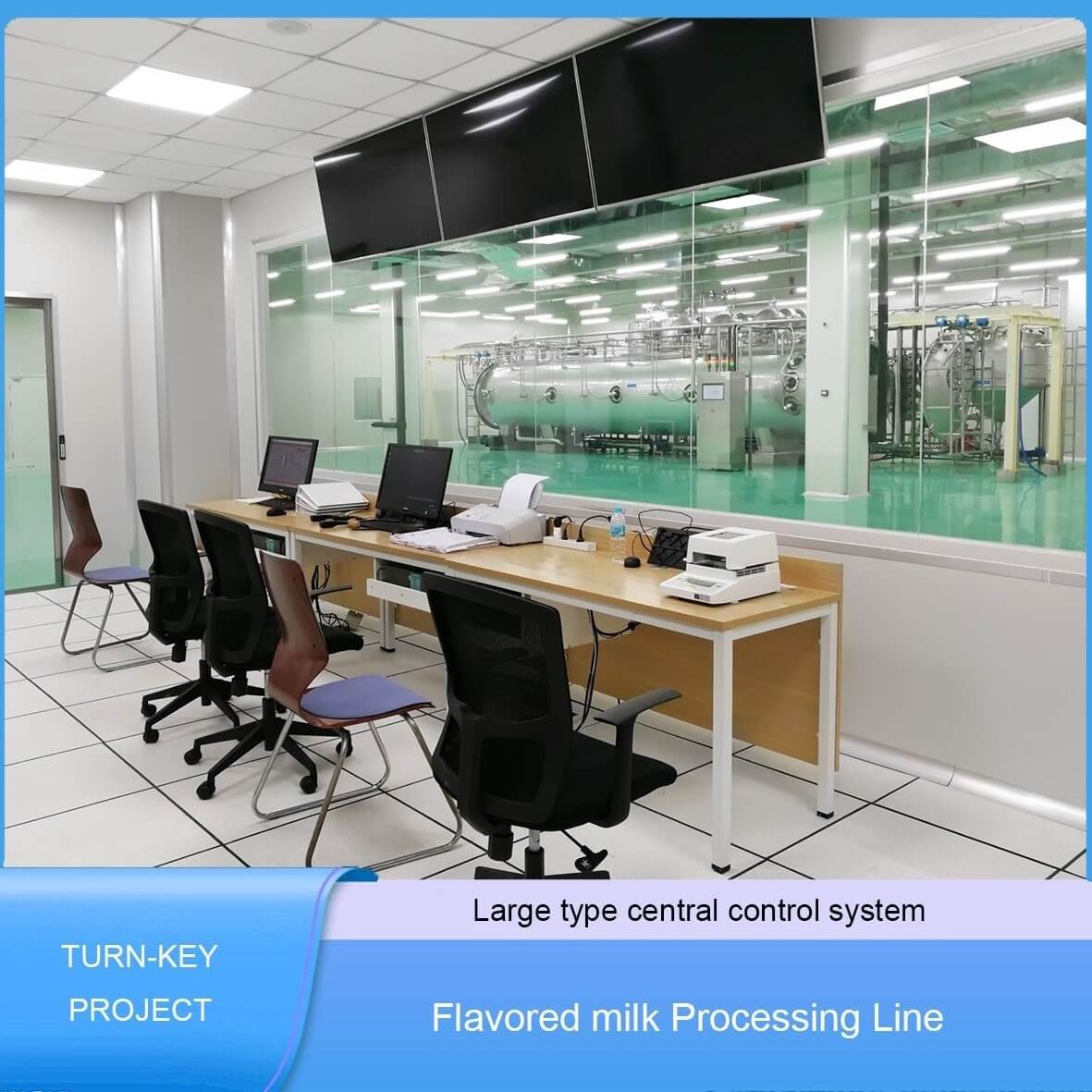

1. Automation and intelligent control system

• Intelligent production line: Through the integration of PLC (programmable logic controller) and SCADA (supervisory control and data acquisition system), the production equipment can be automatically controlled and monitored in real time. Operators can remotely manage the entire production process through the central control room.

• Robotic technology: used in packaging, handling and other links to reduce manual intervention and improve production efficiency and precision.

2. Advanced sterilization technology

• Ultra-high temperature instantaneous sterilization (UHT): Heat milk to above 135°C in a very short time, cool it quickly, effectively kill microorganisms, and maximize the retention of nutrients in milk.

• Pulsed electric field treatment (PEF): Use high-frequency pulsed electric fields to destroy the cell walls of microorganisms to achieve a sterilization effect with little impact on product quality.

• Microwave sterilization: Quickly and evenly heat the liquid, with the characteristics of high efficiency and energy saving.

3. Efficient homogenization technology

• High-pressure homogenizer: Use a high-pressure pump to pump the mixed liquid into a narrow channel, and break the fat globules into smaller particles under extremely high pressure, significantly improving the stability of the product.

