The sweetened concentrated milk production line of the condensed milk factory can produce a large amount of sweet condensed milk. Condensed milk is a kind of concentrated milk, in which sugar is added as a preservative. It is different from unsweetened evaporated milk, which is stored by high-temperature sterilization after packaging. Generally, condensed milk contains about 8% fat, 45% sugar and 20% non fat solids. The finished products are mainly used in the manufacture of candy and chocolate.

Traditionally, condensed milk is produced by adding sugar to whole milk and removing water by evaporation. More and more condensed milk is made by adding skimmed milk powder, yellow oil and sugar to milk or water to increase the solids to the required level. Depending on the amount added, this can shorten or even eliminate the evaporation phase.

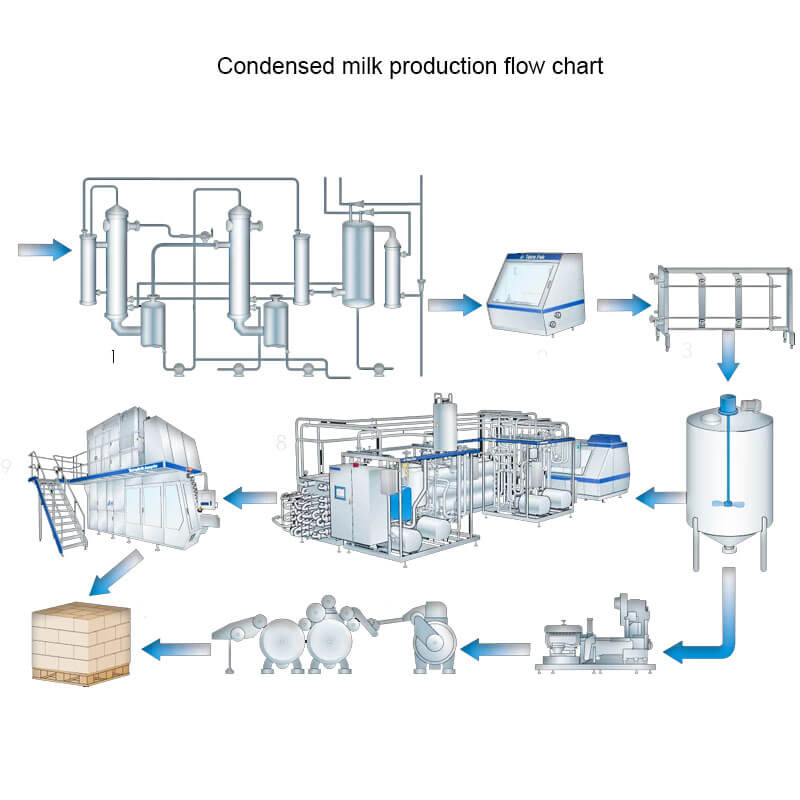

Whole milk -->reconstituted concentrated milk -->homogeneous -->pasteurized -->crystalline -->packaging

Skim milk powder and whole milk powder have strong cohesion and are difficult to wet, which makes it difficult to handle and control the addition of milk powder.

When the powder is added to the liquid, agglomerates are formed. The agitator cannot generate enough shear force to rapidly decompose these particles.

It is a slow process to use a blender to dissolve high concentrations of sugar.

High pressure homogenization may be required to ensure that the product is free of aggregates and properly dispersed.

Solutions for Milk Refinery

These problems can be solved by using the mixer. In most cases, sugar will be added directly to the container and dispersed through a batch mixer or a simple mixer used in conjunction with an online mixer. The high shear action of the rotor/stator working head accelerates the dissolution process. Milk powder can be added in the same way or, if the amount is large, a powder/liquid mixing system can be used.

These advantages are due to the three-stage mixing/shearing action generated by the rotor/stator working head, which operates as follows:

Phase 1

The high-speed rotation of the rotor blades creates a strong suction force, which draws milk and sugar particles/milk powder from the container into the working head.

Phase 2

The centrifugal force drives the material to the periphery of the working head, where the material is milled in the gap between the rotor and the stator wall. When the milk powder is finely dispersed into the milk, the aggregates in the milk powder are decomposed.

Stage 3

When the new material enters the working head, the product is pushed out through the stator. In a short mixing cycle, all materials pass through the working head, gradually reducing the size of sugar particles, increasing the surface area of milk, and accelerating the dissolution process.

Non agglomerated dispersion of milk powder.

The improved premixing quality reduces the homogenization time and eliminates the need for high-pressure homogenization.

The mixing time is greatly shortened.

The evaporation phase can be eliminated by high concentration solids achieved by high shear mixing.

The combination of particle size reduction and severe mixing greatly accelerated the dissolution of sugar.

High shear batch mixer

Can be used to move the floor stand

It is easy to move from one ship to another

High shear online mixer

Suitable for mass production

Easy to retrofit to existing plants

Must be used with an effective in tank agitator to wet the powder

No aeration

Self pumping

Can be used for container discharge

Suitable for mass production

Can quickly add a large amount of milk powder

Then add the sugar directly into the container. The dissolution process is accelerated by recirculation through the on-line mixer

Minimize aeration

Minimize cleaning requirements

Controlled powder addition rate

Minimum operator input required

Suitable for high viscosity mixtures

Suitable for operation at higher temperatures