A double effect evaporator is a type of heat exchanger used in the process of evaporation. It is designed to efficiently remove water or other solvents from a liquid mixture by applying heat.

The double effect evaporator consists of two separate evaporator chambers, known as effects, connected in series. Each effect operates at a different temperature and pressure, allowing for multiple stages of evaporation.

In the first effect, heat is applied to the liquid mixture, causing the solvent to evaporate. The resulting vapor is then condensed and collected as a concentrated liquid in the second effect. This concentrated liquid is then heated in the second effect, causing further evaporation and condensation in a third effect, if present.

The advantage of a double effect evaporator is that it can achieve a higher concentration of the desired product compared to a single effect evaporator, while using less energy. By utilizing the hot vapor generated in the first effect to heat the liquid in the second effect, the double effect evaporator reduces the amount of external heat required.

Overall, a double effect evaporator is a more efficient and cost-effective solution for industrial processes that require the concentration of liquids or the removal of solvents.

Application

Two effect evaporator:this equipment adopts two effect falling film to evaporate the water in the milk and fruit juice;

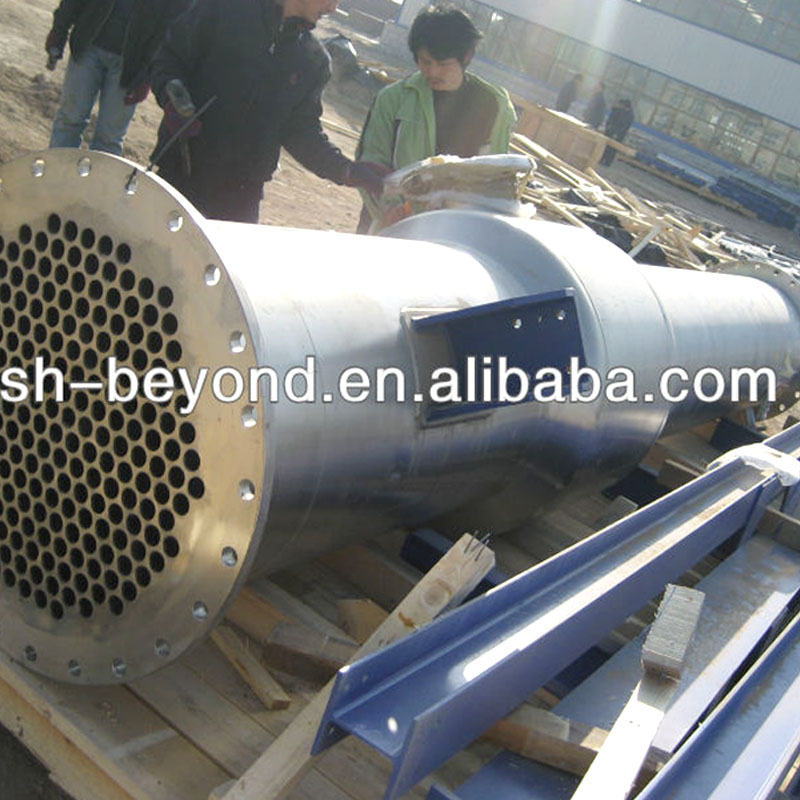

Construction:evaporator,separator,condenser etc.Use:popularly used for concentrating and dehydration in food,biology engineering,pharmacy and chemistry etc.

Automatic control:manual operated and full auto control;

Characteristics

1、Adopts twin effect type,high use factor of steam,low energy consumption;

2、Full closed process,fast and low temperature evaporation,so the nature color and flavor and smell is well remained.

3、Heating fast with high efficiency and strong capability of anti-scaling.

4、Large scale of the concentrate rations the products between the different effects can recycle separately,so the concentrate ratio can be regulated in large scale.

Technical parameter

|

Model

|

Evaporation capacity of water

|

External dimension

(L×W×H) |

Steam consumption

(kg/h) |

Power

|

|

JNS-2-0.8

|

≤0.8(T/H)

|

4500*2500*7000

|

≤0.45(T/H)

|

20

|

|

JNS-2-1

|

≤1(T/H)

|

4500*2500*7200

|

≤0.55(T/H)

|

22

|

|

JNS-2-1.5

|

≤1.5(T/H)

|

4800*3000*7600

|

≤0.8(T/H)

|

30

|

|

JNS-2-2

|

≤2(T/H)

|

4800*3000*7800

|

≤1.1(T/H)

|

30

|

|

JNS-2-3

|

≤3(T/H)

|

4800*3200*7800

|

≤1.65(T/H)

|

35

|