Cheese Vertical Melting Tank is a specialized equipment used for processing and melting cheese, commonly found in cheese production factories or places in the catering industry where cheese products are made. This type of equipment is mainly used to quickly and uniformly heat large or hard cheese to a suitable melting state.

Its design features include:

1. Vertical structure: Adopting a vertical layout, effectively utilizing space, and facilitating material handling and temperature control.2. Heating system: Equipped with efficient electric heating elements or steam heating devices inside, it can accurately control the melting temperature, ensure that the cheese melts under optimal conditions, and prevent excessive heating from causing a decrease in quality.

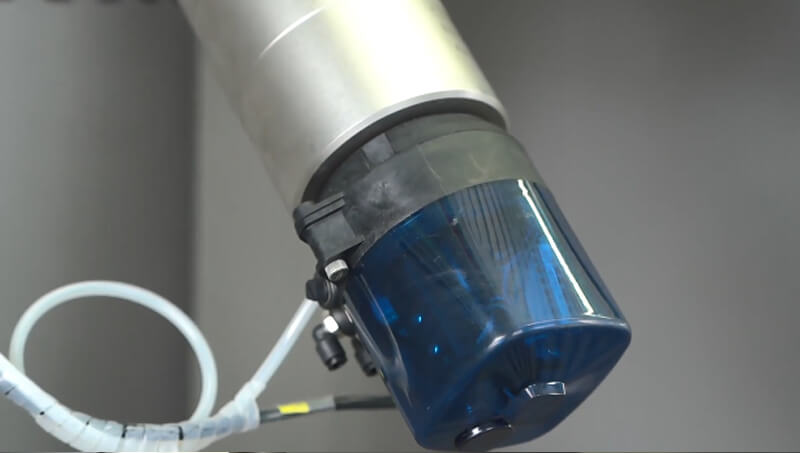

3. Mixing system: Usually equipped with a mixer, it can evenly mix and disperse melted cheese, avoid clumping and local overheating, and ensure consistency in product quality.

4. Safety and hygiene: Made of food grade stainless steel materials that comply with food safety standards; And it is easy to clean and disinfect to maintain good hygiene conditions. The cheese vertical melting pot is widely used in the production of various cheese products, such as cheese ingredients on pizza, cheese sauces, lava cheese, etc., providing an efficient and convenient cheese processing solution for the catering industry.

The cheese vertical melting pot adopts multiple advanced technologies to ensure efficient, precise, and hygienic cheese processing:

1. Accurate temperature control technology: Equipped with advanced temperature sensors and control systems, it can monitor and accurately adjust the temperature inside the melting pot in real time, ensuring that the cheese melts uniformly at the optimal melting point, avoiding excessive heating that affects the taste and nutritional content.2. Intelligent mixing system: Adopting an intelligent or variable frequency driven mixing device, it can automatically adjust the mixing speed and direction according to the melting state of the cheese, ensuring that the melted cheese has a delicate texture and no lumps.

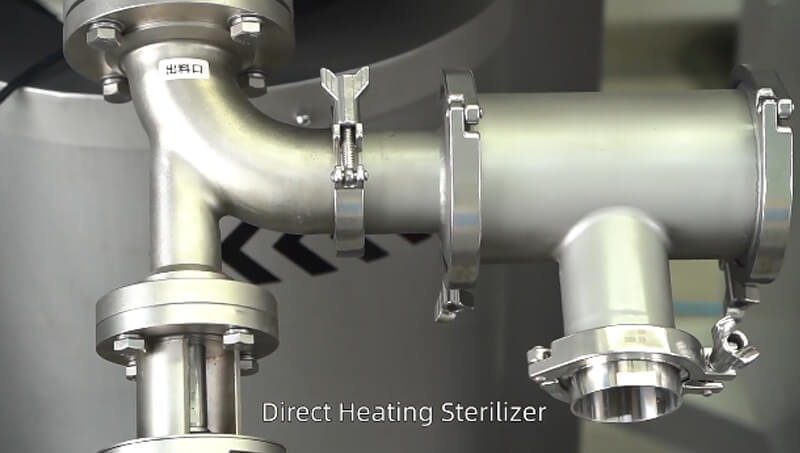

3. Efficient heat exchange technology: Utilizing efficient electric heating elements, steam heating, or hot water circulation and other multimodal heating methods, it can quickly improve melting efficiency and reduce energy consumption.

4. Food grade materials and surface treatment: Made of advanced food grade stainless steel materials and finely polished to ensure equipment safety and hygiene, easy cleaning and maintenance, and compliance with food safety regulations.

5. Automation control system: Integrate PLC (programmable logic controller) or touch screen operation interface to achieve functions such as one key start, program preset, automatic alarm, etc., improve production efficiency, and reduce human operation errors.

6. Energy saving optimization design: Some advanced equipment adopts excellent insulation layers and heat recovery systems, which minimize energy loss and help maintain a stable melting environment.

7. Modular structure: Easy to disassemble and assemble, convenient for equipment maintenance and upgrading, and can also flexibly configure different capacity specifications according to different production requirements.

Through the application of the above advanced technologies, the vertical cheese melting pot not only improves the quality and efficiency of cheese processing technology, but also further ensures the safety and quality of food.

Vertical Melting Tank for Food is a widely used processing equipment in the food industry, mainly used for high-temperature heating and melting treatment of solid or semi-solid food raw materials. This type of equipment is usually designed with advanced temperature control systems, mixing systems, and safe and hygienic material structures to ensure efficient and uniform melting of materials while maintaining food quality.

Its main functions and uses include:

2. Standardized production: In the food processing process, especially in mass production of ice cream blends, candy fillings, baking premixes, and various seasonings, the vertical melting pot can accurately control the melting temperature and time to ensure product consistency.

3. Sterilization and disinfection: Some melting pots also have sterilization functions, which can perform pasteurization or other heat treatment processes on materials while melting, effectively killing bacteria and microorganisms, and improving food safety.

4. Storage and insulation: The melted food can be kept at a certain temperature in the pot for continuous operation in subsequent processing steps, and can also be stored for a short time to avoid cooling and solidification.

5. Strong adaptability: Vertical melting pots can be customized and designed according to the characteristics of different products and production process requirements, such as equipping strong mixers for high viscosity materials, or adopting different heating methods to adapt to different types of food raw materials.