If you're looking to set up a UHT milk production facility or simply want to understand more about the technology behind UHT processing, it's important to consider factors such as the type of milk being processed (whole, skimmed, flavored, etc.), the desired shelf life, and the target market's preferences.

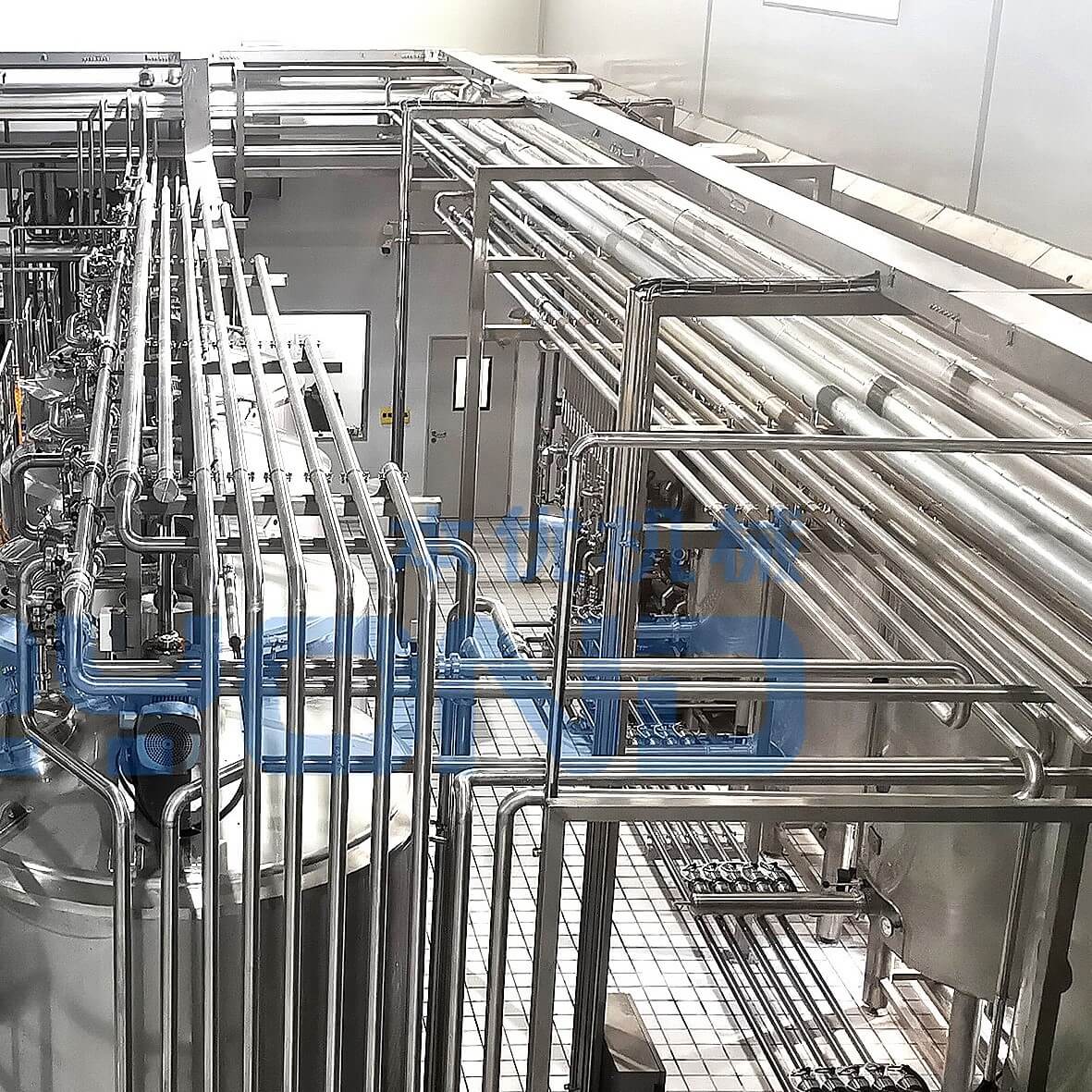

Would you like to know more about the technical specifications of UHT machines, the cost implications of setting up a UHT processing line, or any other aspects of UHT milk production? I'm here to help with all your inquiries!Here's an illustration depicting a UHT milk production line, showcasing the sterilization, homogenization, and packaging processes.

1.Homogenization: This breaks down fat globules to ensure a smooth texture.

2. Pasteurization/UHT Sterilization: The milk is heated to very high temperatures to eliminate pathogens and spoilage microorganisms.

3. Cooling: After sterilization, the milk is rapidly cooled to prevent recontamination.

4. Aseptic Filling and Packaging: The cooled milk is then filled into sterilized containers using aseptic techniques to prevent bacterial entry.

Each step in the process is critical for maintaining the safety and quality of the final product. UHT milk production lines are designed to handle large volumes efficiently while adhering to stringent hygiene and safety standards.

A UHT (Ultra High Temperature) milk production machine is designed to process milk through a series of steps that culminate in Ultra High Temperature treatment. This process extends the shelf life of milk without refrigeration, making it ideal for distribution over long distances and in areas where refrigeration might not be readily available.

Here's a breakdown of the typical steps involved in UHT milk processing:

1. Pre-treatment: Milk is first pre-treated, which includes standardization (to adjust fat content), homogenization (to break down fat globules for a smoother texture), and pasteurization (to kill off harmful bacteria).

2. UHT Processing: The pre-treated milk is heated to a very high temperature, usually around 135°C to 150°C, for a few seconds. This kills most bacteria and spores, ensuring a long shelf life.

3. Cooling: Immediately after UHT treatment, the milk is rapidly cooled back down to around 10°C to prevent re-contamination and maintain quality.

4. Packaging: UHT milk is then aseptically packaged, which means the milk and the packaging material are both sterilized before they come into contact with each other. This ensures that no bacteria can enter the package during the filling process.

5. Storage and Distribution: Once packaged, UHT milk can be stored at room temperature without spoiling for months, provided the packaging remains unopened.

Milk production machine

A milk production machine is an industrial equipment used in the dairy industry for processing raw milk into various dairy products.

These machines can handle different stages of milk production, including:

1. Milk Collection and Cooling Tanks: Used to collect fresh milk from cows and quickly cool it down to preserve freshness.

2. Pasteurizers: Heat the milk to a specific temperature to kill harmful bacteria while preserving the nutritional value and flavor of the milk.

3. Homogenizers: Break down fat globules in milk to prevent cream from separating out, ensuring a consistent texture.

4. Packaging Machines: Fill and seal containers with processed milk, ready for distribution.

5. UHT (Ultra High Temperature) Processing Plants: Heat milk to ultra-high temperatures for extended shelf life without refrigeration.

6. Cream Separators: Separate cream from milk to produce products like butter and cream.

7. Cheese Making Equipment: Used to make various types of cheese by coagulating milk proteins.

8. Yogurt Production Lines: Ferment milk to produce yogurt with added cultures.

9. Powdering Machines: Convert liquid milk into powdered form for easier storage and transportation.These machines are designed to operate efficiently and hygienically, adhering to food safety standards to ensure the quality and safety of dairy products.

If you have any further questions about the specifics of UHT milk production, the types of machinery used, or considerations for setting up a production facility, feel free to ask! I'm here to provide you with detailed information and support.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of milk production machine.Please contact us now, and our professional technical engineers will customize the equipment plan for milk production machine and provide a quotation. Please contact us now to obtain the latest equipment plan and quotation.