Stainless steel silo is a device used for storing materials, usually made of stainless steel material. It has the characteristics of corrosion resistance, rust prevention, and good sealing, and is suitable for storing various powdered, granular, or liquid materials.

The stainless steel silo is mainly composed of a cylinder, inlet and outlet ports, exhaust ports, mixing devices, sensors, etc. The cylinder body is generally made of stainless steel plates, which have high strength and corrosion resistance. The inlet and outlet are used for material loading and unloading, while the exhaust port is used to regulate internal air pressure. The mixing device can help to evenly mix materials, while the sensor is used to monitor parameters such as material level and temperature inside the silo.

Stainless steel silos are widely used in industries such as food, chemical, pharmaceutical, and metallurgy. They can store different types of materials such as grains, powders, particles, liquids, etc. The use of stainless steel materials ensures the safety and hygiene of stored materials, while also facilitating cleaning and maintenance.

When using stainless steel silos, the following points should be noted:

2. When loading and unloading materials, attention should be paid to operating standards to avoid material accumulation that is too high or too low, so as not to affect the normal operation of the silo.

3. Regularly inspect and maintain the silo to ensure good sealing performance and prevent material leakage or contamination.

4. Select appropriate mixing devices and sensors based on the characteristics of the material to improve its uniformity and monitoring accuracy.

In summary, stainless steel silos are reliable, durable, and suitable for storing various materials, playing an important role in industrial production.

