A tomato processing production line is a series of machines and equipment used to process tomatoes into various products such as tomato paste, tomato sauce, diced tomatoes, or ketchup. The production line typically consists of several stages, including washing, sorting, chopping, cooking, and packaging.

Washing: The tomatoes are first washed to remove dirt and impurities. This can be done using water jets or by immersing the tomatoes in a water bath.

Sorting: The washed tomatoes are then sorted based on their size and quality. This is typically done using conveyor belts and sensors that detect any defects or foreign objects.

Chopping: The sorted tomatoes are then chopped into smaller pieces. This is usually done using a machine called a tomato crusher or pulper, which crushes the tomatoes and separates the skin and seeds from the pulp.

Cooking: The tomato pulp is then cooked to remove excess water and enhance its flavor. This is typically done in large steam-jacketed kettles or continuous cookers. The cooking process may also involve adding other ingredients such as sugar, salt, or spices to create different products.

Straining: After cooking, the tomato pulp may be strained to remove any remaining solids or impurities. This can be done using a centrifugal strainer or a sieve.

Concentration: In some cases, the tomato pulp may be further concentrated to increase its thickness and flavor. This is typically done using vacuum evaporators or rotary evaporators, which remove water from the pulp through evaporation.

Packaging: The final step of the tomato processing production line is packaging. The processed tomato products are typically filled into cans, bottles, or pouches. Automatic filling machines are often used for this purpose.

Labeling and Sealing: Once filled, the containers are labeled with product information such as the brand name, expiry date, and nutritional facts. They are then sealed to ensure product safety and freshness.

Quality Control: Throughout the production line, quality control measures are implemented to ensure that the processed tomato products meet the required standards. This may involve regular testing for parameters such as acidity, viscosity, color, and taste.

Storage and Distribution: The packaged tomato products are then stored in warehouses or refrigerated facilities before being distributed to retailers or customers.

Overall, a tomato processing production line is designed to efficiently process and transform fresh tomatoes into various value-added products for consumption.

Packing lines can be offered depending upon the requirement like Product in glass bottles, Cans, Drums, etc. Manufacturing process involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators. Evaporation plants are versatile in nature and can concentrate other juices also.

