HTST stands for High Temperature Short Time and refers to a method of pasteurization used in the food and beverage industry. In this process, a product is heated to a high temperature (usually around 72°C/161°F) for a short period of time (typically 15-20 seconds) before being rapidly cooled. This method helps to kill harmful bacteria and extend the shelf life of the product without significantly altering its taste or nutritional value.

The plate HTST system consists of a series of heat exchangers (plates) through which the product flows. The plates are typically made of stainless steel and are designed to maximize heat transfer efficiency. The product is pumped through one side of the plate while hot water or steam is pumped through the other side. As the product passes through the plates, it is heated to the desired temperature and then quickly cooled down using cold water or chilled media.

Plate HTST pasteurization is widely used in the dairy industry for milk and other dairy products. It is also commonly used for fruit juices, sauces, soups, and other liquid foods. This method offers several advantages such as faster processing times, minimal product loss, energy efficiency, and high quality pasteurization.

Application

Mainly applied in integrity factories which produce multiform products;

Widely applicable in production of pasteurized milk, yogurt, UHT milk, beverage, juice, tea etc.

And this equipment can be connected with separator, homogenizer, flash evaporation etc.

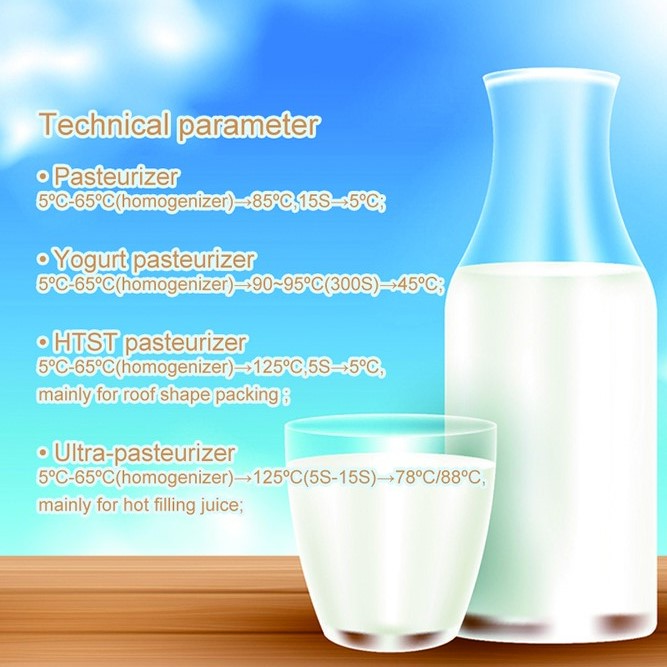

Technical flow design:

pasteurizer: 5℃→65℃(homogenizer)→85℃,15S→5℃;

yogurt pasteurizer: 5℃→65℃(homogenizer) → 90~95℃(300S)→45℃;

HTST pasteurizer: 5℃→65℃(homogenizer)→125℃,5S→5℃,mainly for roof shape packing;

Ultra-pasteurizer: 5℃→65℃(homogenizer)→125℃(5S-15S)→78℃/88℃,mainly for hot filling juice.

Control elements list:

|

Semi-automatic control configuration |

Item |

Brand or supplier |

|

Controller |

Siemens LOGO |

|

|

Steam pressure reducer valve |

Spirax Sarco from UK |

|

|

Temperature control system |

Germany Burkert or Spirax Sarco |

|

|

Temperature transducer |

Labom from Germany |

|

|

Temperature recorder without paper |

Anthone |

|

|

Pipes and valves |

Shanghai Yuanan |

|

|

Hot water pump |

From Italy |

|

|

Precision of temperature control is ±0.5 degree |

||

|

Full automatic control configuration |

Item |

Brand or supplier |

|

Controller |

Siemens Touch-screen PLC |

|

|

Steam pressure reducer valve |

Spirax Sarco from UK |

|

|

Temperature control system |

Germany Burkert or Spirax Sarco |

|

|

Temperature transducer |

Labom from Germany |

|

|

Temperature recorder without paper |

Anthone |

|

|

Pipes and valves |

Shanghai Yuanan |

|

|

Hot water pump |

From Italy |

|

|

Precision of temperature control is ±0.5 degree |

||

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

| Model | Process capacity | Heat exchanging area(m²) | Power (Kw) | Steam cost(kg/h) | External diamension (mm) | Total weight of machine(kg) |

| BR16-5-1 | 0.5 | 10 | 5.2 | 110 | 1500*1500*1800 | 980 |

| BR16-5-2 | 1T/H | 18 | 5.2 | 160 | 2200*2000*1800 | 1050 |

| BR26-5-3 | 2T/H | 26 | 6 | 190 | 2400*2000*2200 | 1450 |

| BR26-5-4-5 | 3T/H | 32-40 | 6 | 320 | 2600*2000*2200 | 1680 |

| BR26-5-6-8 | 4-5T/H | 35-50 | 8 | 523 | 2800*2000*2200 | 1720 |

| BR26-5-10 | 6-8T/H | 60-70 | 11 | 630 | 2800*2000*2200 | 1790 |

| BR26-5-15 | 15T/H | 70-75 | 15 | 981 | 2800*2000*2200 | 1850 |

| BR26-5-20 | 20T/H | 75-80 | 15 | 1309 | 3000*2000*2200 |

1950 |