A full-automatic degassing machine is a device used for removing gases or air bubbles from liquids. It is commonly used in various industries such as food and beverage, pharmaceuticals, and electronics manufacturing. The machine utilizes various mechanisms such as vacuum pumps and agitation to effectively remove gas from the liquid.

Some key features of a full-automatic degassing machine may include:

Automated operation: The machine is designed to operate automatically, reducing the need for manual intervention and increasing efficiency.

Vacuum degassing: The machine creates a vacuum environment to remove gas or air bubbles from the liquid. This process helps to improve the quality and stability of the liquid.

Agitation mechanism: The machine may incorporate an agitation system that helps to accelerate the removal of gas from the liquid. This can be achieved through the use of rotating blades or other mechanisms.

Adjustable settings: The machine allows for adjusting parameters such as vacuum level, agitation speed, and degassing time to suit different liquid types and requirements.

Monitoring and control: A full-automatic degassing machine may have built-in sensors and controllers to monitor and regulate the degassing process. This ensures consistent performance and prevents over-degassing or under-degassing.

Safety features: The machine may include safety mechanisms such as pressure sensors, emergency stop buttons, and alarms to ensure safe operation.

When considering a full-automatic degassing machine, it is important to evaluate factors such as the capacity, compatibility with the liquid being processed, ease of maintenance, and overall reliability.

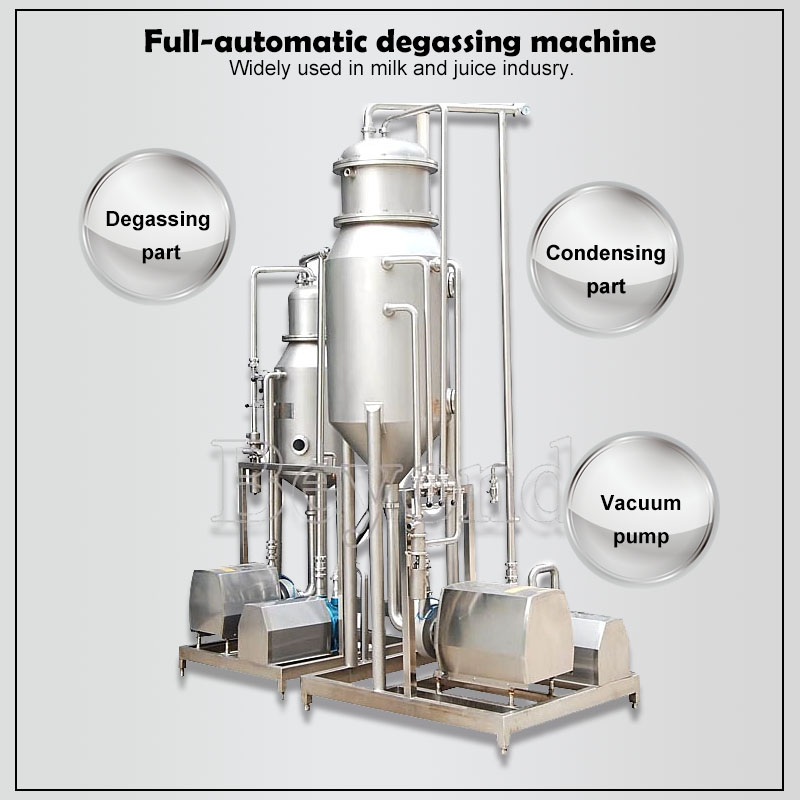

Description: this equipment adopts vacuum system to remove the smelly and oxygen in the milk and juice;

Construction: this equipment is composed of degassing part、condensing part、vacuum pump etc;Use: widely used in milk and juice industry.

The control model can be manual type or full auto control;

Characteristics:

1. Remove the smelly and oxygen by thoroughly

2. With condensing part to re-collect the flavor;

3. Can be connected with the pasteurizer and work together;

Technical:

| Model | Capacity |

External dimension L×W×H (mm) |

Ice water consumption (Kcal) |

Suggested power (KW) |

|

TQ-2 |

2(T/h) | 1100×1200×2800 | ≤1 | 5.5 |

| TQ-3 | 3(T/h) | 1100×1200×2800 | ≤1.5 | 6 |

| TQ-5 | 5(T/h) | 1100×1200×3000 | ≤2.5 | 7.5 |

| TQ-6 | 6(T/h) | 1200×1400×3500 | ≤3 | 9 |

| TQ-8 | 8(T/h) | 1400×1700×4000 | ≤4 | 12 |

| TQ-10 | 10(T/h) | 1400×1700×4000 | ≤5 | 15 |

| TQ-12 | 12(T/h) | 1600×2000×4200 | ≤6 | 22 |

| TQ-15 | 15(T/h) | 1700×2200×4200 | ≤7 | 22 |