Features and benefits

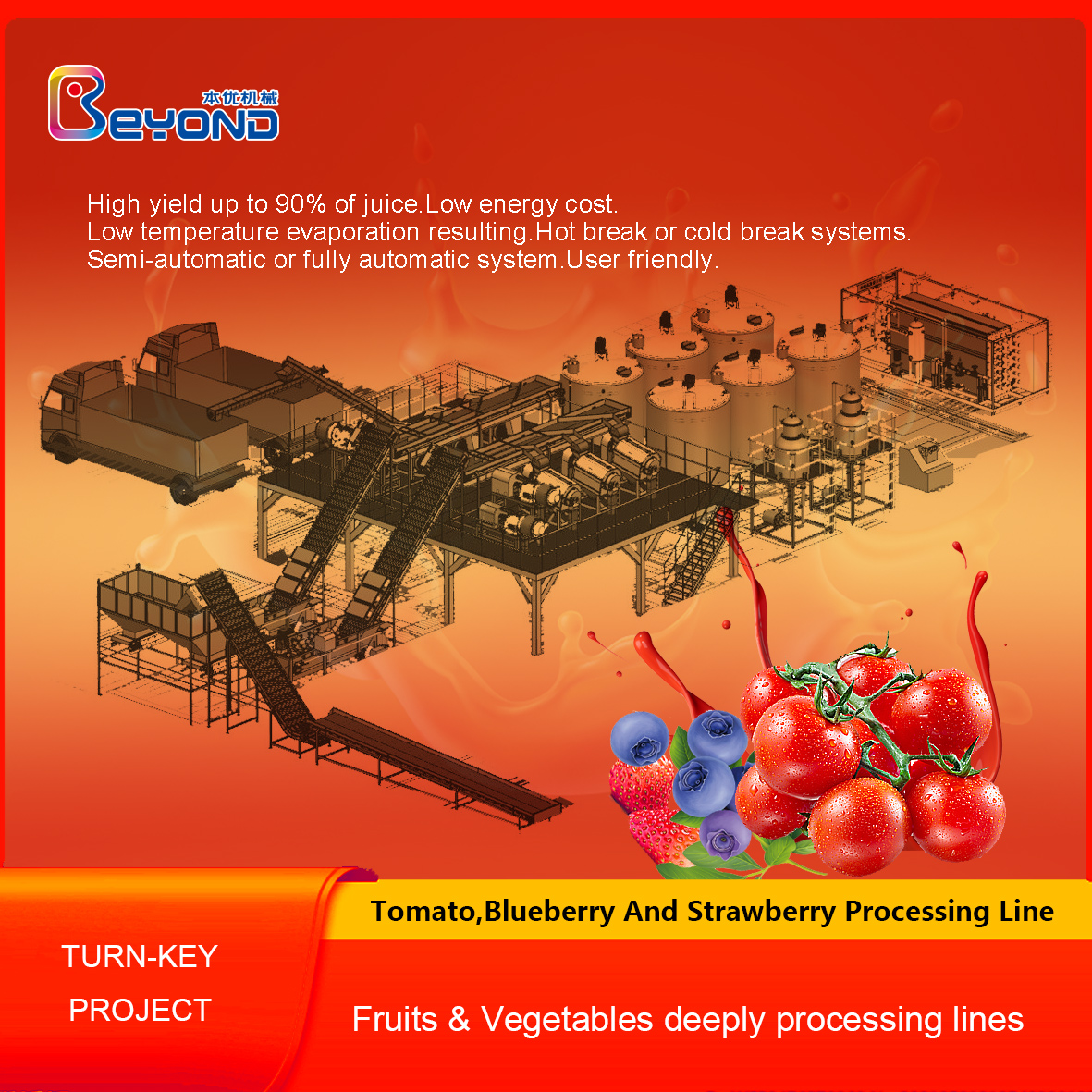

Our range of technologically advanced tomato processing solutions is designed to minimize downtime and maximize operational efficiency while respecting the highest safety standards and improving the quality of final products.

We are committed to providing targeted solutions, optimizing the functions of your production line and ensuring that your products and processes surpass competitors. Our extensive collection of tomato processing equipment ensures that:

High quality juice preparation - beyond's advanced enzyme treatment method produces tomato juice that meets the highest quality and taste standards.

Advanced paste production - our state-of-the-art evaporator is designed to consistently improve paste quality by reducing holding time, maintaining low temperature, improving circulation speed and reducing water and steam consumption.

Excellent paste sterilization - beyond sterile flash cooler is designed according to strict technical standards. This ensures better color, higher concentration consistency, lower energy consumption, less maintenance, longer operation time, and higher flexibility and customization.

Efficient evaporation - all beyond evaporators are designed to produce the highest quality ketchup on the market and maintain the sensory characteristics of fresh fruit; Multi effect design can also save energy and reduce operating costs.

The most advanced fruit juice refining technology - our variable speed turbine Juicer professionally separates tomato skin and seeds from fruit pulp to extract and refine fruit juice; The juicer can adjust the juice level in the process of juices.

Advanced aseptic filling machine - beyond's various single head and double head filling machines can choose to fill different types of aseptic bags.

Customizable and intuitive control system - our control system provides the most advanced support network and formula driven touch screen interface in the market; The system allows the processor to remotely control its devices and access beyond support directly from smart devices.

Professional after-sales technical support - in addition to the top machines we develop, we also provide comprehensive after-sales support, including technical services and spare parts.

Excellent processing and excellent product quality

Our range of tomato processing equipment is designed to maximize efficiency, yield and convenience while minimizing unnecessary energy, time and money expenditures. Our solutions achieve these specific goals without sacrificing any aspect of the final product quality. The juice, jam or puree you produce using our technology and equipment will meet the highest standards of appearance, taste and freshness.

Production line machine composition:

fruit collecting and feeding;

tomato washing machine;

tomato sorting machine;

cold break tomato pulping machine;

tomato puree storage tank;

tubular tomato pre-heating machine ;

tomato refining machine;

tomato paste/sauce/ketchup evaporator;

tomato paste/ sauce/ketchup storage tank;

tomato paste/ sauce/ketchup sterilizer;

tomato paste/ sauce/ketchup aseptic filling machine.