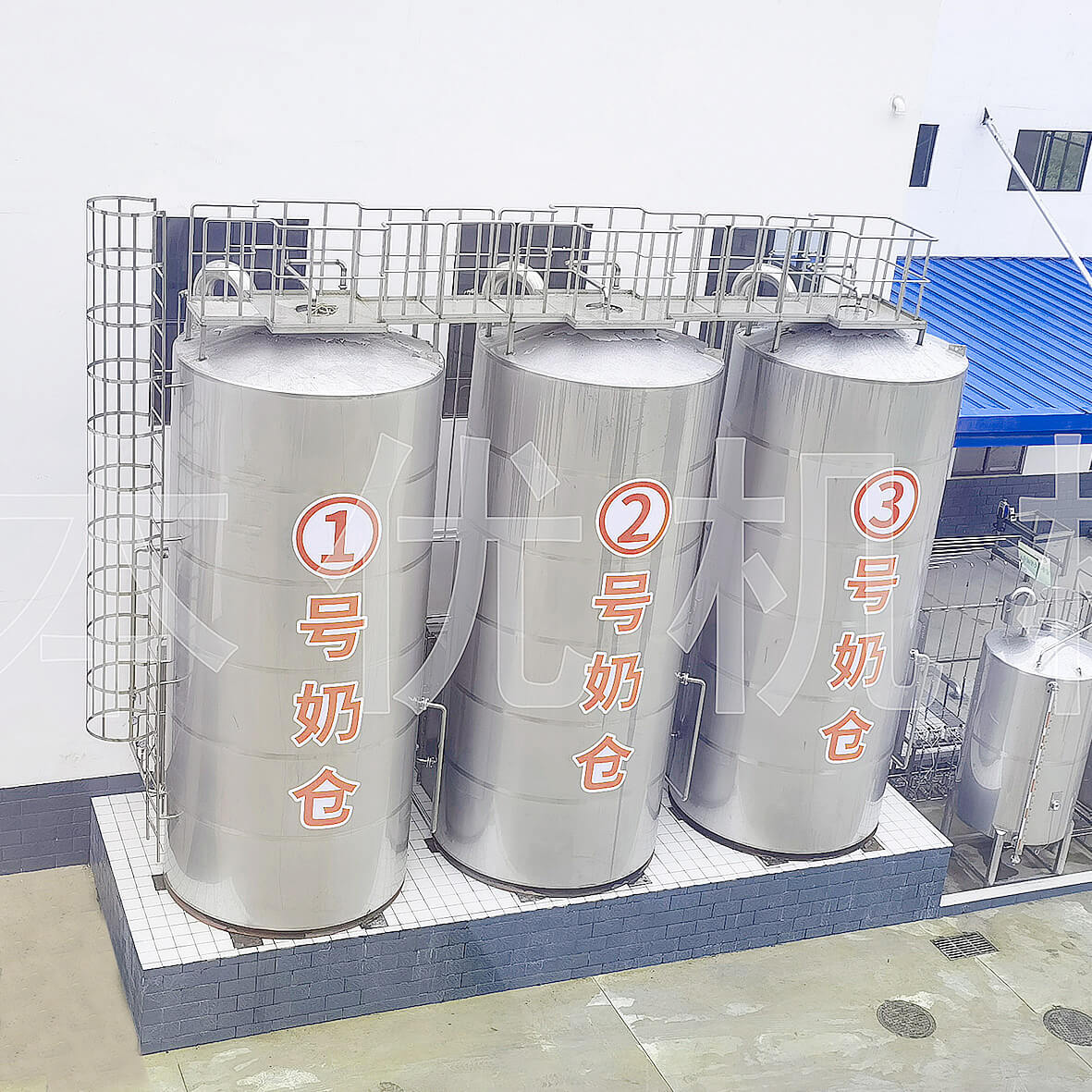

A milk silo tanks refers to a facility or place used to store milk or other dairy products. In the production and supply chain of dairy products, milk silo tanks play an important role in ensuring the quality and safety of dairy products.

Milk silo tanks typically have the following functions and characteristics:

1. Temperature control: The milk warehouse needs to maintain a suitable temperature to ensure the freshness and quality of dairy products. Generally speaking, the storage temperature of milk should be maintained between 2-4 degrees Celsius.

2. Hygiene conditions: The milk warehouse must comply with hygiene standards to prevent the invasion of bacteria and other pollutants. Regular cleaning and disinfection are necessary operations.

3. Storage capacity: Milk silos need sufficient storage capacity to meet the needs of dairy producers of different sizes and demands.

4. Packaging and labeling: The milk warehouse should provide appropriate packaging and labeling facilities to ensure product traceability and accuracy of information.

5. Logistics management: The milk warehouse needs to carry out logistics management, including the process of receiving, storing, sorting, and distributing dairy products. This requires an effective inventory management system and transportation arrangements.

6. Safety measures: The milk silo tanks should take necessary safety measures to prevent fires, and other accidents from occurring.

The design and operation of a dairy silo tanks need to take into account the characteristics and needs of dairy products, as well as the requirements of relevant regulations and standards. In China, the dairy industry is an important industry, and the construction and management of milk warehouses are crucial for ensuring the quality and supply stability of dairy products.

Stainless steel milk silo is a device used for storing and processing milk, which adopts advanced technologies to ensure the quality and safety of milk. Here are some common advanced technologies:

1. Temperature control: Stainless steel milk silos are usually equipped with advanced temperature control systems, which can accurately control the temperature inside the milk silo. This is crucial for maintaining the freshness of milk and preventing bacterial growth.

2. Automation system: Modern stainless steel milk silos are usually equipped with automation systems, which can monitor and control various parameters inside the milk silo, such as temperature, humidity, pressure, etc. These systems can improve production efficiency and ensure the quality and safety of milk.

3. CIP cleaning system: CIP (Clean in Place) is an automated cleaning system that can thoroughly clean and disinfect milk silos without disassembling equipment. This system can reduce manual operations and ensure the hygiene and safety of the milk warehouse.

4. Internet of Things technology: Some advanced stainless steel milk silos also apply Internet of Things technology, which enables remote monitoring and management of milk silos through sensors and internet connections. This can improve the visualization and traceability of the production process, and promptly identify and solve potential problems.

5. Ultrafiltration technology: Ultrafiltration is a separation technology that can separate substances such as fat and protein from milk through a filtration membrane, thereby obtaining a purer whey. The ultrafiltration technology in stainless steel milk silos can improve the quality and nutritional value of products.

6. Modified Atmosphere Technology: Modified Atmosphere Technology is a technology that controls the composition and concentration of gases, which can extend the shelf life of milk. By adjusting the oxygen and carbon dioxide content in the milk warehouse, bacterial growth and oxidation reactions can be slowed down, maintaining the freshness and taste of the milk.

The application of these advanced technologies enables stainless steel milk silos to better meet the needs of the milk processing industry, improve production efficiency, and ensure product quality and safety.

Shanghai Beyond Machinery Co., Ltd

Beyond Machinery specializes in the design and manufacturing of milk silo tanks. Please contact us now, and our professional technical engineers will customize the equipment plan for milk silo tanks and provide a quotation. Please contact us now to obtain the latest equipment plan and quotation.