A plate sterilizer, also known as a plate heat exchanger, is another type of sterilization equipment commonly used in the food and beverage industry. It is designed to heat and sterilize liquid products through a series of metal plates.

The plate sterilizer consists of several plates with corrugated patterns to create turbulence and increase the heat transfer efficiency. The liquid product flows between the plates, while steam or hot water is circulated on the other side. This allows for rapid and efficient heat transfer, quickly raising the temperature of the product to the desired sterilization level.

Plate sterilizers are particularly suitable for low-viscosity liquids, such as fruit juices, sauces, and soups. They offer advantages such as compact design, high heat transfer rates, and easy maintenance. They are also capable of handling large volumes of product with minimal energy consumption.

Like Tubular UHT Sterilizers, plate sterilizers need regular cleaning and maintenance to prevent fouling and ensure proper operation. This includes periodic disassembly and inspection of the plates to remove any deposits or buildup that may affect performance.

Field of application:juice beverage and other liquid food industries. The tubular heat exchanger unit is designed for sterilizing and cooling of milk and juice as well as products containing fibers and particles. The sterilization temperature is typically 135℃~ 140℃for 4 seconds holding. .

Standard design: The unit is pre-assembled and tested before it leaves the factory. The installation on site only require connection to external service such as product inlet and outlet, water, steam, air and electricity.

The unit comprises:

- Frame

- Set of tubular heat exchangers with:

Regenerating section

Sterilization section

Hot water section

Cooling section

- Balance tank

- Product pump

- Holding tube

- Hot water pump

- Control panel with:

PLC controller

Color Human Machine Interface

Alarm for high and low temperature

Alarm for high temperature and low flow in hot water section

Start/stop buttons for pumps

Indicator for and control of pasteurizing temperature

- Set of internal pipes, valves and fittings

The unit is designed for CIP via recirculation over the balance tank and dosing of chemicals automatically.