Main equipment of tomato paste production line In order to ensure efficient, hygienic and high-quality products during the production of tomato paste, a series of professional equipment is required. The following are the main equipment and functions on the tomato paste production line:

1. Raw material pretreatment equipment

•Washing Machine

•Purpose: Remove dirt, impurities and pesticide residues from the surface of fresh tomatoes.

•Features: Use multiple cleaning methods such as bubbling and spraying to ensure thorough cleaning.

•Sorting Machine

•Purpose: Automatically sort tomatoes according to standards such as size, color, and shape, and remove unqualified fruits.

•Features: Equipped with an advanced image recognition system, it can sort quickly and accurately.

•Crushing Machine

•Purpose: Crush tomatoes into small pieces for subsequent processing.

•Features: Made of stainless steel to prevent contamination; sharp knives and good crushing effect.

2. Blanching and peeling equipment

•Scalding Machine

•Purpose: Soften the peel and destroy the enzyme activity in the pulp tissue through short-term treatment with high-temperature steam or hot water.

• Features: Adjustable temperature and time to ensure the best processing effect.

• Peeling Machine

• Purpose: Remove the peel by mechanical or chemical methods to improve product purity.

• Features: High efficiency, environmental protection, suitable for large-scale production.

3. Pulping and Concentration Equipment

• Pulping Machine

• Purpose: Further crush the peeled tomatoes into a uniform pulp.

• Features: Double screw extrusion design to ensure high pulping rate and no large particles remain.

• Evaporator

• Purpose: Remove excess water by evaporation to make the tomato pulp reach the required solid concentration (usually 24%-30%) to form a thick tomato paste.

• Features: Multi-effect evaporation technology, energy-saving and efficient, reducing energy consumption.

4. Homogenization Equipment

• Homogenizer

• Purpose: Make the particles in the tomato paste more delicate, uniform in texture, and smooth in taste.

• Features: High-pressure homogenization technology to ensure stable product quality.

5. Sterilization and packaging equipment

•Sterilization Machine

•Purpose: Use high temperature instantaneous sterilization (HTST) or ultra-high temperature instantaneous sterilization (UHT) technology to ensure product safety and hygiene.

•Features: High degree of automation, reliable sterilization effect, and compliance with food safety standards.

•Filling Machine

•Purpose: Quantitative filling of sterilized ketchup into containers.

•Features: High precision, fast speed, and adaptable to various packaging forms (such as cans, bags, and boxes).

•Capping/Sealing Machine

•Purpose: Seal the filled containers to ensure the safety of the products during storage and transportation.

•Features: Automated operation, firm sealing, and good leak-proof performance.

6. Auxiliary equipment

•Conveyor Belt

•Purpose: Used for the transmission of materials between different processes.

•Features: Simple structure, smooth operation, easy to clean and maintain.

• Storage Tanks

• Purpose: To store semi-finished or finished tomato paste for easy mixing and supply.

• Features: Made of food-grade materials, corrosion-resistant, and large capacity.

• Cooling System

• Purpose: To cool the processed tomato paste to prevent high temperature from affecting the quality.

• Features: Circulating water cooling or air cooling, high cooling efficiency, low energy consumption.

7. Quality Control and Testing Equipment

• Online Testing Instruments

• Purpose: To monitor various parameters in the production process in real time (such as temperature, humidity, pH value, solid content, etc.).

• Features: Accurate data, quick response, and ensure stable product quality.

• Laboratory Testing Equipment

• Purpose: To inspect the quality of finished products, including microbiological testing, physical and chemical index analysis, etc.

• Features: Equipped with advanced testing instruments to ensure product safety and compliance.

Raw materials and products of tomato paste production line

I. Main raw materials

1. Fresh tomatoes

• Variety selection: Tomato varieties suitable for processing are usually high solid content, bright color, and rich flavor, such as San Marzano, Roma, etc.

• Quality requirements: The fruit should be moderately mature, free of pests and mechanical damage, with appropriate water content and reasonable sugar-acid ratio to ensure the quality of the final product.

2. Water

• Use: Used to wash tomatoes and balance the water required in the concentration process.

• Quality requirements: It must meet the drinking water standards, the water quality must be clean, odorless, and free of any harmful substances.

3. Food additives (added as needed)

• Preservatives: such as potassium sorbate, etc., used to extend the shelf life of the product.

