Advantages of plate sterilizer: The plate sterilizer is composed of multiple detachable plate heat exchangers connected in series, which has high heat exchange efficiency; The plate sterilizer has a small temperature difference between the product and the heating medium in the heating section, and the heating time of the product is short, so it is especially suitable for heat-sensitive products, such as protein drinks, soybean milk, dairy products, fruit juices, etc.; The plate sterilizer occupies a small area, and the heat recovery rate can be as high as more than 90%, which greatly reduces energy consumption and significantly reduces operating costs;

Technical features

1. During the heating up phase of SIP or CIP, the product pipeline bypass butterfly valve is opened, which greatly speeds up the heating up speed (saving the heating up time by more than 50%);

2. The pressure on the product side is always higher than the pressure on the medium side to prevent pollution caused by medium leakage;

3. The balance barrel is equipped with a lower barrel, which minimizes the mixing of product and water during the medium switching process, thereby reducing the product loss rate;

4. Good man-machine interface, formula management of various processes, one-button start, reducing human error;

5. The temperature curve tracks and records key control points in real time, with good traceability;

Critical control point

1. The sterilization temperature is precisely controlled, with an accuracy of ±0.3°C;

2. The sterilization temperature is strictly controlled. When the sterilization temperature is lower than the set lower limit, the timer will stop timing and reset to strictly ensure the sterilization effect of the equipment;

3. Intelligent PID adjustment to meet the smooth transition during process switching and reduce temperature fluctuations;

4. The temperature after heat preservation is automatically compared with the sterilization temperature in real time to eliminate measurement errors;

5. The entrance and exit detection port of the heat preservation section is close to the plate, and the heat preservation time measurement is more accurate;

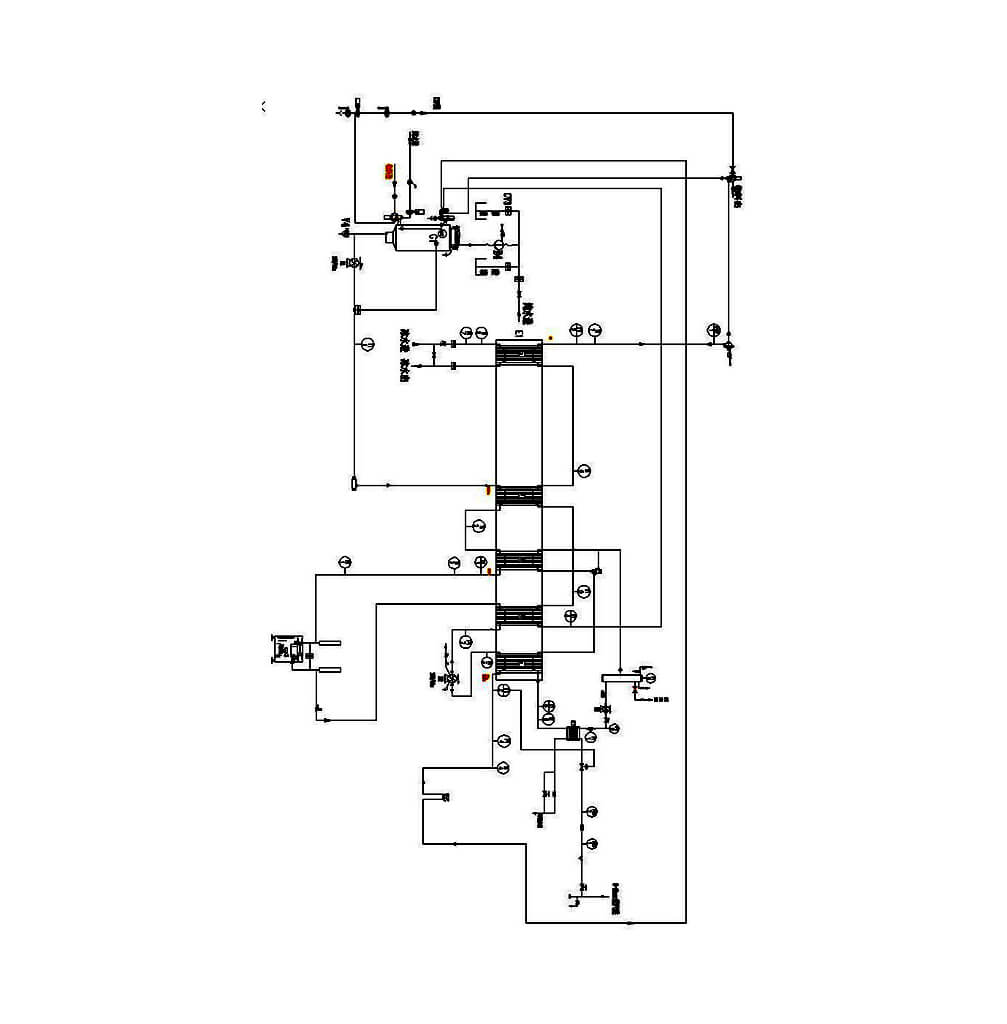

Process drawing case

Process description:

The product is pumped into the product balance tank from the previous process, and then sent into the sterilization section by the product pump. The product enters the homogenizer (25MPa) when reaches a homogenization temperature of 60-65°C; After homogenization, the product is heated to 85/115°C and held for 15 seconds for constant temperature sterilization. After heat recovery and ice water cooling, the temperature of the product is controlled at 4°C and sent out.

The sterilization temperature is controlled by the steam regulating valve according to the perception of the sterilization temperature by the temperature sensor, and the signal is fed back to the temperature control instrument to automatically control the opening of the valve so that it meets the requirements of the sterilization temperature. If the sterilization temperature does not meet the requirements, the pneumatic reversing valve installed at the discharge port will automatically reverse the flow to the product balance tank, and re-enter the sterilizer for sterilization.