A yogurt pasteurizer with four sections is a specialized piece of equipment used for heating and cooling milk to make yogurt. It follows a similar principle as a plate pasteurizer, but with additional sections tailored specifically for yogurt production.

The four sections of the yogurt pasteurizer generally consist of a preheating section, a heating section, a fermentation section, and a cooling section.

In the preheating section, the milk is gently heated to remove any cold spots and bring it to a uniform temperature. This step helps in activating the cultures and enzymes present in the milk, which are necessary for the fermentation process.

Next, the milk enters the heating section, where it is rapidly heated to a specific temperature, typically around 85-90 degrees Celsius (185-194 degrees Fahrenheit). This high temperature kills any harmful bacteria and ensures that the milk is safe for consumption.

After the heating section, the milk moves into the fermentation section, where it is cooled down to a temperature suitable for the growth of yogurt cultures. This temperature is usually around 40-45 degrees Celsius (104-113 degrees Fahrenheit). In this section, the milk is held at the desired temperature for a specific duration, typically 4-8 hours, to allow the cultures to convert lactose into lactic acid, resulting in the thickening and tangy flavor characteristic of yogurt.

Finally, the yogurt enters the cooling section, where it is rapidly cooled down to halt the fermentation process and prevent further acidification. The cooling temperature depends on the desired texture and consistency of the yogurt, typically ranging from 5-10 degrees Celsius (41-50 degrees Fahrenheit).

The four-section yogurt pasteurizer is commonly used in small to medium-scale dairy operations or yogurt production facilities. It provides precise control over the heating, fermentation, and cooling processes, ensuring consistent quality and safety in the final yogurt product.

Application

This machine is specially designed for yogurt production, the technical parameters are as following:

inlet at 5℃→65℃(homogenizer) →sterilize at 90~95℃(hold for 300S)→ outlet at 43℃.

This system adopts 90~95℃, holding for 5 minutes, which ensures to get a most suitable pasteurize efficiency. And also this system makes the most of the whey protein denaturation to form block shape and combine with water, so as to produce stable quality, good taste of yogurt.It is the best choice of the yogurt processing in milk plant.

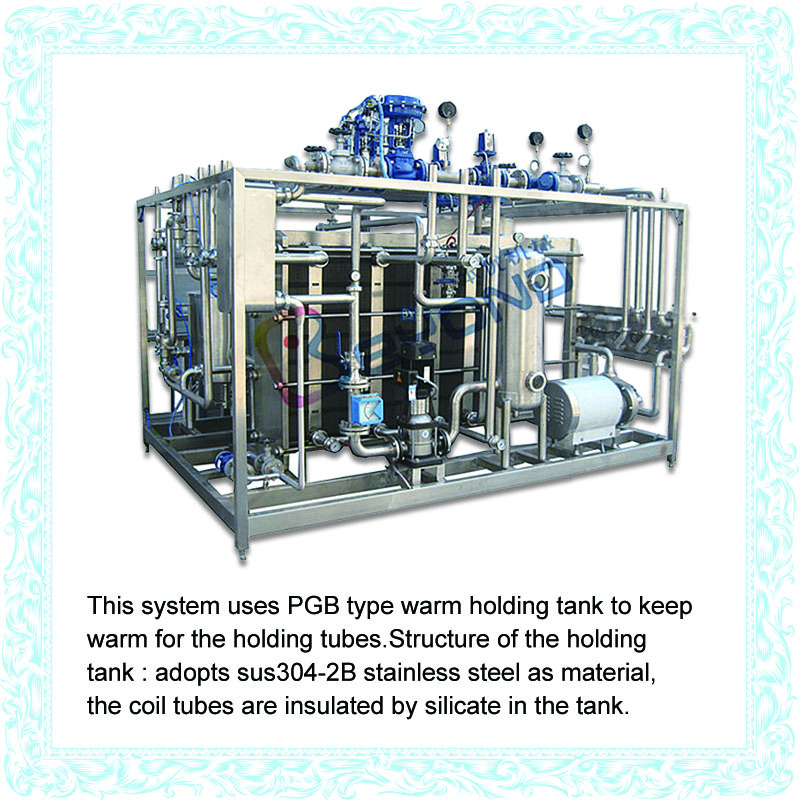

This system uses PGB type warm holding tank to keep warm for warm for holding tubes.Structure of the holding tank : adopts sus304-2B stainless steel as material, the coil tubes are insulated by silicate in the tank.

Technical Parameter:

|

Model |

Capacity |

Heat exchange area(m²) |

Power (kw) |

Steam consumption (kg/h) |

Dimension (L×W×H)mm |

Machine weight (kg) |

|

BR16-SN-05 |

0.5 t/h |

5 |

5.2 |

80 |

1200×1200×1800 |

780 |

|

BR16-SN-1 |

1 t/h |

8 |

5.2 |

120 |

1500×1500×2000 |

950 |

|

BR16-SN-1.5 |

1.5 t/h |

11 |

6 |

160 |

2000×1600×2000 |

980 |

|

BR16-SN-2 |

2 t/h |

14 |

6 |

190 |

2200×2000×2500 |

1020 |

|

BR16-SN-3 |

3 t/h |

21 |

8 |

220 |

2400×2000×2500 |

1120 |

|

BR26-SN-5 |

5 t/h |

30 |

11 |

350 |

2600×2000×2500 |

1260 |

|

BR26-SN-10 |

10 t/h |

54 |

11 |

620 |

2800×2000×2500 |

1680 |

Material SUS304, Semi-auto PID control, famous brand steam pressure reduce valve, regulating valve, drain valve, famous brand temperature sensor, with CIP cleaning function, frame support, stainless steel control cabinet, famous brand electric componets.

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

Related machinery of dairy(cheese, butter, milk, yoghurt,cream) processing line

Large outdoor storage tank, agitator tank, jacket tank, ferment growing tank, emulsification tank, milk weighing, milk receiving/collecting, extracting, pasteurizer yoghurt, UHT, HTST pasteurizer, plate pasteurizer, tubular UHT sterilizer, spraying type pasteurization, cooling tunnel, bottle tilting sterilization chain, CIP cleaning system, full-auto CIP, semi-auto CIP, evaporator, curd cutting, whey draining, cheese making, scalding/stretching/molding, cheese vat, mozzarella cheese, cheddar cheese, blending system, pre-pasteurization, cream separator system, powder melting, dissolving system, homogenizer system, turn-key project.