What is “CIP”?

Cleaning In Place, “CIP” for short, also known as in site cleaning, this system can use professional cleaning agent to clean the equipment strongly without any break up, it can clean the dirt and also the microorganism will be killed at the same time. This system has been widely used in food and beverage factories with high degree of mechanization including, beverage, dairy, juice, pulp, jam and wine.

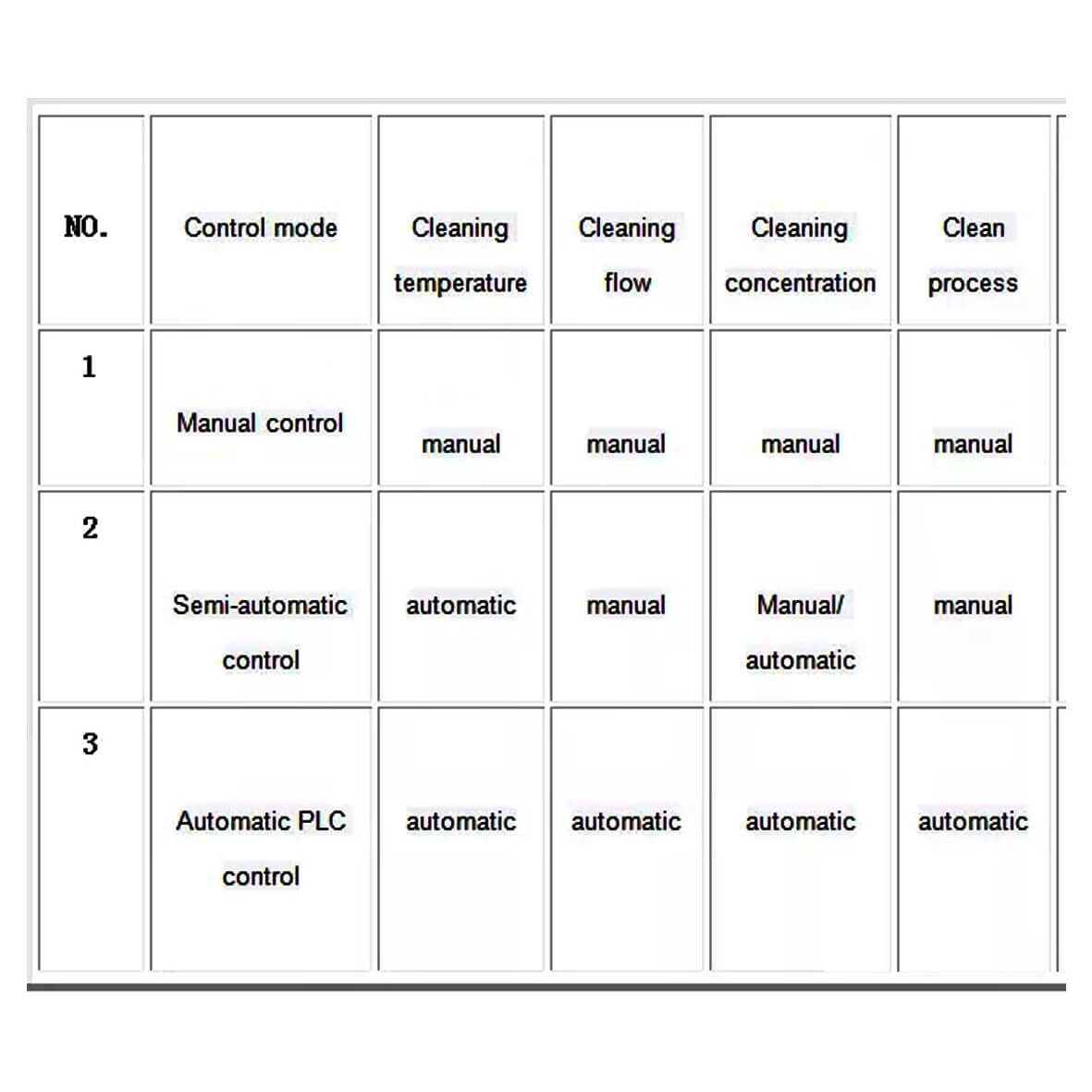

According to the operation control mode can have thefollowing general classification.