• Seasonings: such as salt, spices, etc., adjust the flavor according to the specific formula.

• Antioxidants: such as vitamin C, etc., to prevent the product from oxidizing and discoloring, and maintain the color and taste.

2. Final product - tomato paste

• Appearance: dark red to reddish brown, high viscosity, uniform texture, no obvious granularity.

• Taste: rich tomato flavor, moderate sweetness and sourness, with natural delicious taste.

• Nutritional ingredients:

• Vitamin C: rich antioxidant, helps to enhance immunity.

• Lycopene: a powerful antioxidant, good for cardiovascular health.

• Minerals: such as potassium, magnesium, etc., to maintain electrolyte balance in the body.

• Dietary fiber: promotes digestive health.

water consumption

180-250 t/h( inlet temperature: 32℃;outlet temperature:38℃)

Tomato Juice Processing Key Operational Points

Fresh Tomato pretreatment

The system is including the cleaning and sorting of fresh tomatoes,crushing them into 3-5mm tomato pieces,and then preheating them through a tubular preheater.The selection and cleaning process is of great significance to the quality and stability of the final tomato juice.The preheating and crushing processes are important processes that affect the consistency of tomato juice and the yield of juice.There are two crushing methods:hot break and cold break.Due to the low temperature of the cold-breaking sauce,the endogenous enzymes(mainly pectin tertiary enzymes)are not completely inactivated.The pectin is enzymatically hydrolyzed into short chains,and the viscosity will be low,but the flavor and color are good.The hot break enzyme is inactivated thoroughly,the pectin is less damaged,the viscosity is good,the flavor and color are poor.

Tomato squeezing and juicing

Squeeze the crushed fruit pulp after heating,while removing the peel and seeds,it also adjusts the pulp particles.Generally,it can be operated by a screw juicer or a beater.The screw juicer squeezes the crushed pulp between the screw and the sieve to extract the juice,and the beater extracts the juice by impact,and the aperture of the sieve is about 0.4mm.The squeezing rate of good varieties of tomato juice is 75%-80%。

Tomato juice blending and seasoning

As a seasoning for tomato juice,we can add wine vinegar,table salt,white sugar,lemon juice,etc.

Degassing,homogenization and sterilization of tomato juice

In the process of tomato crushing and blending,the air is inevitably mixed in,so after the juice is squeezed and blended,the tomato juice needs to be deaerated.At the same time,in order to refine the pulp particles and increase the consistency,a homogenizer can be used to make the tomatoes have a smooth feel through homogenization.Tomato juice contains pulp,which makes it a relatively viscous liquid.Therefore,it needs to be sterilized before filling.The HTST sterilization process is usually used(90-95℃ for 40-60S).The sterilized tomato juice is orange-red,the sugar content is 4.3%,and the PH value is 4.4.

Filling and sealing of tomato juice

The containers used for tomato juice are metal cans,glass bottles or PET bottles.The pre-sterilized tomato juice is filled into a clean container.In order to prevent oxidation,it is necessary to quickly cool the sterilized tomato juice to 85-89℃ and fill it into the container immediately.To prevent oxidation of the product,this filling method is called hot filling.It should be sealed immediately after filling.

Secondary pasteurization and packing of the tomato juice

After the filling is completed,for the sake of safety,the tomato juice needs to be sterilized twice,and the filled container is transported to the pasteurization tunnel or retort for secondary sterilization.The sterilization process is 90-95℃ for 15-20min.Then use cooling water to quickly cool the temperature of tomato juice to below 35℃ for subsequent packaging.

Innovate equipment to improve final product quality and operational efficiency, minimize downtime, and reduce capital investment to achieve higher profit margins.

Whether you are producing tomato juice, diced tomato, ketchup or mashed tomato, our advanced tomato processing solutions can meet the most challenging processing requirements today. With more than 50 years of experience in producing the highest quality system in the market, we continue to innovate and break through the limits of the industry, so that our customers can produce first-class final products, save time and eliminate unnecessary costs.

Customizing a tomato sauce production line is a complex and multi-step process that involves multiple stages such as raw material processing, processing, and packaging. Here is a detailed customized solution to help you plan and implement this project:

1. Requirement analysis

•

Product Objective: Determine the type of tomato sauce you wish to produce (such as regular tomato sauce, low salt tomato sauce, organic tomato sauce, etc.).

