Ultra high pressure sterilization

High Pressure Processing (HPP) is a non thermal processing technology that applies pressure at room or low temperatures (usually 400-600 MPa) to maximize the retention of heat sensitive components such as vitamin C and polyphenols, avoiding nutrient loss and flavor changes caused by traditional heat sterilization. For example, the vitamin C retention rate of HPP orange juice can reach over 95%, while only 60-70% remains after thermal processing.

Ultra high pressure sterilization is a "green revolution" in the food industry, especially suitable for high-end cold and fresh foods and healthy drinks. With the popularization of technology and the increasing demand for "additive free" products from consumers, the market potential is enormous, especially in high profit categories such as organic juices, high-end pre made dishes, and baby food.

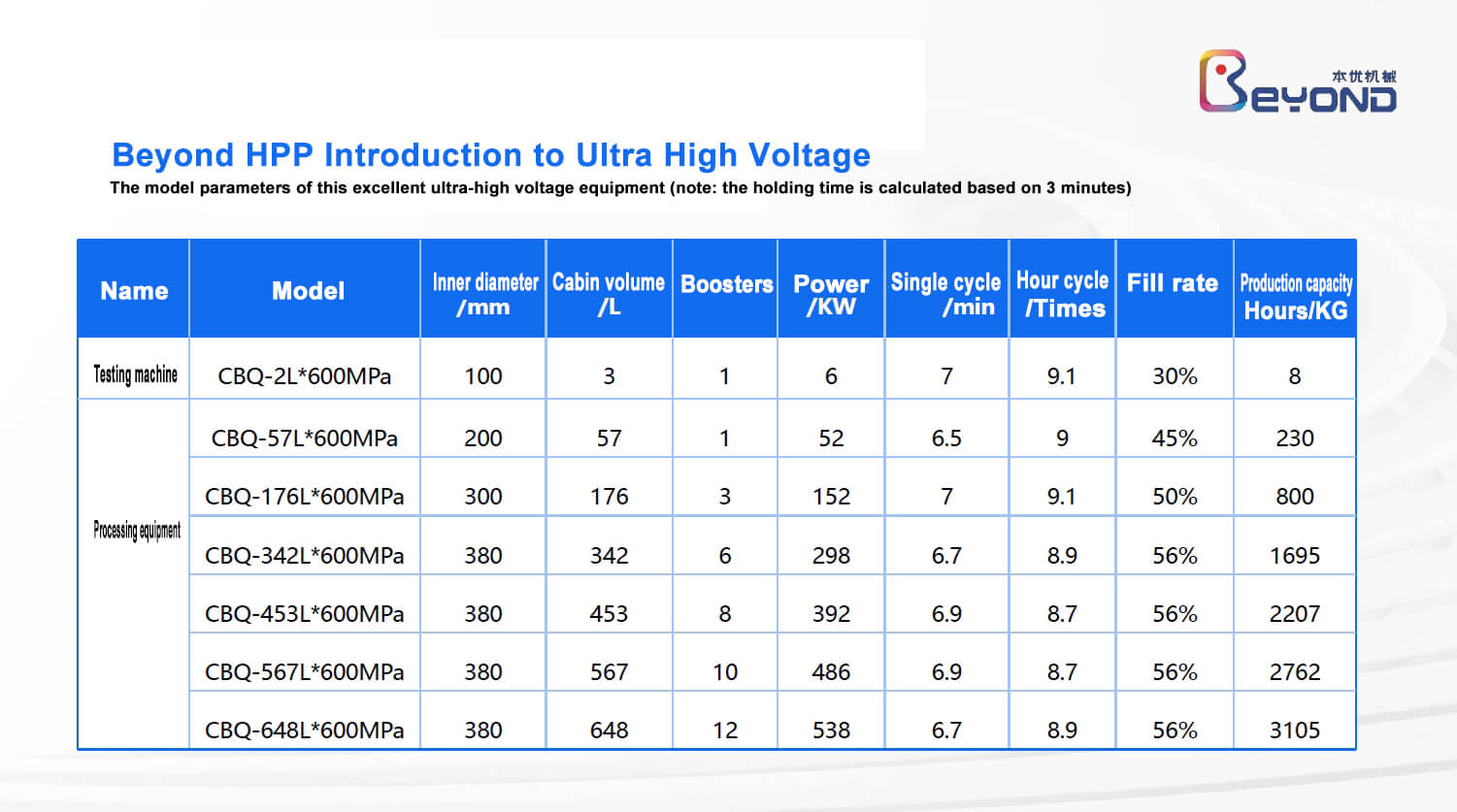

1、 Model parameters of ultra-high voltage equipment (Note: The holding time is calculated based on 3 minutes.)