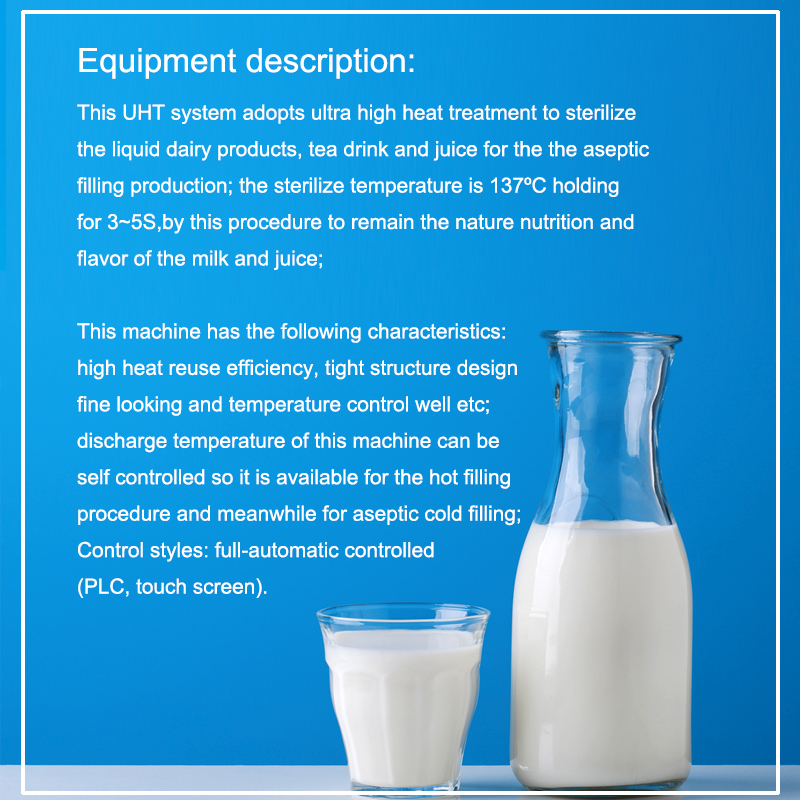

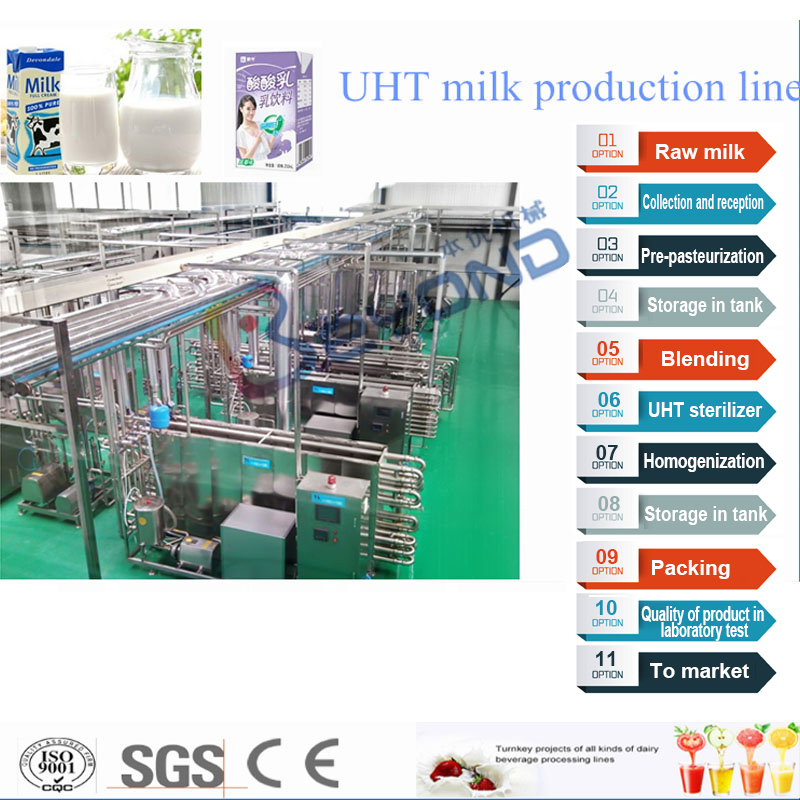

Technicals: 5℃→65℃(homogenizer)→137℃(3-5S)→20℃-25℃. This UHT system adopts ultra high heat treatment to sterilize the liquid dairy products, tea drink and juice for the the aseptic filling production; the sterilize temperature is 137℃ holding for 3~5S,by this procedure to remain the nature nutrition and flavor of the milk and juice;

This machine has the following characteristics: high heat reuse efficiency, tight structure design fine looking and temperature control well etc; discharge temperature of this machine can be self controlled so it is available for the hot filling procedure and meanwhile for aseptic cold filling;

|

Model |

Production capacity L/H |

Temperature |

Holding

time

(s)

|

Sterilize temperature |

Product outlet temperature |

Steam consumption |

Compressed air pressure |

Compressed air consumption |

External

diamension

(mm)

|

Total weight of machine |

|

LG-UHT-1 |

1000 |

5℃ |

4-15 |

105~143℃ |

20 ℃ |

~150Kg/h |

0.6MPa |

50L/H |

3500×2000×2500 |

1700kg |

|

LG-UHT-2 |

2000 |

5℃ |

4-15 |

105~143℃ |

20 ℃ |

~210Kg/h |

0.6MPa |

50L/H |

3500×2000×2500 |

2000Kg |

|

LG-UHT-3 |

3000 |

5℃ |

4-15 |

105~143℃ |

20 ℃ |

~280Kg/H |

0.6MPa |

60L/H |

4500×2500×2200 |

2200Kg |

|

LG-UHT-4 |

4000 |

5℃ |

4-15 |

105~143℃ |

20 ℃ |

~350Kg/h |

0.6MPa |

60L/H |

5000×2000×2200 |

2500Kg |

|

LG-UHT-5 |

5000 |

5℃ |

4-15 |

105~143℃ |

20 ℃ |

~420Kg/h |

0.6MPa |

70 L/H |

5000×2000×2200 |

2800kg |