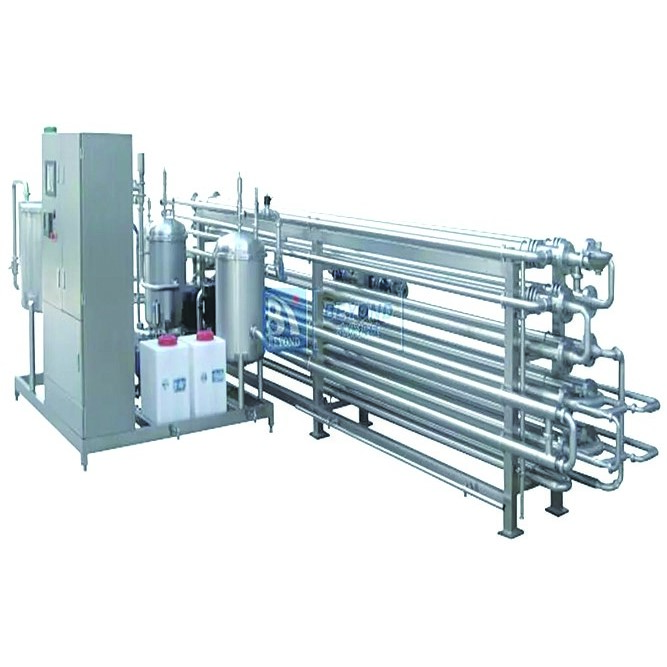

A fruit juice pasteurizer is a machine used to heat-treat fruit juices in order to kill harmful pathogens, extend shelf life, and maintain the nutritional value of the juice. The process of pasteurization involves heating the juice to a specific temperature for a certain period of time, typically between 160-185 degrees Fahrenheit (71-85 degrees Celsius). This helps to eliminate bacteria, yeast, and molds that can cause spoilage or illness.

Fruit juice pasteurizers often use technologies such as heat exchangers and steam injection to rapidly heat the juice and then quickly cool it down to prevent overcooking. The pasteurization process helps to preserve the natural flavor, color, and nutrients of the juice while ensuring its safety for consumption.

Some fruit juice pasteurizers are designed for small-scale operations, while others are large-scale industrial machines. They can be manual, semi-automatic, or fully automated, depending on the level of control and production volume required.

Overall, fruit juice pasteurizers play a crucial role in the commercial production of fruit juices, ensuring that they are safe and have an extended shelf life without compromising their quality.

Application

The fruit juice pasteurizer is mainly used for pre pasteurization of liquid products such as fruit pulp, fruit puree and fruit pulp. The normal working temperature is 55-90 ℃. The fruit pasteurizer can be used alone or integrated into the fruit processing line.

The fruit juice pasteurizer is specially used for fruit jam (tomato jam, mango jam, banana jam, peach jam, apricot jam, strawberry jam, pepper jam, etc.), concentrated fruit juice (apple juice, citrus juice, apple juice, pomegranate juice, etc.), pulp / granular fruit juice / jam, syrup and other high viscosity products.

