Bone Broth Processing Line: A Comprehensive Guide to Quality and Innovation

Feb 12, 2025

Introduction to the Bone Broth Processing

Bone broth has long been celebrated for its rich flavor, nutritional benefits, and healing properties. To meet the growing demand for this versatile product, our state-of-the-art bone broth processing line offers a seamless blend of traditional craftsmanship and cutting-edge technology. Designed to produce high-quality bone broth on a large scale while maintaining the integrity and nutritional value of the ingredients, our processing line is tailored to meet the needs of modern consumers.

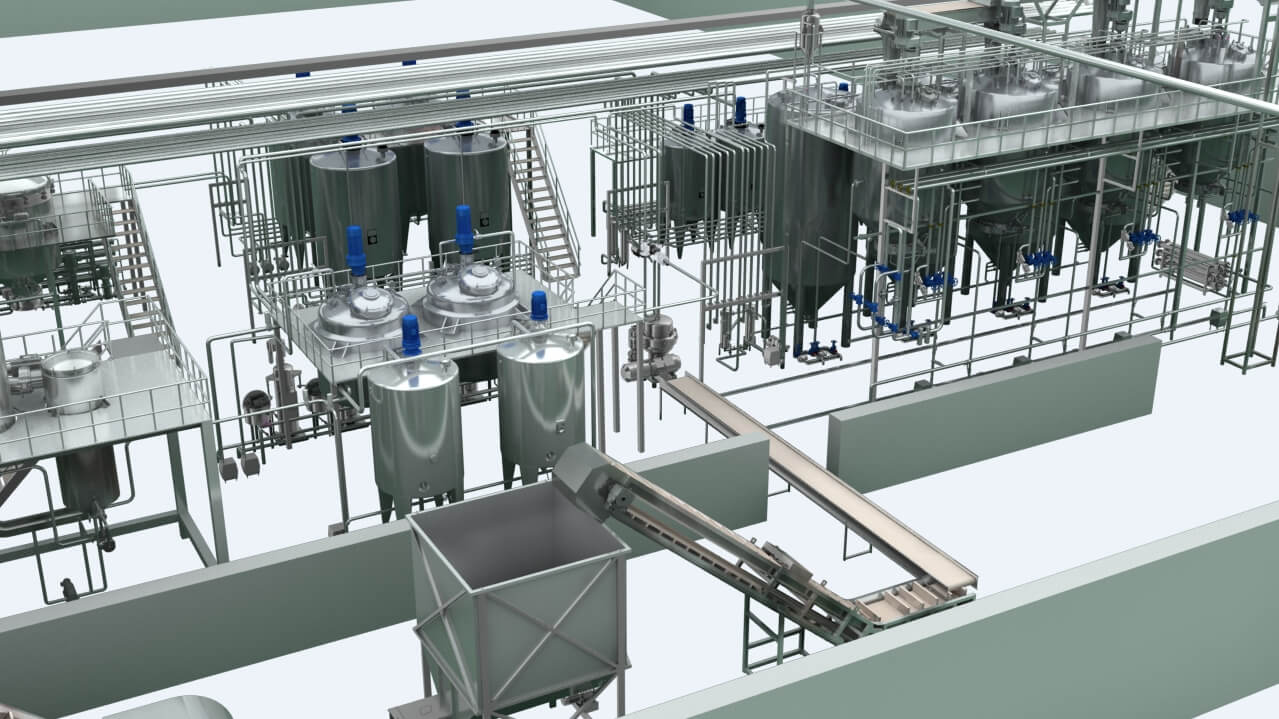

Key Equipment in the Bone Broth Processing Line

Our bone broth processing line incorporates advanced machinery that ensures efficiency, precision, and safety throughout the production process. The main equipment includes:

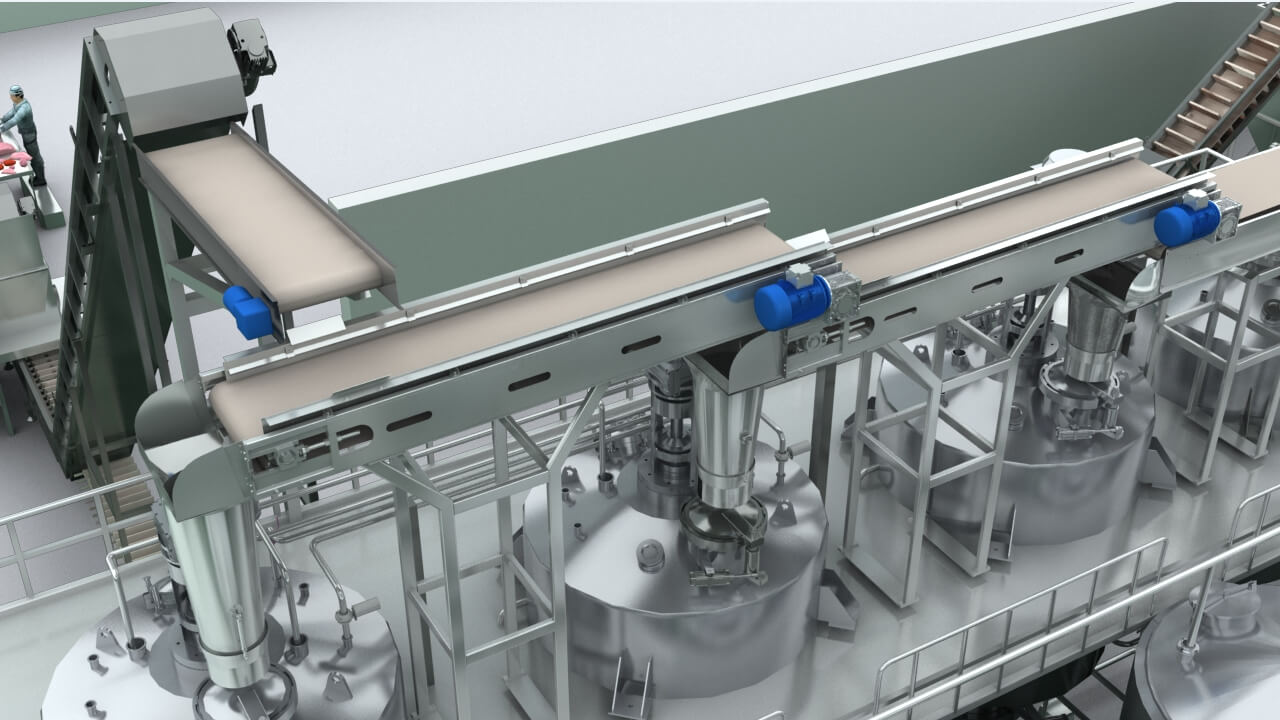

1. Preparation Station: Equipped with automated cleaning and cutting systems, this station prepares bones and vegetables for cooking.

2. Cooking Vessels: Large-capacity stainless steel tanks designed for slow-cooking at controlled temperatures to extract maximum nutrients from the bones.

3. Filtration System: Multi-stage filtration units that remove impurities while preserving essential minerals and proteins.

4. Cooling Tunnel: Rapid cooling technology to quickly lower the temperature of the broth, ensuring freshness and extending shelf life.

5. Packaging Machinery: Automated filling and sealing machines that package the broth into various formats such as bottles, pouches, or cans, depending on customer preferences.

The integration of innovative technologies in our bone broth processing line sets us apart from traditional methods:

•Automated Control Systems: Computerized controls monitor and adjust parameters like temperature, pressure, and cooking time, ensuring consistent quality across batches.

•Energy Efficiency: Optimized energy consumption through smart sensors and efficient heating elements reduces environmental impact and operating costs.

•Traceability and Safety: Advanced tracking systems ensure full traceability of raw materials and finished products, adhering to strict food safety standards.

Raw Materials and Products

We source only the finest raw materials for our bone broth, including:

•High-Quality Bones: From pasture-raised animals, providing a rich source of collagen, gelatin, and essential minerals.

•Fresh Vegetables and Herbs: Locally sourced organic produce enhances flavor and adds valuable antioxidants.

The finished products are diverse, catering to different consumer preferences:

•Classic Bone Broth: Unflavored, perfect for culinary applications.

•Flavored Varieties: Infused with herbs, spices, or vegetables for unique taste profiles.

•Functional Broths: Enhanced with additional health benefits, such as probiotics or superfoods.

Understanding that each client has unique requirements, we offer a flexible customization process:

1. Consultation: Initial discussions to understand specific needs, including flavor preferences, packaging options, and any special dietary requirements.

2. Feasibility Study: Our technical team evaluates the feasibility of the requested customizations and provides detailed recommendations.

3. Prototype Development: Small-scale production of customized samples for client approval.

4. Adjustments and Optimization: Based on feedback, adjustments are made until the desired outcome is achieved.

5. Full-Scale Production: Once the client is satisfied, the customized recipe moves into full-scale production.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of bone broth processing equipment.Please contact us now, and our professional technical engineers will customize the equipment plan for bone broth processing plant and provide a quotation.Please contact us now to obtain the latest equipment plan and quotation.

News

Hot Product