UHT ultra-high temperature sterilized milk has a long shelf life and is suitable for trans-regional transportation and storage, but it has great damage to the active substances in milk. With the increasing demand of consumers for the taste and nutritional value of fresh milk (the content of active substances in milk), ESL extended shelf life low-temperature fresh milk, which is between pasteurized milk and UHT ultra-high temperature sterilized milk, has been popular with consumers since its launch.

ESL milk (Extended Shelf Life Milk), namely pasteurized milk with extended shelf life, is a high-quality fresh milk with high nutritional value. ESL milk not only has the fresh taste of pasteurized milk, but also has a lower number of bacteria than pasteurized milk, so its shelf life is longer than that of pasteurized milk. The apparent color, fragrance, taste and the retention of internal nutrients are very close to traditional pasteurized milk, so it is called "new generation pasteurized milk". At the same time, ESL milk overcomes the defects in taste and texture of UHT milk, including oxidized stale taste, separation of cream and fat, formation of gel or precipitation, etc. The shelf life of ESL dairy products is generally set between pasteurized milk and UHT milk, and its shelf life is at least 15 days and up to 45 days under cold storage conditions.

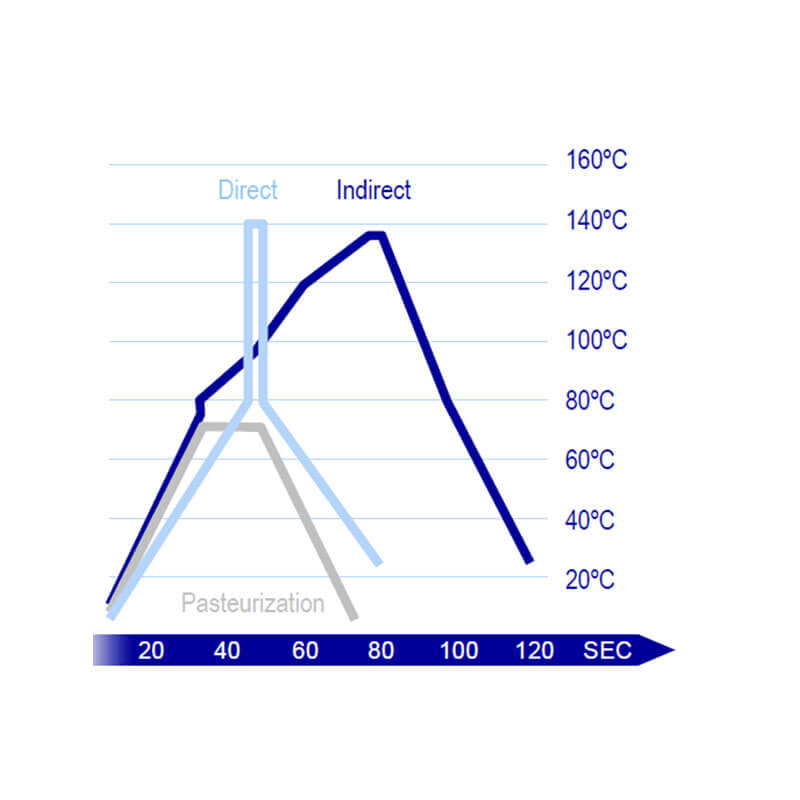

Direct or indirect?

Direct heating UHT

Heating method: steam injection or immersionFeatures: instantaneous heating and cooling