•

Production scale: Determine the daily or hourly production capacity.

•

Quality standards: Clarify the quality standards of the product, including taste, color, nutritional content, etc.

•

Market positioning: Determine the target market and consumer group of the product.

2. Process flow design

Raw material processing

•

Raw material receiving: Set up a raw material receiving area to ensure the freshness and hygiene of the raw materials.

•

Cleaning: Use a cleaning machine to remove dirt and impurities from the surface of raw materials.

•

Peeling: Use a peeling machine to remove tomato skins.

•

Seed removal: Use a seed removal machine to remove tomato seeds.

•

Chop: Chop the peeled and seeded tomatoes into small pieces for subsequent processing.

machining

•

Preheating: Use a preheater to heat chopped tomatoes, making them easier to process.

•

Beating: Use a beater to mash the heated tomatoes into a pulp.

•

Concentrate: Use an evaporator to concentrate the slurry to the desired concentration, forming tomato sauce.

•

Sterilization: Use sterilization equipment to sterilize concentrated tomato sauce at high temperatures to ensure food safety.

•

Cooling: Cool the sterilized tomato sauce to a suitable temperature.

packing

•

Filling: Use a filling machine to fill tomato sauce into bottles or bags.

•

Sealing: Use a sealing machine to seal the packaging to ensure sealing.

•

Labeling: Use a labeling machine to attach labels to the packaging, indicating product information.

•

Packing: Pack the packaged tomato sauce into boxes and prepare for shipment.

3. Equipment selection

•

Raw material receiving area: conveyor belt, storage bin.

•

Cleaning machine: Bubble cleaning machine or spray cleaning machine.

•

Peeling machine: Efficient peeling machine.

•

Seed removal machine: an efficient seed removal machine.

•

Chopper: Multi functional chopper.

•

Preheater: Steam preheater or hot water preheater.

•

Beating machine: Efficient beating machine.

•

Evaporator: Vacuum evaporator or thin film evaporator.

•

Sterilization equipment: high-pressure sterilization pot or continuous sterilization line.

•

Cooling equipment: Plate heat exchanger or cooling tower.

•

Filling machine: Automatic filling machine.

•

Sealing machine: rotary sealing machine or heat sealing machine.

•

Labeling machine: automatic labeling machine.

•

Packing machine: Automatic packing machine.

4. Technical consultation and evaluation

•

Cost assessment: Evaluate the cost of equipment, including purchase cost, installation cost, operating cost, and maintenance cost.

•

Technical evaluation: Evaluate the technical performance of equipment to ensure that it meets production requirements and quality standards.

5. Scheme confirmation

•

Technical exchange: Conduct detailed technical exchanges with suppliers to confirm the specific configuration and technical details of the equipment.

•

Contract signing: Sign a contract with the supplier to clarify the rights and obligations of both parties.

6. Production and manufacturing

•

Production preparation: The supplier prepares for production based on the confirmed plan, including raw material procurement, component processing, etc.

•

Assembly and debugging: After the equipment is assembled, preliminary debugging is carried out to ensure the normal operation of each component.

7. Installation and debugging

•

On site installation: Transport the equipment to your factory for on-site installation.

•

System debugging: Debugging the entire production system to ensure smooth operation of every link.

•

Performance testing: Conduct performance testing to ensure that the equipment achieves the expected production efficiency and product quality.

8. Training and Acceptance

•

Operation training: The supplier provides training to your operators to ensure they are proficient in operating the equipment.

•

Equipment acceptance: Conduct a comprehensive acceptance of the equipment to ensure that it meets the technical requirements and performance indicators stipulated in the contract.

9. Post service

•

Technical support: Suppliers provide necessary technical support to solve problems that arise during equipment operation.

•

Maintenance and upkeep: Regularly maintain and upkeep equipment to extend its service life.

Matters needing attention

•

Regulatory compliance: Ensure that the design and production of equipment comply with local food safety regulations and standards.

•

Environmental protection: Consider the environmental performance of equipment and reduce the discharge of wastewater and exhaust gas.

•

Safety measures: Ensure the safety performance of the equipment and prevent accidents during operation.

I hope the above plan can help you smoothly customize an efficient tomato sauce production line.