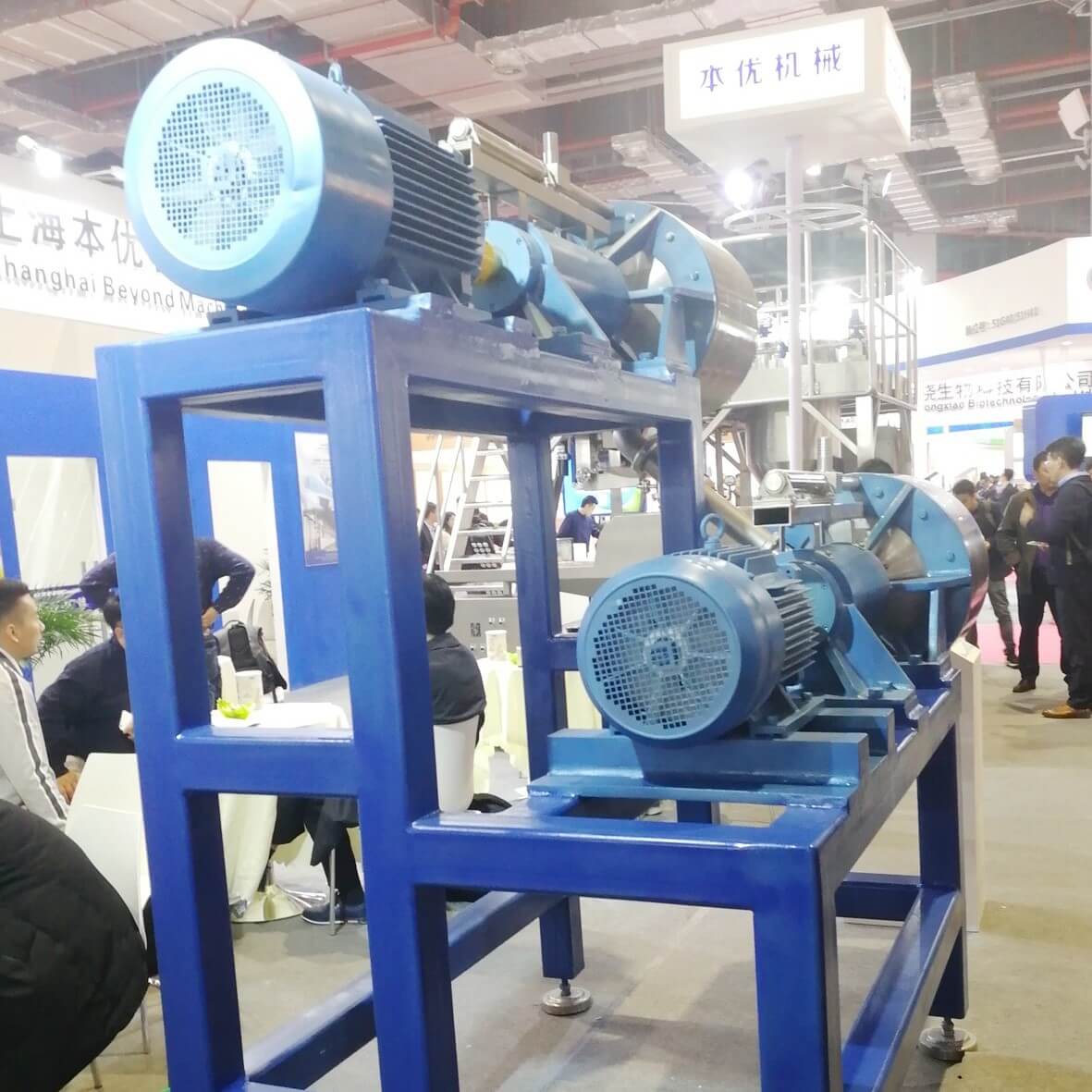

The high-speed double stage Pulping Machine produced by Beyond machinery is developed by introducing foreign advanced technology. It is mainly used for beating berries, tomatoes and other raw materials to separate pulp, fruit juice and other parts, so as to facilitate the concentration of fruit juice and the completion of other subsequent processes.

Equipment introduction and optimization

The equipment has the advantages of reasonable structure, high efficiency, high pulp yield, fast separation speed, large production capacity and good stability.

Scope of application: tomato, kiwi fruit, strawberry, apple, pear after crushing, hawthorn and jujube after pre boiling and softening, etc.