Advantages: small chemical change of products

Adverse effect: slightly higher operating costs

Indirect heating

Heating method: tubular or plate heat exchanger

Features: slow heating and cooling

Adverse effect: slightly higher product chemistry

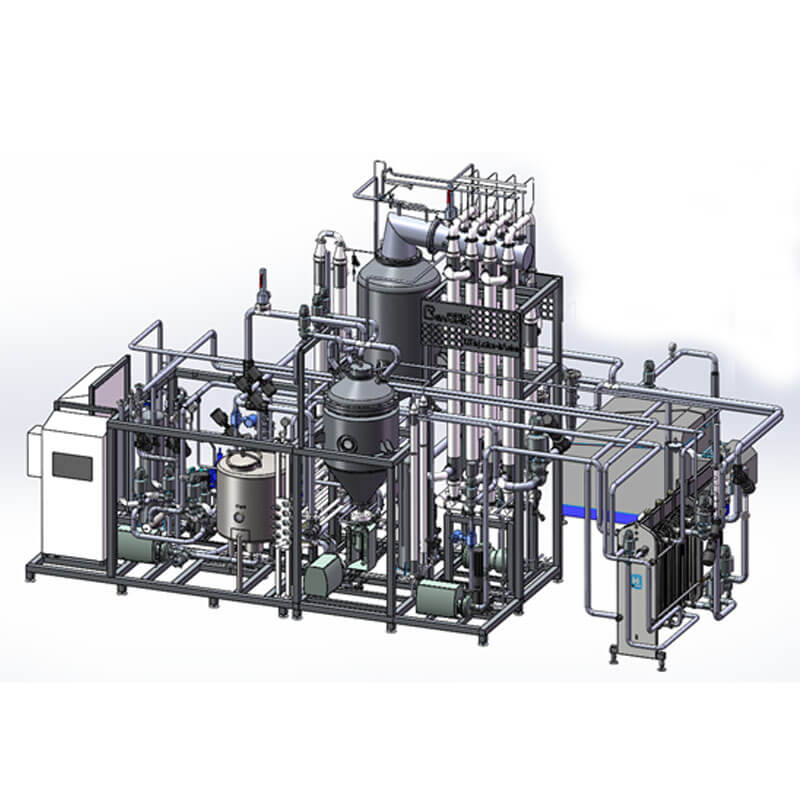

Direct UHT-treatment

Direct heating UHT treatment

► Direct heating and cooling reduce product chemical changes

► Low nutrition loss

► Quality of high-end products

► Two heating methods:

− Steam injection

− Steam infusion

► Suitable for white milk to high viscosity ice cream

► Capacity from 2000 – 30000 l/h

Typical sterilization process

► 1. Low-temperature products (INF low-temperature fresh milk):

143-158 ℃ sterilization → 0.09S insulation → flash → 65 ℃ homogenization → 1-4 ℃ discharge

► 2. Normal temperature products (cream, coconut milk):

135-142 ℃ sterilization → 4/6S insulation → flash → 82 ℃ homogenization → 10-25 ℃ discharge

► 2. Heat sensitive products (oatmeal):

115-140 ℃ sterilization → 5/10/15/30/60S insulation → flash → 85 ℃ → 60-70 ℃ discharge

Product performance comparison: take the sterilization temperature of 143 ℃ as an example, because the steam temperature in the tank is less than 144 ℃ during heating, the heating time of the immersion UHT is shorter; Injection steam direct-injection UHT partial materials are as high as 165 ℃, and the heating time is a little longer. The superheat degree and heating time of the materials are lower than that of the direct-injection type, so the immersion type has less damage to the nutrient composition and flavor of the materials.

The cost of Infusion steam immersion UHT is also higher than that of injection steam direct injection UHT due to the need to configure heating chamber, relevant pipe valves, centrifugal pump, jacket cooling system, etc

Steam injection +Steam infusion

Steam injection+steam immersion

Spray sterilization and immersion sterilization can be integrated into one system, and the production selection is more flexible. The production process can be easily switched through the adapter plate to adapt to different heat treatment requirements

General homogenization pressure of sterile homogenizer

It is 60MPa and needs to be equipped with sterile cooling water system

Principle of sterile water system:

By sterilizing pure water at high temperature, and then cooling

After-supply sterile homogenizer

1. Direct heating UHT: Due to the rapid temperature rise of materials and steam directly mixed, and the rapid temperature drop of flash after heat preservation, the heating time of dairy products is greatly shortened, and the loss of active nutrients and flavor is very small, almost comparable to pasteurized milk;

2. The ultra-high temperature method improves the sterilization efficiency and greatly extends the shelf life, which is beneficial to the dairy enterprises to expand the sales radius and increase the market share;

3. Direct heating UHT is not only used for low-temperature fresh milk, but also for high heat-sensitive products. Some products can not accept long-term heating of traditional sterilizer, so direct heating UHT can be used;

4. Compared with immersion and injection, fusion has advantages in preserving the nutrition and flavor of the product, but the cost is higher. Customers need to consider the choice comprehensively.