Advantages of Beyond Ultra High Voltage (HPP)

Host part: design aspect

Domestically, imitation technology is widely used;

Advantage 1: This product adopts computer-aided design, finite element analysis, and actuarial technology for research and development, ensuring product safety, stability, and reliability.

Host part: Ultra high pressure cylinder body

Carbon steel and thin stainless steel inner liners are commonly used domestically - they are prone to damage, frequently replaced, and require long maintenance times,

High cost.

Advantage 2: This product uses imported ultra hard special stainless steel barrels - although the one-time cost is high

During the use of the equipment, there is no need for replacement, maintenance, or major repairs, and no expenses incurred.

Advantage 3: This product adopts a sleeve integral design - high cost and heavy weight. But it belongs to 'hard' protection,

No replacement, maintenance, or cost is required during the use of the device.

The difference between domestic and foreign wrap around hosts:

Abroad - finite element design, configuration of lubrication and temperature control systems, forming a device; Maintenance lifespan, 20000 cycles.

Domestically - imitation, simplified calculation, without lubrication or temperature control system, only counted as one component; Due to stretching and stress deformation, after working less than 10000 times, there will be problems such as inability to apply pressure, inability to maintain pressure, unstable equipment, and solution leakage. It is necessary to return to the factory for repair. )

Design method of force frame for host part (III):

Wrapping type - In China, it is generally only steel wire winding without protective measures. Over time, the steel wire will stretch and the pressure will not increase, making it difficult to maintain. It must be returned to the factory for repair or downgraded (such as up to 400MPa) for use.

Welding type - hot cutting, welding forming, extremely low cost, but extremely high risk, pressure drops for a period of time

Advantage 4: Our company adopts the most advanced international technology of overall cold cutting. Capable of withstanding extreme pressure work for 5 years or 100000 times, maintenance free.

Waterway system: including ultra-high pressure waterway system and low pressure waterway system

Universal open waterway system: After the work cycle is completed, the water in the high-pressure chamber is directly discharged, which is wasteful, causes significant pollution, and has a poor environment.

Advantage 5: This advantage adopts a closed-loop waterway system

High and low pressure water recycling, low emissions, energy-saving and environmentally friendly.

Advantage 6: This product adopts an in warehouse temperature control system (optional) with unique domestic technology,

The temperature inside the warehouse can be adjusted according to customer needs for effective sterilization.

Ultra high voltage source system:

Domestic ultra-high pressure booster system: - Cheap and cost-effective.

This product adopts an imported component ultra-high pressure supercharger system. --Good stability, high efficiency, and high cost.

Conventional turbocharger power system - cheap price, hard start, high equipment vibration, and key components such as turbocharger ceramic rod are prone to damage.

This product adopts a variable frequency motor booster power system. --The internationally advanced power system belongs to soft start and soft stop, with stable operation and long service life of components, but the coverage has been significantly increased.

Operating Execution System:

Hydraulic conventional plug opening and closing centering system:

Simple structure and low cost; However, the operation of the blockage and silo, as well as the stability in the middle, require manual calibration, which can easily lead to deviation and collision accidents;

Conventional operating system:

Without an oil and water protection system, after multiple operations, the high oil temperature leads to the inability to maintain pressure, resulting in oil leakage and unstable production, causing environmental hazards;

Advantage 7: This advantage adopts a foolproof intelligent plug opening and closing centering system:

By adopting precision control technology of CNC machine tools, intelligent one click operation is achieved, effectively avoiding friction and collision between equipment, eliminating safety hazards, ensuring continuous work, reducing repair time, and lowering repair costs;

Advantage 8: This advantage adopts an intelligent operation protection system:

Establish oil and water overheating and overcooling protection systems to ensure safe, stable, continuous, and environmentally friendly operation of equipment;

Advantage 9: This advantage adopts an intelligent control system:

Host control system; Waterway control system; Ultra high voltage source control subsystem; Operation execution control subsystem;

Acceptance criteria:

Acceptance of foreign ultra-high voltage equipment:

570MPa, One shift (8 hours) continuous production, equipment stable and normal;

Advantage 10: Acceptance criteria for our superior ultra-high voltage equipment:

570MPa, Two shifts (16 hours) of continuous production with stable and normal equipment;

The existing equipment of other domestic manufacturers cannot achieve continuous production for more than 10 hours;