1. Land and buildings

Land acquisition: Land costs vary greatly depending on geographical location. The land prices in suburban areas of cities may range from several hundred to several thousand dollars per square meter.

Construction costs: including factory building, offices, warehouses, etc. In general, the construction cost may range from $1000 to $3000 per square meter.

2. Equipment cost

Pasteurizer: The price of a small pasteurizer may range from $10000 to $50000, while a large equipment may cost up to hundreds of thousands of dollars.

Homogenizer: The price of small homogenizers ranges from several thousand to tens of thousands of dollars, while large equipment may be more expensive.

Filters: priced between a few hundred to several thousand dollars.

Cooling system: including plate heat exchangers, priced between several thousand to tens of thousands of dollars.

Packaging machine: The price of an automatic packaging machine may range from tens of thousands of dollars to tens of thousands of dollars.

CIP cleaning system: priced between several thousand to tens of thousands of dollars.

3. Other equipment and facilities

Storage tank: used for storing raw milk and finished milk, priced between several thousand to tens of thousands of dollars.

Conveyor system: used for material transportation, priced between several thousand to tens of thousands of dollars.

Laboratory equipment: used for quality testing, priced between several thousand to tens of thousands of dollars.

4. Installation and commissioning

Installation costs: including equipment installation, pipeline laying, electrical connections, etc., generally accounting for 10% -20% of the total equipment cost.

Debugging costs: including equipment debugging, testing, and verification, generally accounting for 5% -10% of the total equipment cost.

5. License and Certification

Government licensing: Depending on regulations in different countries and regions, certain licensing fees may need to be paid.

Certification fees: Certification fees such as HACCP, ISO, etc. can range from several thousand to tens of thousands of dollars.

6. Initial operating costs

Raw material procurement: In the initial stage, a certain amount of raw milk needs to be reserved.

Employee training: Train operators to ensure proper operation of equipment.

Marketing: including brand building and marketing expenses.

7. Operating costs

Energy costs: including water, electricity, gas, and other expenses.

• Labor costs: including wages, benefits, etc.

• Maintenance costs: Regular maintenance and upkeep of equipment to ensure normal operation.

Example of Cost Estimation: Assuming you plan to establish a medium-sized milk processing plant with an annual production capacity of 5000 tons, the following is a rough cost estimate:

Land and buildings: $500000

Equipment cost: 1000000 US dollars

• Other equipment and facilities: $300000

Installation and debugging: $200000

License and Certification: $50000

• Initial operating cost: $100000

• Operating costs (first year): $500000

Total: Approximately $2650000 Notes

Market research: Conduct detailed market research to understand local market demand and competition before deciding to invest.

Financial planning: Develop a detailed financial plan, including funding sources, investment return rates, etc.

Compliance with regulations: Ensure that all operations comply with local laws and regulations to avoid unnecessary legal risks.

I hope this information can help you better plan and make decisions. If you need more detailed data or specific quotations, please contact us.

Shanghai Beyond is a professional dairy processing equipment manufacturer, providing solutions for dairy processing production lines ranging from small to large. Here are some detailed information about us:

Company Profile

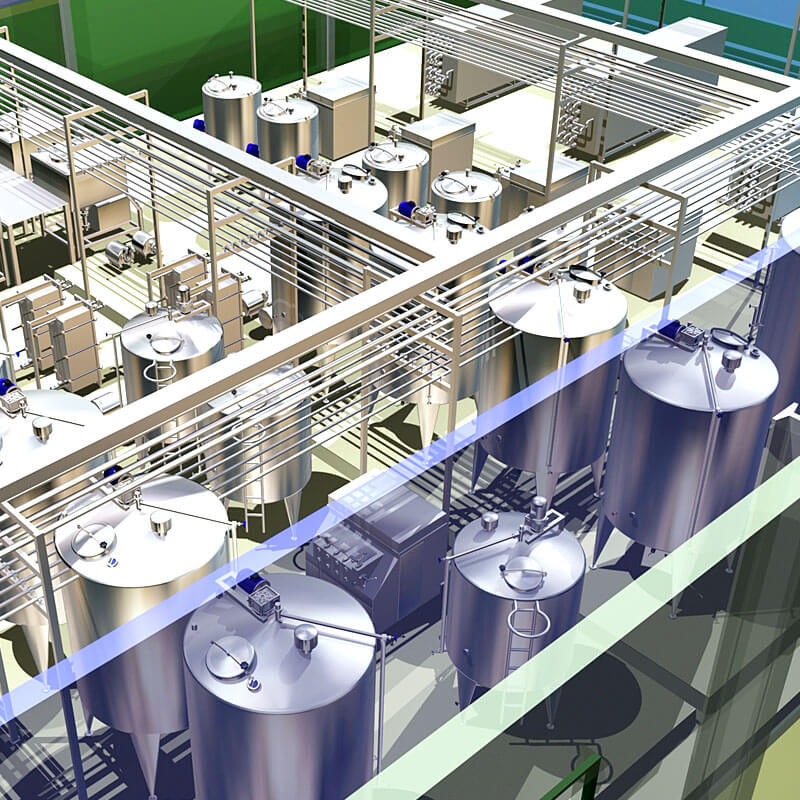

Main business: design, manufacture, and sales of dairy processing equipment, food processing equipment, and beverage processing equipment.

• Product range:

Pasteurization machine: Low temperature long time (LTLT) and high temperature short time (HTST) pasteurizers.

Homogenizer: High pressure homogenizer, suitable for the dairy and beverage industries.

Filters: Various types of filters used to remove impurities from milk.

• Cooling system: Plate heat exchangers and other cooling equipment.

Packaging machine: automatic and semi-automatic packaging machines, suitable for packaging needs of different capacities.

CIP cleaning system: a fully automatic cleaning system to ensure the hygiene and cleanliness of equipment.

advantage

Advanced technology: Adopting internationally advanced design concepts and technologies to ensure the efficiency, reliability, and safety of equipment.

Customized services: Provide personalized solutions and equipment configurations based on the specific needs of customers.

After sales service: Provide comprehensive after-sales service and technical support to ensure the normal operation of customers' equipment.

Quality assurance: Strictly implement the ISO9001 quality management system to ensure that product quality meets international standards.

Product Case

Small milk processing plants: provide complete pasteurization, homogenization, cooling, and packaging production lines, suitable for small farms and family farms.

Medium sized dairy processing plants: provide larger scale production lines suitable for medium-sized dairy enterprises and cooperatives.

Large dairy processing plants: providing comprehensive dairy processing solutions suitable for large dairy enterprises.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of milk processing plant.Please contact us now, and ourprofessional technical engineers will customize the equipment plan for milk processing plant and provide a quotation.Please contact us now to obtain the latest equipment plan and quotation.