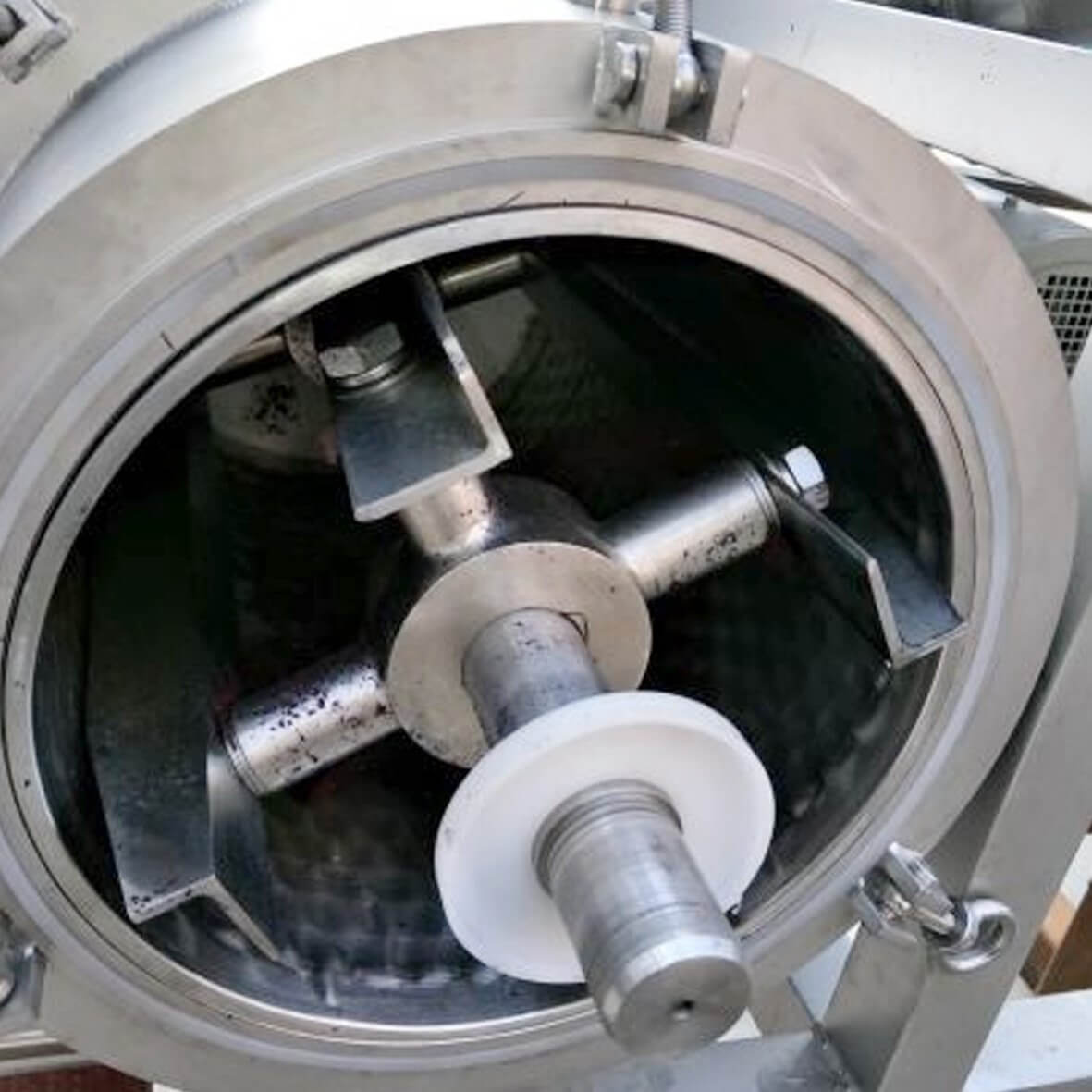

Working principle: the materials from the previous process enter a material barrel, the main shaft drives the impeller to rotate at high speed, and the materials are driven by the impeller to rub and squeeze with the screen, so that the meat and juice of the materials are separated from the skin and seeds. The meat and juice enter the material barrel through the small hole on the screen, and the skin and slag are pushed to one end and discharged through the slag discharge port. After beating, it can be cleaned automatically.

3. Equipment optimization

Compared with the old equipment, the beating screen components and impeller components are optimized. Due to the taper direction of the original structure (the large end diameter of the impeller and the small end diameter of the screen), the assembly and disassembly are more cumbersome. It is difficult to replace the screen by dismantling the impeller. In actual production, it will cause serious waste of labor cost and time cost.

Optimization: due to different batches and types of materials, screens with different apertures often need to be replaced in actual production. For different types of materials, it is particularly important to adjust the gap between the beating plate and the screen. Therefore, the structure of convenient disassembly and assembly of the screen and adjustment of the gap can greatly save production time and cost and meet the diversified requirements of customer production. The lightweight design of the movable cover greatly facilitates the difficulty of assembly and disassembly and improves the safety of operation.

So far, the optimization introduction of high-speed double channel beater is over. After optimization and improvement, this product has achieved good operation stability and convenience. If you have any questions, please contact the excellent service engineer.