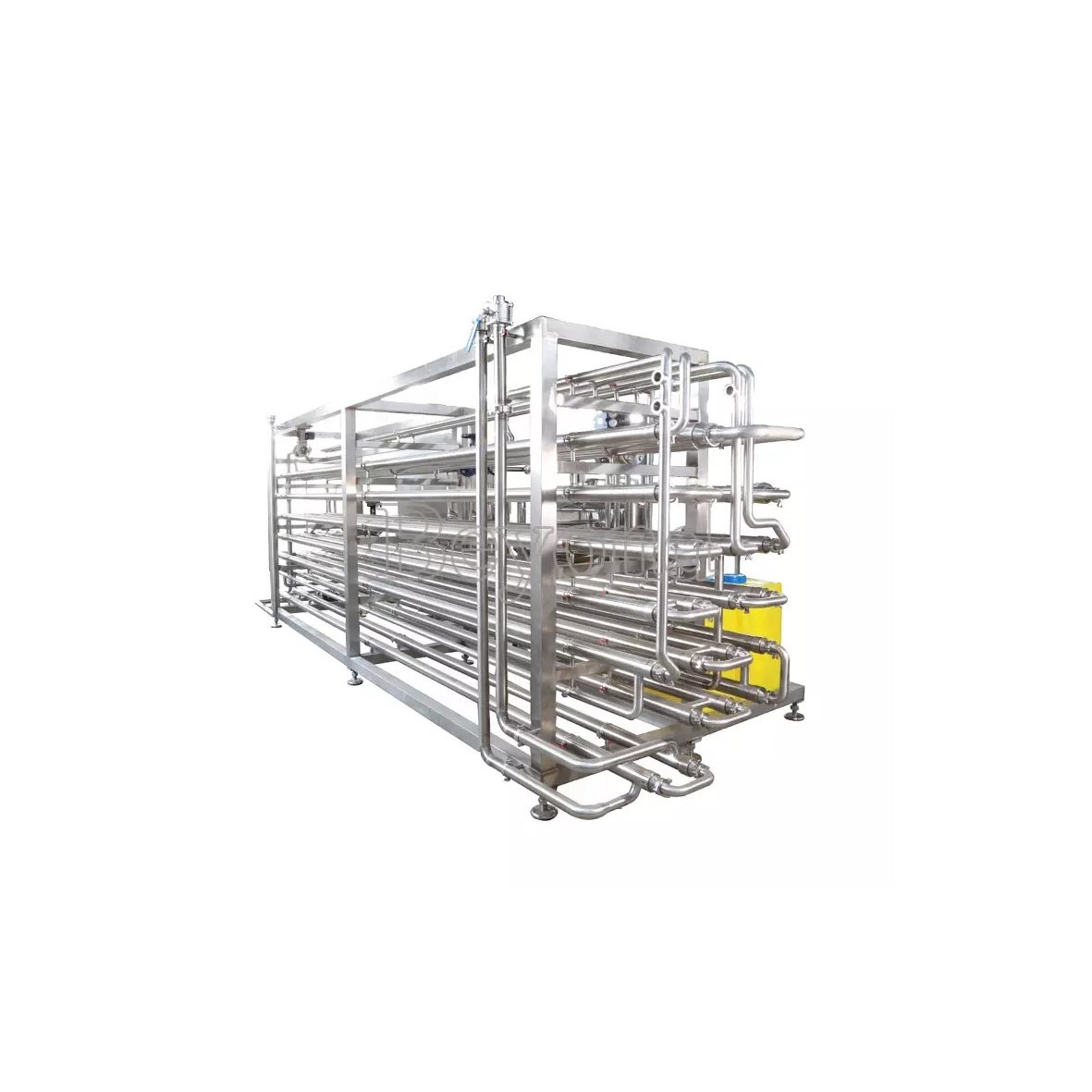

First, heat the product to the sterilization temperature with superheated water, and then keep it at this temperature for a period of time to thoroughly sterilize the product, and then cool it to the filling temperature with cooling water or with chilled water according to the processing requirements of the product. The heat exchange medium operates in the outer tube, and the product operates in the inner tube.

Suitable for heating liquid (tomato and fruit juice) and pasteurization.

It consists of tube in tube flow tubes for steam and products

The steam inlet is equipped with a pneumatic valve controlled by a temperature indicator.

The temperature can be adjusted from 50 ° C to 150 ° C.

The sterilization equipment heats the juice to the sterilization temperature, keeps it within the required time, and then cools it to the filling temperature.

The material in contact with the liquid is 316 stainless steel.

The preheater includes condenser discharge and steam connection pipe.

-Single tube heat exchanger.

Fruit juice pasteurizer is used for products that must be kept in solid suspension, or for products with high viscosity but easy to process. You can make smooth, wavy, or texture types.

-Multi tube heat exchanger.

The fruit juice pasteurizer is applicable to all cases where the product to be processed has no specific problems in terms of size, uniformity or viscosity, because they are the most advantageous from an economic point of view. You can make smooth, wavy, or texture types.

-Concentric tube heat exchanger:

Fruit juice pasteurizer is used to obtain high cooling and heating speed in high viscosity products. These products have no problem with suspended solid blocks. You can make smooth, wavy, or texture types.

-Scratched surface heat exchanger.

Fruit juice pasteurizer is absolutely the most flexible and indispensable for some products. For example, if you think the products tend to stick to the wall or are of different quality. They let solid fragments of considerable size through.

The fruit juice pasteurizer adopts the full-automatic PLC control system, man-machine interface operation and manual buttons as backup, so as to monitor and control the operation of the whole system online.

Procedures technical: 25℃→95-121℃(120S-180S)→25℃-35℃, the final

products can be filled in aseptic big bags for room temperature storage;

Compared to the other model, this machine has the following characteristics:

1.Temperature difference between the product and the heating medium is small, so the heating is gentle; the heating tubular adopts tube in tubes type and the surface of the tube is mirror polished to reduce the deposition on the surface which will longer the working life of the machine.

2. It is of high degree automatic, can automatically control the CIP cleaning, self sterilizing, and the whole procedures steps; all the procedures are recorded and controllable.

3. It is of precise and reliable sterilizing temperature control; all the affecting factors such as steam pressure, steam flow rate, product flow rate are all controllable;

4. The inside of the tubular adopts advanced polish procedure, all tubes can perform fully cleaning, self sterilizing ensures the system at aseptic state;

5. The system is strong safety, the fittings all adopts reliable materials.

6. The system is of high reliable, main parts such as product pump, hot water pump, all kinds of valves, elements of the electrics are all of world known brands.

7. With self SIP system.

Full automatic control: Spirax sarco reducer valve from UK, German Burkert & Spirax sarco temperature control system, German Labom temperature transducer, yuanan pipes and valves from shanghai , hot water pump from Italy, siemens LOGO touch-screen and PLC full automatic control, the precision of temperature control is ±0.5 degree, with self CIP and SIP system.

|

Model |

TG-UHT-1.5 |

TG-UHT-3 |

TG-UHT-5 |

|

Capacity(L/H) |

1500 |

3000 |

5000 |

|

Product inlet temperature(℃) |

25℃-40℃ |

25℃-40℃ |

25℃-40℃ |

|

Warm keeping time(S) |

120-180 |

120-180 |

120-180 |

|

Sterilization temperature(℃) |

95~121℃ |

95~121℃ |

95~121℃ |

|

Product outlet temperature(℃) |

25℃-35℃ |

25℃-35℃ |

25℃-35℃ |

|

Cooling water inlet(℃) |

≤30℃ |

≤30℃ |

≤30℃ |

|

Steam pressure |

0.5MPa |

0.5MPa |

0.5MPa |

|

Steam consumption |

~150Kg/h |

~210Kg/h |

~280Kg/H |

|

Compressed air pressure |

0.6MPa |

0.6MPa |

0.6MPa |

|

Compressed air consumption |

50L/H |

50L/H |

60L/H |

|

External dimension |

7000×2000×2000 |

7000×2000×2000 |

7000×2000×2200 |

|

Total weight |

1700kg |

2000Kg |

22 |

The fruit juice pasteurizer can be customized according to customers' needs, so that customers' use needs can be fully met, and the maximum use benefit can be obtained with the least equipment investment. Our customers of fruit pasteurizer are all over the world. They have achieved expected success in different industries.