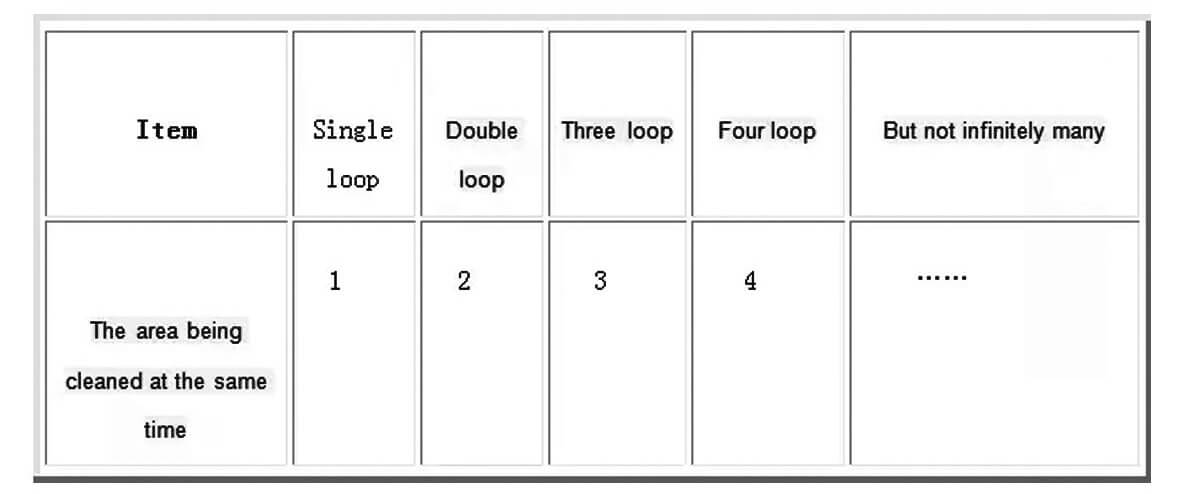

According to the quantity of areas that can be cleaned at the same time, we will have following classification:

According to the quantity of areas that can be cleaned at the same time, we will have following classification:

Important components

A complete full auto CIP system is mainly composed of the following parts:

Cleaning liquid storage tanks, adding system, forwarding pump, heating module, control valve, automatic control instrument, PLC automatic control system, etc.

