High-Pressure Processing: The Cold Revolution Redefining Food Safety and Shelf Life

Sep 5, 2025

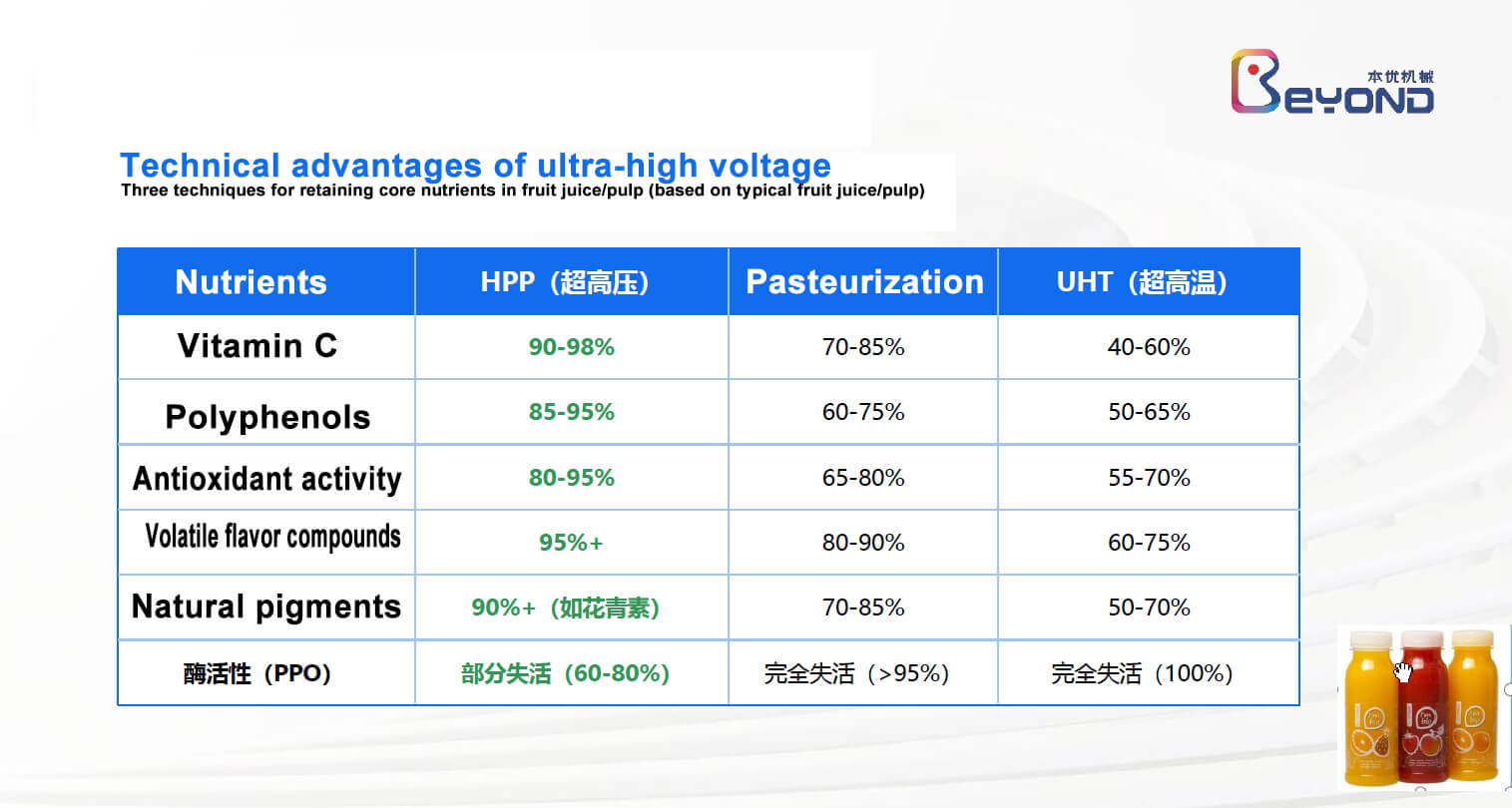

From cold-pressed juice to ready-to-eat meats, the food sector is rapidly embracing High Pressure Processing of food as the preferred non-thermal alternative to heat pasteurization. A modern HPP juice machine subjects already-sealed bottles to 400–600 MPa of hydrostatic pressure for 1–3 min, rupturing membranes of Salmonella, Listeria and E. coli without exposing the product to elevated temperature . Because water transmits pressure uniformly, vitamins, enzymes and color remain largely intact, allowing brands to deliver “clean-label” beverages that keep 45–60 days under refrigeration—double or triple the life of traditional cold-pressed juice .

Recent equipment trends focus on bigger, faster and smarter systems. The largest commercial vessels now exceed 525 L and can treat roughly 3 000 kg of beverage per hour; modular intensifier blocks allow processors to add pump capacity as demand grows, protecting initial capital . Robotic basket loading/unloading and cloud-based pressure logging reduce direct labor, while in-bulk modules enable continuous treatment of purées or dairy bases, moving HPP from batch to quasi-continuous operation . Hybrid high-pressure thermal processing (HPTP) canisters—slipped inside existing machines—add controlled temperature spikes, pushing the technology toward true ambient shelf stability without the flavor “cook” typical of retorting .

News

Hot Product