• Ultrasonic homogenization: Use the cavitation effect generated by ultrasonic vibration to further refine the fat globules and enhance the smoothness of the taste.

4. Precision batching and mixing technology

• Automatic batching system: Equipped with high-precision weighing sensors to ensure that each raw material is added accurately according to the formula to avoid human errors.

• Online mixing equipment: Through dynamic mixers or static mixers, materials can be mixed instantly and evenly to shorten the production cycle.

5. Cleaning and sanitation guarantee

• CIP (cleaning in place) system: Realize fully automatic cleaning of production equipment, reduce downtime, and improve hygiene standards.

• Aseptic filling technology: Perform filling operations in an aseptic environment to prevent secondary contamination and extend the shelf life of products.

6. Green sustainable development technology

• Energy-saving and emission reduction measures: Optimize energy use, such as using heat recovery devices, solar power supply systems, etc. to reduce carbon emissions.

•Environmentally friendly packaging materials: Promote the use of degradable and recyclable packaging materials, reduce plastic waste, and respond to environmental protection calls.

7. Quality inspection and traceability system

•Online testing instruments: such as near-infrared spectrometers, X-ray detectors, etc., are used to monitor product quality parameters in real time to ensure that every bottle of product meets the standards.

•Blockchain traceability system: Record the entire process information from raw material procurement to finished product sales, improve transparency, and facilitate consumers to inquire about product sources and quality status.

8. Personalized customization platform

•Flexible production line: Support multi-variety small batch production to meet the market demand for personalized products.

•Customized service platform: Through e-commerce platforms or mobile applications, consumers are allowed to choose different flavor combinations and even participate in product design to increase interactivity and brand loyalty.

The application of these advanced technologies not only improves the modernization level of flavored milk beverage production, but also provides consumers with higher quality, safer and more personalized beverage options.

8.Flavored Milk Drinks Processing Plant Customization Process

In order to meet the diverse needs of the market and consumers' requirements for personalized products, the flavored milk beverage processing plant can provide customized services. The following are the detailed steps of the customization process:

1. Demand research and communication

• Customer demand collection: Through questionnaires, face-to-face interviews or online platforms, understand the personalized needs of customers, including taste preferences, packaging design, functional ingredients (such as probiotics, vitamins, etc.), special process requirements, etc.

• Feasibility assessment: Based on the information provided by the customer, the factory technical team conducts a preliminary assessment to confirm whether these customized needs can be achieved and gives a specific technical solution.

2. Signing a contract

• Determine the details of the cooperation: The two parties reach an agreement on product specifications, production quantity, delivery time, price terms, etc., and sign a formal cooperation agreement.

• Pay a deposit: The customer pays a certain proportion of the advance payment as agreed to start the project.

3. Product research and development

• Formula development: Professional food R&D personnel prepare suitable formulas according to customer needs to ensure the taste, nutritional value and safety of the product.

• Sample production: Small batch trial production of customized products, and make samples for customers to taste and feedback.

• Adjustment and optimization: According to customer feedback, continuously adjust the formula and production process until satisfactory results are achieved.

4. Production line preparation

• Equipment debugging: Check whether the production equipment is operating normally, and modify or upgrade it if necessary to adapt to the special requirements of new products.

• Personnel training: Provide targeted training for operators to ensure that they are familiar with new production processes and technical points.

5. Batch production

• Raw material procurement: Purchase high-quality raw materials according to the formula requirements to ensure that each batch of products meets the standards.

• Formal production: After all preparations are completed, start batch production of customized products.

• Quality monitoring: Strictly implement the HACCP management system, strengthen quality inspection during the production process, and ensure stable and reliable product quality.

6. Finished product inspection and packaging

• Factory inspection: Strict factory inspection of each batch of finished products, including sensory indicators, physical and chemical indicators, microbial indicators, etc., to ensure that the product is safe and qualified.

• Personalized packaging: According to customer needs, choose appropriate packaging materials and designs, such as bottle type, label, gift box, etc., to enhance the attractiveness of the product.

7. Logistics and distribution

• Warehouse management: Store finished products properly in a constant temperature warehouse to avoid direct sunlight and humid environment affecting product quality.

• Transportation arrangement: Arrange professional cold chain logistics vehicles for delivery according to the time and place specified by the customer to ensure that the products are delivered fresh.

8. After-sales service

• Customer support: Provide detailed instructions and technical guidance to help customers store and enjoy products correctly.

• After-sales feedback: Regularly visit customers to collect usage experience and improvement suggestions to provide reference for subsequent optimization of products and services.

Through the above customization process, the flavored milk beverage processing plant can not only meet the personalized needs of customers, but also establish long-term and stable cooperative relationships, enhance brand image and market competitiveness. If you have more specific questions or need further information, please feel free to let me know!

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of Flavored milk drinks processing plant.Please contact us now, and our professional technical engineers will customize the equipment plan for Flavored milk drinks processing plant and provide a quotation.Please contact us now to obtain the latest equipment plan and quotation.