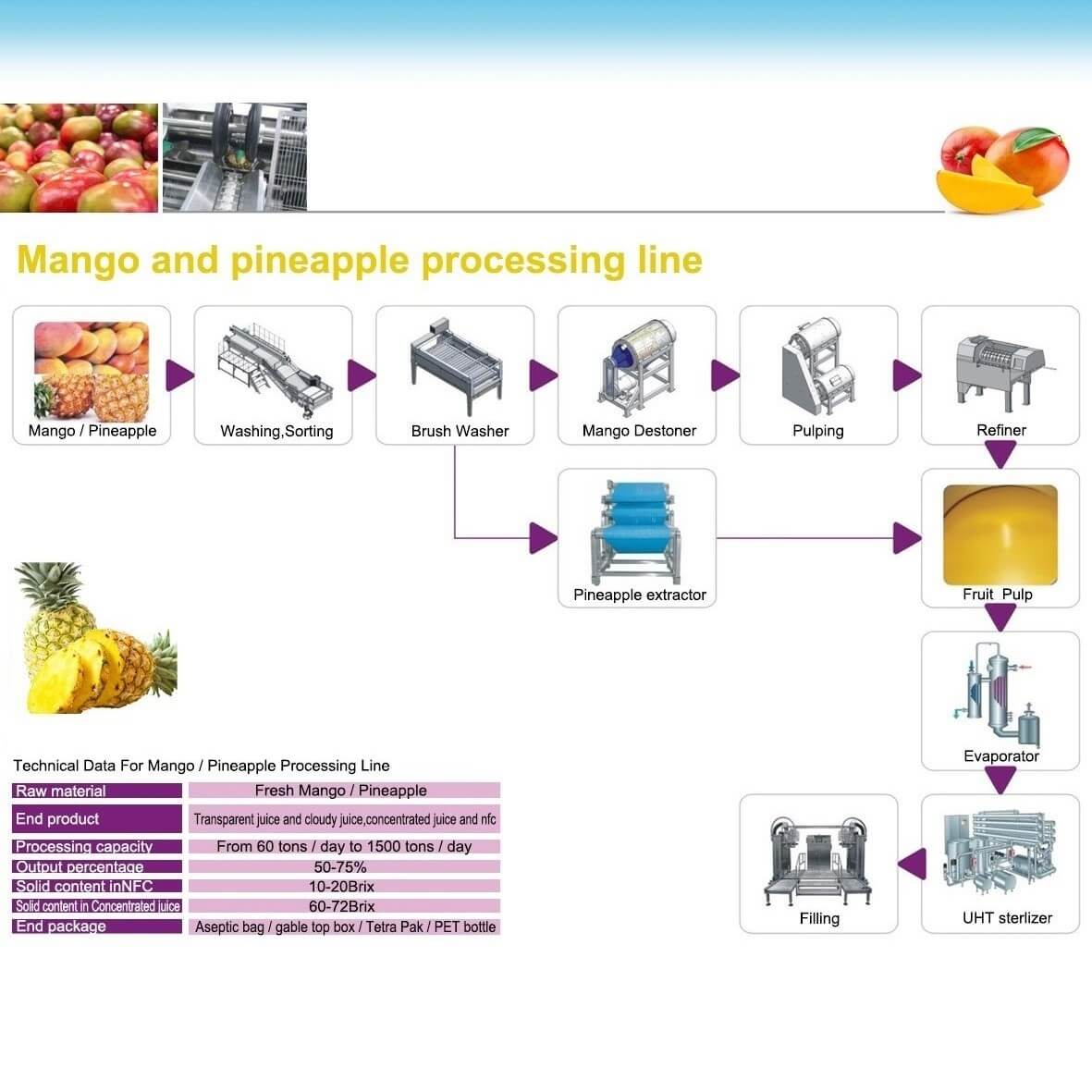

In the field of mango processing, Shanghai Beyond Machinery Co., Ltd. provides a complete set of mango juice production line equipment, which is specifically used to process fresh mangoes into juice. This production line covers the entire process from pre-processing mango raw materials to final packaging of finished products, including cleaning, sorting, peeling and pulping, preheating and enzyme activation, juice extraction, screening, mixing, homogenization, degassing, sterilization, filling and other links.

The main equipment of the mango juice production line includes:

1. Mango cleaning machine: Used to clean selected mangoes, remove impurities such as sand, soil, hair, etc., ensure the cleanliness of mango raw materials, and provide hygienic and safe food raw materials for subsequent processing.

2. Mango Peeling Machine: Using professional mango peeling equipment, it can quickly separate mango skin and core, preparing for subsequent juice extraction and increasing juice production.

3. Mango Beater: Crush mango pulp to effectively separate juice and pulp fibers, providing high-yield mango pulp for the juice extraction process.

4. Preheating and enzyme activation system: Quickly heat mango pulp to 80 ℃~85 ℃ for a short period of time to activate pectinase and prevent chemical reactions during subsequent processing and storage. This helps maintain the stability and taste of the juice, and lays the foundation for subsequent juicing and clarification processes.

5. Mango juice separator: Use a mango juice separator to separate the juice and solids in the crushed mango pulp. Through two-stage solid separation, clear or semi clear juice is obtained, making the juice purer, more transparent, and more delicate in taste.

