Mango processing line refers to a series of machinery and equipment used to process mangoes into various products such as mango pulp, mango puree, mango juice, dried mango slices, and mango jam.

The processing line typically includes the following steps:

Washing and sorting: Mangoes are initially washed to remove dirt and foreign matter. Then, they are sorted based on size and quality.

Peeling and destoning: Mangoes are peeled using a machine that removes the outer skin while minimizing flesh loss. Next, the stones or pits are removed using a destoning machine.

Cutting and slicing: Mangoes are cut into desired shapes and sizes, such as cubes or slices. This can be done manually or by using automated cutting machines.

Pulp extraction: The mango flesh is then processed to extract the pulp. This can be done through various methods, including pulping machines, which separate the pulp from the fibers and seeds.

Pasteurization: The extracted mango pulp is pasteurized to ensure safety and extend shelf life. This is done by heating the pulp to a specific temperature for a certain period of time.

Packaging: The processed mango pulp or other mango products are packaged in containers, such as cans, jars, or tetra packs, for distribution and sale.

Additional steps may be included depending on the specific product being produced. For example, if producing mango juice, the pulp may undergo further filtration to remove any remaining solids.

It's important to note that each processing line can be customized based on specific requirements and production capacities.

Characteristics of mango juice plant

1. The processing capacity is varied.

2. The line can deal with similar characteristic of fruits.

3. Using the high efficient of mango destoner to improve the mango output percentage effectively.

4. Using efficient belt juice extractor to improve the juice efficiency and the output percentage of pineapple.

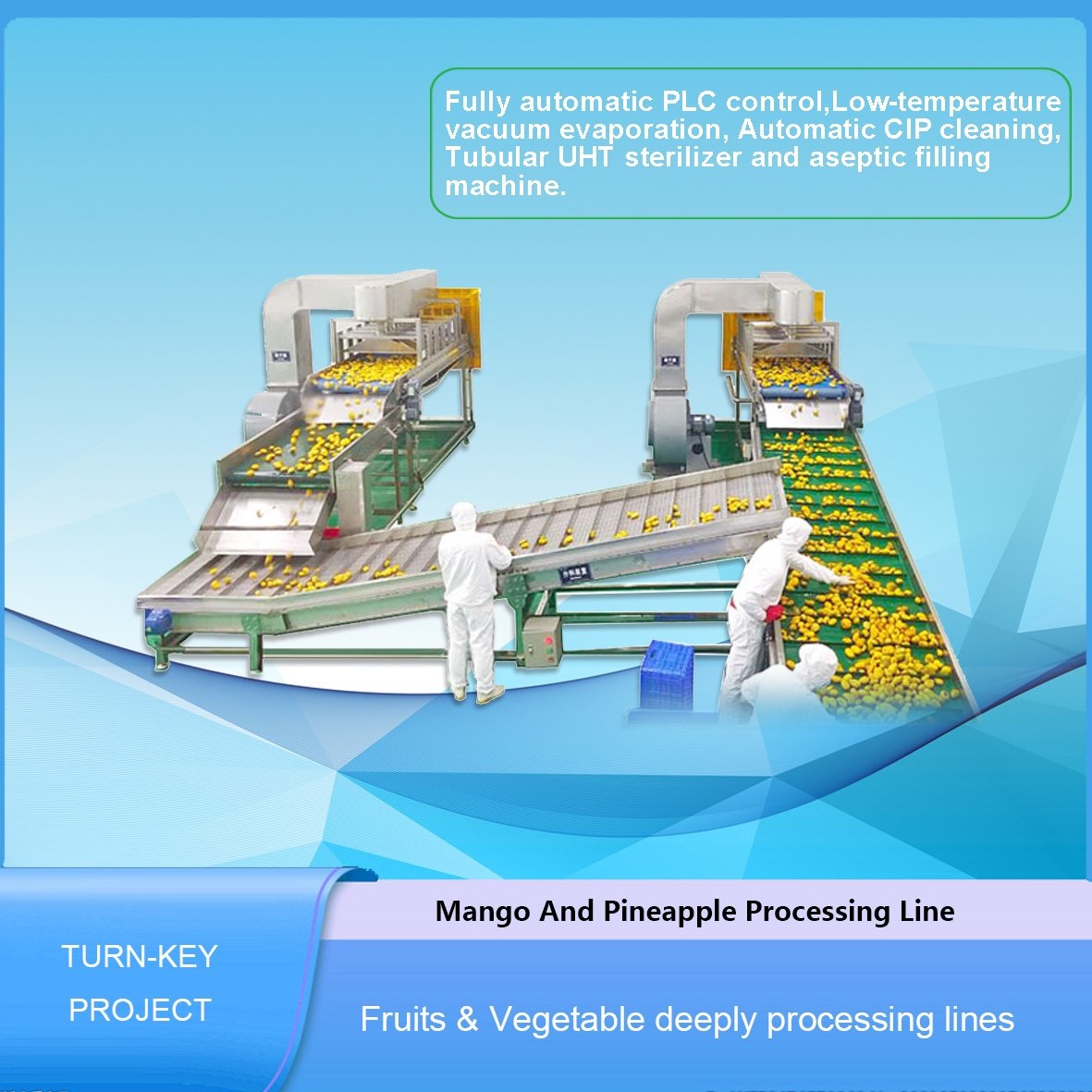

5. The production process fully automatic PLC control to save labor and facilitate production management.

6. Low-temperature vacuum evaporation, maximize reserve the flavor substances and nutrients also save energy.

7. Tubular UHT sterilizer and aseptic filling machine, produce high-quality aseptic juice products.

8. Automatic CIP cleaning, ensure the entire line equipment of food hygiene and safety requirements.

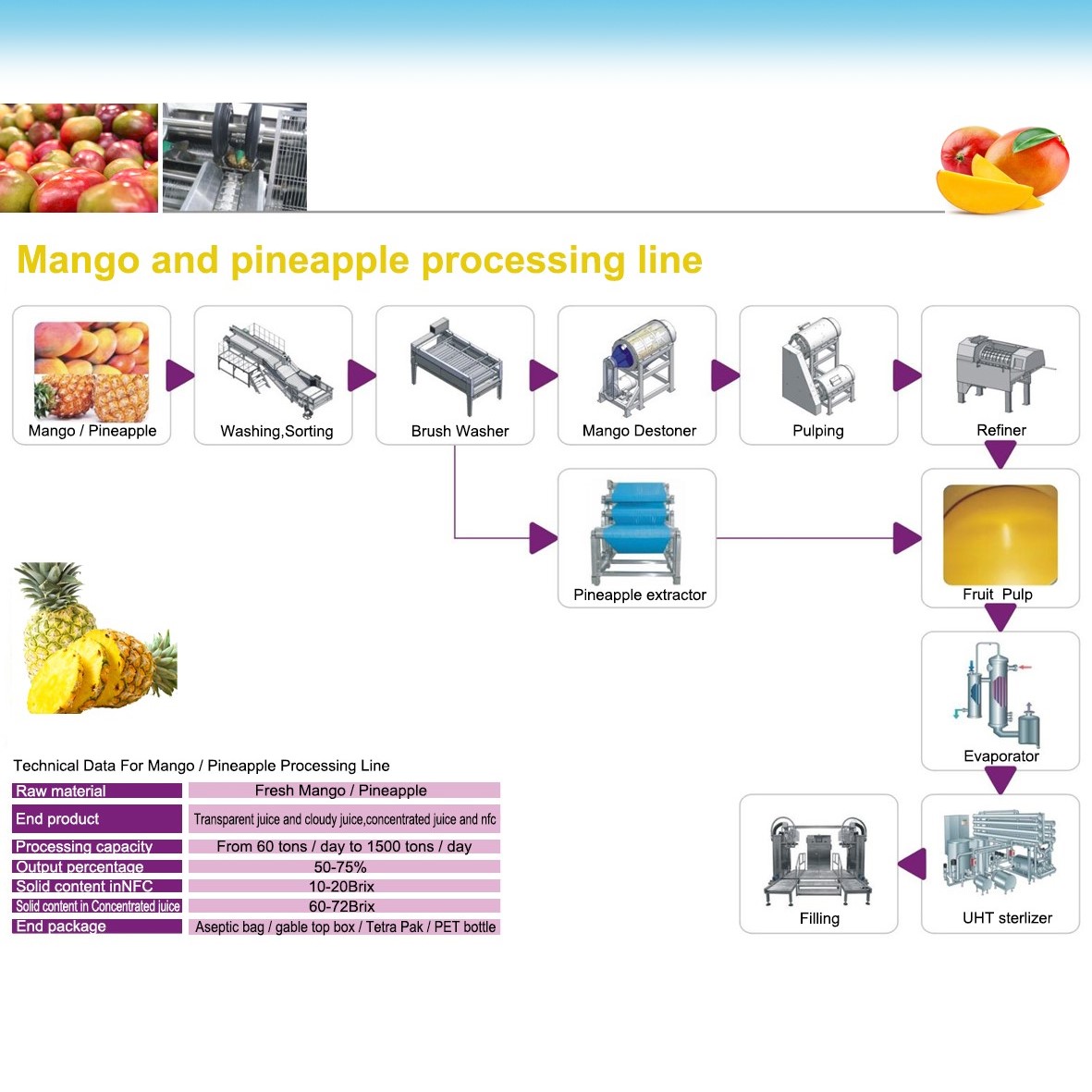

Raw material:

Mango and pineapple Peach,apricot,plum and other similar flesh fruits with hard seed

End product:

Nature Juice, juice Concentrate, transparent juice, cloudy juice, canned fruits

Production capacity:

20T/D-2000T/D

Output percentage:

≥90%

Solid content

7~12Brix

Packing type for end product:

Aseptic Bag/glass Bottle/PET Bottle /gable Top Box/Tetra Pak

The End Products and Packaging Containers

