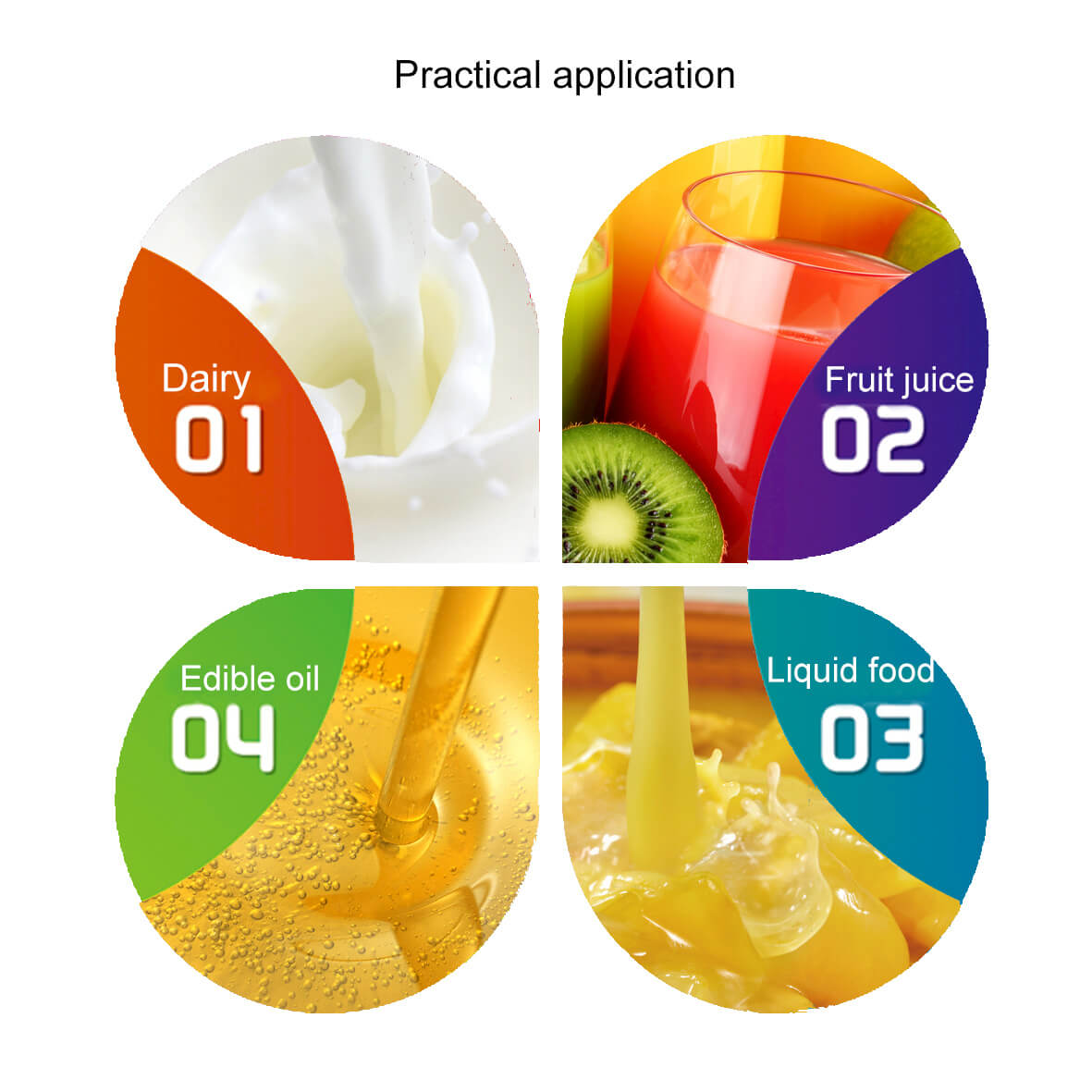

Tubular UHT Sterilizer is a type of sterilization equipment used in the food and beverage industry. It is specifically designed to heat and sterilize liquid products such as milk, juices, and sauces.

The sterilizer consists of a series of stainless steel tubes through which the product flows. The tubes are heated using steam or hot water, raising the temperature of the product to ultra-high temperatures (UHT) for a short period of time. This process effectively kills any microorganisms present in the product, ensuring its safety and extending its shelf life.

Tubular UHT Sterilizers offer several advantages, including efficient heat transfer, uniform heating, and minimal product degradation. They are widely used in the production of long-life dairy products, fruit juices, and other beverages.