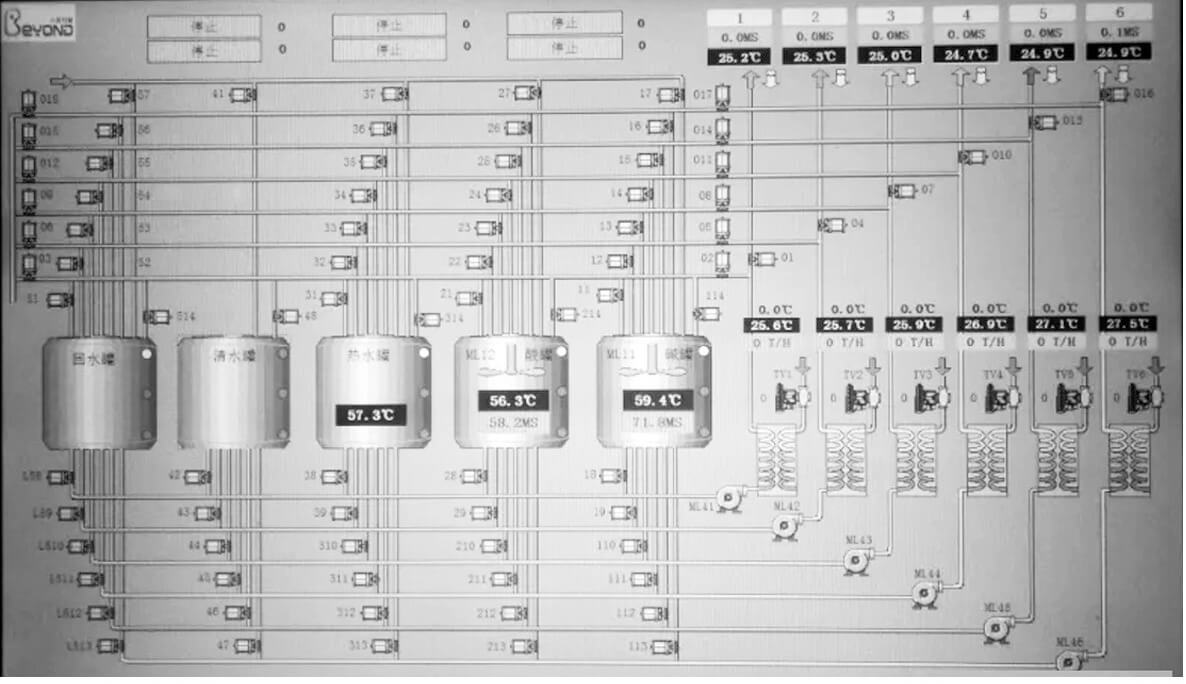

Following is a set of five-tank and six-loop automatic CIP control system designed by our company. Compared with the commonly used four-tank system (acid tank, alkali tank, hot water tank, clean water tank), a cleaning liquid recovery tank is added which will be used to recover low concentration of cleaning liquid, more than 30% of water will be saved.

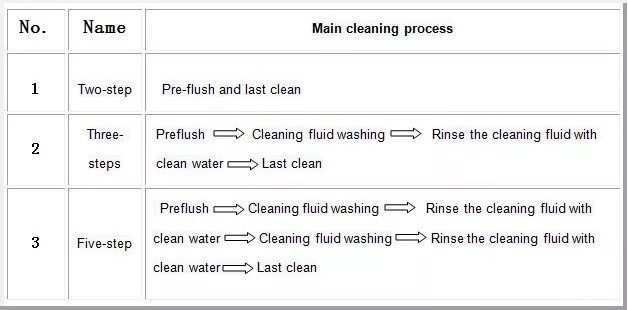

The system has the following process characteristics

-

Full-automatic PLC programming control, humanized operation mode.

- With color touch screen to display the entire production process and control parameters

-

Cleaning flow variable can be identified and controlled

-

Cleaning temperature variable can be automatic controlled

-

Automatic control of cleaning concentration

-

Automatic cleaning time control (formulation management)

-

Automatic cleaning level control

- Automatic switching of cleaning process

-

Automatic alarm and record of cleaning failure

-

Authorized discharge of cleaning fluid

-

Self-neutralization function for cleaning fluid discharge

-

Safe addition control of strong acid and alkali

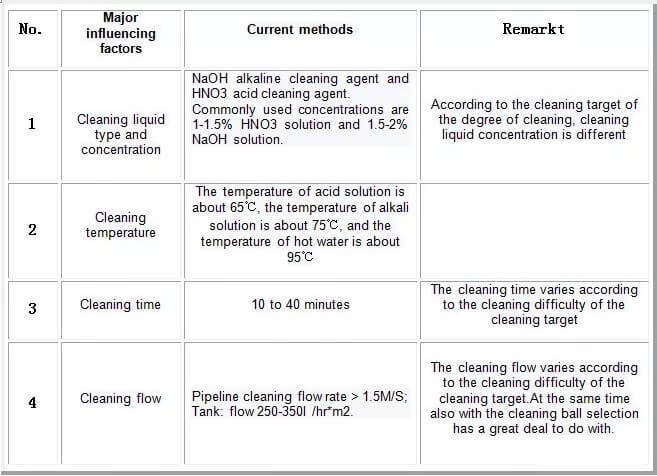

Influence factors

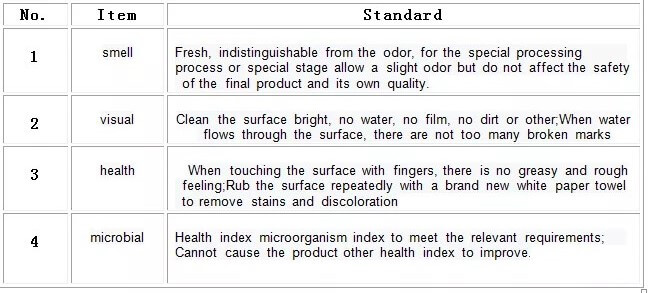

Validation criteria

CIP cleaning must meet the following criteria:

That is all we talked about CIP system today. If you have any questions, please contact our service engineer!