-Concentrated mango pulp/puree filled into aseptic bags in drums or bag in box containers.

-Non-concentrated mango pulp/puree filled into aseptic bags in drums or bag in box containers.

-Blended mango juice filled into PET/glass bottles,small tin cans,tetra paks,cartons,or other small containers.

-NFC mango juice filled into PET/glass bottles,aseptic cartons.

-Dry Mango chips/slice filled into pouches or jars.

The processing flowchart of the mango processing line

Concentrated mango pulp/puree flowchart

Fresh mango after washing,sorting,destoning and peeling,pulping filtering,evaporating,sterilizing then filled into 220kg aseptic bags in drums.

The end products of concentrated mango juice technical parameter is Brix 28-30% or 30-32%,PH value is 3.0-4.0.

Non-concentrated mango pulp/puree flowchart

Fresh mango after washing,sorting,destoning and peeling,pulping filtering,homogenizing,vacuum degassing,sterilizing then filled into 220kg aseptic bags in

drums.The end products of non-concentrated mango pulp/puree technical parameter is that Brix value is 14-22%,Total acidity:0.3-1.1%,PH:3.2-4.0,Pulp content:>40%.

Blended mango nectar/juice flowchart

Concentrated mango puree/juice are as raw materials,after blending with water and sugar and other additives,homogenizing and degassing,sterilizing,the end mango juice are filled into PET/glass bottles,small tin cans,aseptic cartons.