It's worth noting that Tubular UHT Sterilizers require proper maintenance and cleaning to ensure optimal performance and prevent contamination.

Usage:

This machine stands between the pasteurizer and the UHT, can be used for PET hot filling or roof shape filling sterilize.

Full automatic control: UK Spirax Sarco steam pressure reduce valve, German Burkert or Spirax Sarco temperature control system, German Labom temperature transducer, Anthone temperature recorder without paper, South hot water pump, Siemens PLC full automatic control with touch screen, the precision of temperature control is ±0.5 degree.

Semiautomatic control: UK Spirax Sarco steam pressure reduce valve, German Burkert or Spirax Sarco temperature control system, German Labom temperature transducer, Anthone temperature recorder without paper, South hot water pump, Siemens LOGO control, the precision of temperature control is ±0.5 degree.

Technical parameters:

Sterilizing procedures: (1)5ºC→65ºC(homogenizer)→137ºC(3-5S)→20ºC-25ºC,for aseptic filling;

(2)5ºC→65ºC(homogenizer)→115ºC/125ºC(5-15S)→88ºC-90ºC,for hot filling;

(3)5ºC→65ºC(homogenizer)→115ºC/125ºC(5-15S)→75ºC-

This machine is used to perform continuous sterilization on juice and beverage, milk, and similar products.

This system can be connected with homogenizer and degasser.

Equipment Advantages:

High heat efficiency, 90% of heat can be reused after the product be processed;

Temperature difference between the product and the heating medium is small, so the heating is gentle; the heating tubular adopts wave pipes, the material and the medium are both in flow;

It is of high degree automatic, can automatically control the CIP cleaning, self sterilizing, and the whole procedures steps; all the procedures are recorded and controllable.

It is of precise and reliable sterilizing temperature control; all the affecting factors such as steam pressure, steam flow rate, product flow rate are all controllable;

The inside of the tubular adopts advanced polish procedure, all tubes can perform fully cleaning, self sterilizing ensures the system at aseptic state;

Standard configuration:

A. plate heat exchanger;

B. material-balance drum;

C. hot water-balance drum;

D. pump of hot water charging;

E. pump of material transferring;

F. hot water making machine;

G. electricity box;

H. valves and pipes of stainless steel etc.

Control elements list:

|

Semi-automatic control configuration |

Item |

Brand or supplier |

|

Controller |

Siemens LOGO |

|

|

Reducer valve |

Spirax Sarco from UK |

|

|

Temperature control system |

Burkert or Spirax Sarco |

|

|

Temperature transducer |

Labom from Germany |

|

|

Temperature recorder without paper |

Anthone |

|

|

Pipes and valves |

Shanghai Yuanan |

|

|

Hot water pump |

From Italy |

|

|

Precision of temperature control is ±0.5 degree |

||

|

Full automatic control configuration |

Item |

Brand or supplier |

|

Controller |

Siemens Touch-screen PLC |

|

|

Reducer valve |

Spirax Sarco from UK |

|

|

Temperature control system |

Burkert or Spirax Sarco |

|

|

Temperature transducer |

Labom from Germany |

|

|

Pipes and valves |

Shanghai Yuanan |

|

|

Hot water pump |

From Italy |

|

|

Precision of temperature control is ±0.5 degree |

||

Parameter

|

Model |

Capacity |

Heat exchange area(m²) |

Power (kw) |

Steam consumption (kg/h) |

Dimension (L×W×H)mm |

Machine weight (kg) |

|

BR16-UB-1 |

1 t/h |

10 |

5.2 |

120 |

1500×1500×1800 |

980 |

|

BR16-UB-2 |

2 t/h |

18 |

5.2 |

210 |

2200×2000×1800 |

1050 |

|

BR26-UB-3 |

3 t/h |

26 |

6 |

280 |

2400×2000×2200 |

1450 |

|

BR26-UB-4-5 |

4 -5t/h |

32-40 |

6 |

340 |

2600×2000×2200 |

1680 |

|

BR26-UB-6-8 |

6 -8t/h |

35-50 |

8 |

400 |

2800×2000×2200 |

1720 |

|

BR26-UB-10 |

10t/h |

60-70 |

11 |

450 |

2800×2000×2200 |

1720 |

|

BR26-UB-15 |

15t/h |

70-75 |

15 |

550 |

2800×2000×2200 |

1720 |

|

BR26-UB-20 |

20t/h |

75-80 |

15 |

620 |

3000×2000×2200 |

1720 |