6. Homogenization, Sterilization, and Degassing Machine: During the homogenization process, mango juice is homogenized 2-3 times under a pressure of 20-25MPa to ensure consistent particle size in the juice, prevent juice stratification and precipitation, and make the tissue uniform and viscous with a delicate taste. The sterilization process uses a high-temperature instant sterilizer to heat the juice to 120 ℃~130 ℃ for a few seconds for instant sterilization, effectively killing bacteria, mold, yeast, and other microorganisms in the juice, ensuring the microbial safety of the juice, and maximizing the preservation of the nutritional content, color, and flavor of the juice. The degassing process is mainly used to remove gas components such as oxygen from fruit juice to extend its shelf life. And it can be equipped with an aroma recovery system to maintain the color, aroma, and nutrients of mango juice during the processing to the greatest extent possible without loss.

7. Filling and packaging system: Select appropriate packaging materials and forms based on different product needs and market positioning, such as PET plastic bottles, glass bottles, Tetra Pak bags, cans, etc.

8. Advantages of Mango Juice Production Line

-Highly automated: The mango juice processing production line has achieved full process automation from mango raw material processing to finished product packaging, reducing manual intervention.

-Good hygiene conditions: The parts in contact with mangoes and fruit juice are made of food grade stainless steel, which meets the hygiene standards of food processing. The equipment is easy to clean and disinfect, effectively preventing microbial contamination and ensuring the food safety of mango juice, allowing consumers to drink with confidence.

-Energy conservation and environmental protection: Advanced design concepts and optimized process flow enable the production line to consume less energy during operation, reduce production costs, minimize environmental impact, and meet the requirements of modern enterprise sustainable development.

-Powerful flexibility: In addition to being suitable for producing mango juice, by adjusting some equipment and process parameters, it can also be used to process various fruit and vegetable juice products, such as pineapple juice, appIn the field of mango processing, Shanghai Beyond Machinery Co., Ltd. provides a complete set of mango juice production line equipment, which is specifically used to process fresh mangoes into juice. This production line covers the entire process from pre-processing mango raw materials to final packaging of finished products, including cleaning, sorting, peeling and pulping, preheating and enzyme activation, juice extraction, screening, mixing, homogenization, degassing, sterilization, filling and other links.

The main equipment of the mango juice production line includes:

1. Mango cleaning machine: Used to clean selected mangoes, remove impurities such as sand, soil, hair, etc., ensure the cleanliness of mango raw materials, and provide hygienic and safe food raw materials for subsequent processing.

2. Mango Peeling Machine: Using professional mango peeling equipment, it can quickly separate mango skin and core, preparing for subsequent juice extraction and increasing juice production.

3. Mango Beater: Crush mango pulp to effectively separate juice and pulp fibers, providing high-yield mango pulp for the juice extraction process.

4. Preheating and enzyme activation system: Quickly heat mango pulp to 80 ℃~85 ℃ for a short period of time to activate pectinase and prevent chemical reactions during subsequent processing and storage. This helps maintain the stability and taste of the juice, and lays the foundation for subsequent juicing and clarification processes.

5. Mango juice separator: Use a mango juice separator to separate the juice and solids in the crushed mango pulp. Through two-stage solid separation, clear or semi clear juice is obtained, making the juice purer, more transparent, and more delicate in taste.

6. Homogenization, Sterilization, and Degassing Machine: During the homogenization process, mango juice is homogenized 2-3 times under a pressure of 20-25MPa to ensure consistent particle size in the juice, prevent juice stratification and precipitation, and make the tissue uniform and viscous with a delicate taste. The sterilization process uses a high-temperature instant sterilizer to heat the juice to 120 ℃~130 ℃ for a few seconds for instant sterilization, effectively killing bacteria, mold, yeast, and other microorganisms in the juice, ensuring the microbial safety of the juice, and maximizing the preservation of the nutritional content, color, and flavor of the juice. The degassing process is mainly used to remove gas components such as oxygen from fruit juice to extend its shelf life. And it can be equipped with an aroma recovery system to maintain the color, aroma, and nutrients of mango juice during the processing to the greatest extent possible without loss.

7. Filling and packaging system: Select appropriate packaging materials and forms based on different product needs and market positioning, such as PET plastic bottles, glass bottles, Tetra Pak bags, cans, etc.

8. Advantages of Mango Juice Production Line

-Highly automated: The mango juice processing production line has achieved full process automation from mango raw material processing to finished product packaging, reducing manual intervention.

-Good hygiene conditions: The parts in contact with mangoes and fruit juice are made of food grade stainless steel, which meets the hygiene standards of food processing. The equipment is easy to clean and disinfect, effectively preventing microbial contamination and ensuring the food safety of mango juice, allowing consumers to drink with confidence.

-Energy conservation and environmental protection: Advanced design concepts and optimized process flow enable the production line to consume less energy during operation, reduce production costs, minimize environmental impact, and meet the requirements of modern enterprise sustainable development.

-Powerful flexibility: In addition to being suitable for producing mango juice, by adjusting some equipment and process parameters, it can also be used to process various fruit and vegetable juice products, such as pineapple juice, apple juice, orange juice, etc., achieving the multifunctionality of equipment, improving equipment utilization and investment return, and providing convenience for enterprises to expand product categories.

Application scenarios of mango juice processing

-Catering supply chain: customized production of pure mango juice for tea houses

-Supermarket Retail: Developing NFC Non Concentrated Juice Series

-Cross border trade: sterile Tetra Pak export solution that meets European and American standards

-Upgrading of Featured Products: Creating a Regional Featured Mango Deep Processing Industry Chain

Shanghai Beyond Machinery Co., Ltd. not only provides equipment, but also offers full industry chain solutions from factory planning, process design to marketing. If you want to learn more, you can leave a message anytime.