NFC mango nectar flowchart

The mango is washed,peeled,sliced and dried to make dried mango slices.It takes 20-30 hours to complete drying for each batch of fresh mangoes.The moisture of fresh mango slices is between 80%-85%.After being dried by a heat pump dryer,the moisture of dried mango slices is about 10%-12%.The heat pump drying is

completed in 5 stages:the first stage is 55℃,which is the heating stage,the second stage is 60℃,the dehumidification stage,the third stage is 62℃,the continuous dehumidification stage,the fourth stage is 58℃,cooling and dehumidifying,and the last stage 55℃,consolidate and dehumidify.

Concentrated mango pulp/puree filling machine

We have one head or double heads aseptic filler to fill the concentrated mango puree into 220kg aseptic bags in drums,the capacity is 1 ton per hour to 5 tons per hour.And the concentrated mango puree in aseptic bags has a long shelf life about 2 years in a cold environment.The aseptic bag filling machine is complete sanitation with CIP cleaning function,the mango puree filling is controlled by flowmeter with high precision,the filling chamber is sterilized by steam to ensure the aseptic conditions.

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

Energy consumption: Low consumption with high efficiency

Capacity: 500-10000L/H-customized

Installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

Related machinery of fruit processing line

Fruit storage silo-- Washing, sorting machine-- Grading/classifier machine

Squeeze extractor--Juice refiner—separator—evaporator-- Juice concentrate product

Fruit flesh/pulp collector-sterilizer--filling machine—fruit flesh

Essential oil refiner—fruit oil

Fruit residues collector—animal feed

Soaking extraction, pre-cooking, pulping, quick freeze, stemmer, ultra-filtration, decolor, destoner, crusher, stone washer, brusher washer, pine apple extractor, refiner, enzymolysis, filtration, CIP cleaning system

The process of customizing a Mango Processing Line typically involves the following steps to ensure that every step from requirement analysis to final delivery meets the customer's requirements. The following is the detailed customization process:

1. Requirement analysis

• Preliminary communication: Conduct preliminary communication with customers to understand their specific needs and expectations, including production scale, product types, quality requirements, etc.

• Requirement research: Through questionnaire surveys, on-site inspections, and other methods, gain a deep understanding of the customer's production environment, mango varieties, and processing technology requirements.

2. Scheme design

Preliminary plan: Based on the results of demand analysis, design a preliminary production line plan, including equipment selection, layout design, control system, etc.

Technical exchange: Conduct technical exchanges with clients to confirm the feasibility of the plan and make necessary adjustments.

3. Quotation and Contract Signing

• Detailed quotation: Provide a detailed equipment list, prices, and delivery time.

Contract signing: After both parties confirm that there are no errors, a formal contract will be signed.

4. Design and Manufacturing

• Detailed design: Conduct detailed design work according to contract requirements, including mechanical design, electrical design, control system design, etc.

Production and manufacturing: produce and assemble equipment according to design drawings and process requirements.

5. Installation and commissioning

Equipment transportation: safely transport production equipment to the customer's site.

Installation and debugging: Install and debug the equipment on site to ensure the normal operation of all parts.

Performance testing: Conduct comprehensive performance testing on the production line to ensure that the expected results are achieved.

6. Training and Acceptance

• Operation training: Provide equipment operation and maintenance training to customers' operators.

Acceptance and delivery: The customer conducts a final acceptance of the production line, confirms its accuracy, and officially delivers it for use.

7. After sales service

• Technical support: Provide continuous technical support and consulting services.

• Regular maintenance: Regularly maintain the production line to ensure long-term stable operation.

Matters needing attention

Frequent communication: Maintain frequent communication with customers throughout the entire customization process and promptly resolve any issues that arise.

Quality control: Strictly control the quality of each link to ensure the reliability of the final product.

Flexible adjustment: Based on customer feedback and actual situation, adjust the plan flexibly to ensure that customer needs are met.

Through the above process, Shanghai Beyond Machinery can provide customers with high-quality and efficient mango processing production lines, helping them achieve production automation and intelligence.