UHT pure milk is to heat fresh milk to 135 ℃ ~ 150 ℃ under continuous flow and keep it for 2S ~ 5S On the premise of effectively killing microorganisms, the milk produced by this method retains the nutrients in the milk to the greatest extent and can be preserved for a long time at room temperature.

Quality control UHT processing of milk

1. Heating is an essential and important process for UHT milk products, but different sterilization temperatures and times should be adopted for different products to ensure the original flavor of the products. If consistent sterilization conditions are adopted, the original flavor of the products will be destroyed. According to the actual situation, there are mainly three situations as follows:

a. For acidic drinks, some of the microorganisms that may be produced under acidic conditions are heat-resistant microorganisms, so the sterilization temperature should not be too high. At the same time, it is also prevented that too high temperature will cause acid odor in the sour agent in the product. Therefore, it is generally controlled at 115 ~ 120 ℃ for 4 s.

b. When raw materials containing spores or heat-resistant spores (such as cocoa powder, coffee powder and milk powder) are used to produce fancy powder or neutral milk beverage, the sterilization temperature shall be appropriately increased to kill these spores as far as possible. Generally, 139 ~ 142 ℃ is used for 4 s.

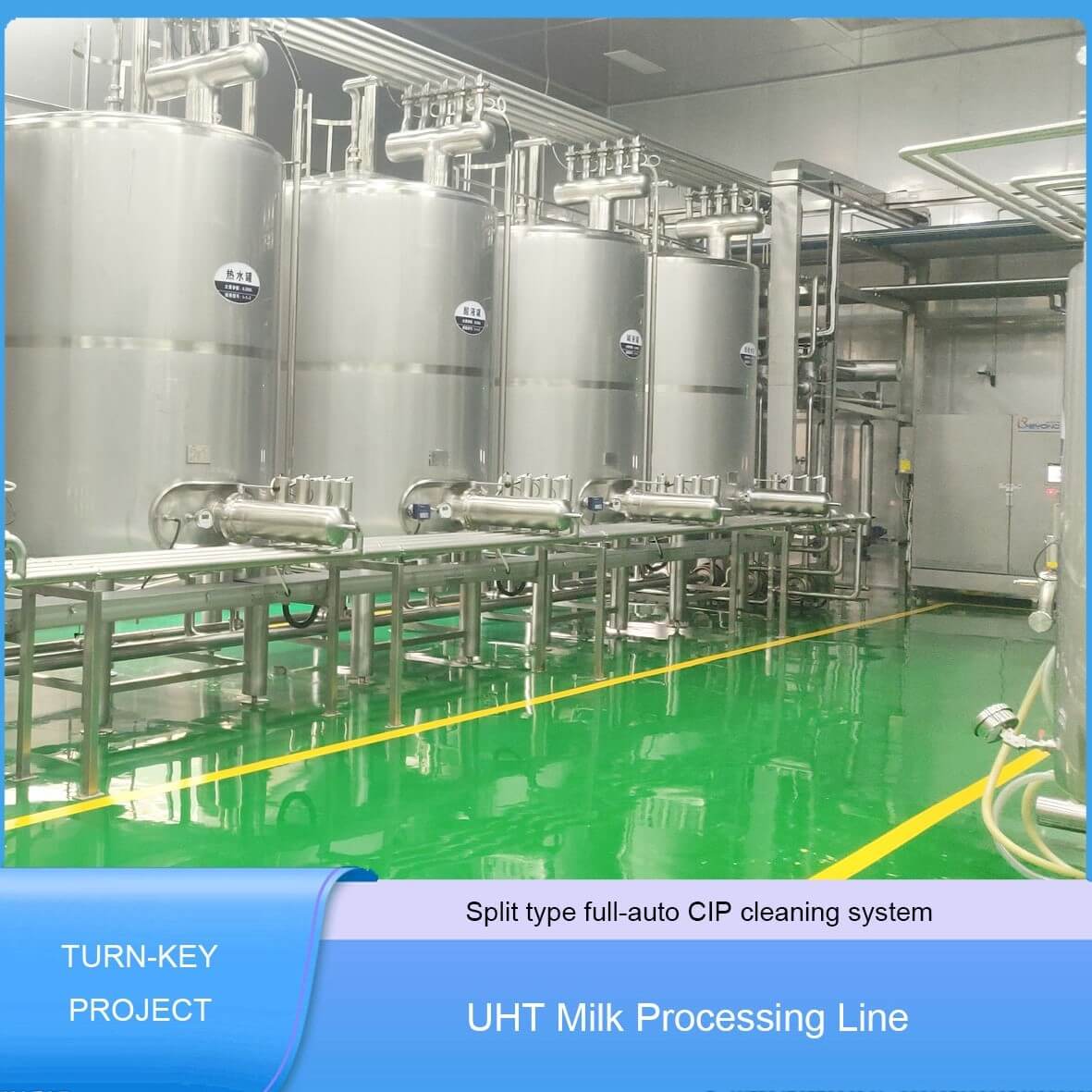

2. In terms of UHT Milk Processing Line, cleaning is a very important link. Different cleaning methods should be adopted for different equipment to meet the needs of UHT milk production.

a. Cleaning of batching equipment and pipelines. In order to avoid cross contamination, in principle, the batching tank is required to be cleaned every time it is emptied. The daily cleaning is mainly washing with clean water. If different varieties of products are prepared, it should be cleaned with 3% alkaline solution once in the middle, and high-temperature disinfection should be carried out every day.

b. Pipeline cleaning. The pipeline in front of the batching tank that only contacts the raw milk shall be cleaned every two times, with an interval of more than 1 h in summer and more than 2 h in winter, so as to prevent the residual milk in the pipeline from deteriorating and affecting the product quality. The best operation is to clean the raw milk in the pipeline with clean water after each milking, In this way, the waste of raw milk can be avoided and a good sanitary environment of the pipeline can be maintained. The pipeline connected with UHT equipment after batching tank can be cleaned together with UHT equipment.

3. CIP system cleaning.

CIP cleaning refers to the thorough closed cycle cleaning of UHT equipment. For neutral products, CIP cleaning shall be conducted for the equipment itself after continuous production for 8 hours. For acidic products or products with sterilization temperature of about 110 ℃, temperature alarm will not appear even after continuous production for 24 hours. Even so, the system of shutdown and cleaning within 24 hours shall be adhered to. Because UHT products are sterile products, no pollution is allowed. Only under the guarantee of the system can the quality and safety of products be guaranteed.