Description of Peach / Apricot and Plum Processing Line

A peach, apricot, and plum processing line is a system designed to wash, sort, and process these fruits for various end products such as jams, juices, canned fruits, and dried fruits. The line typically consists of several machines and equipment that perform specific tasks in the processing process. Here are the common steps involved in a peach, apricot, and plum processing line:

Washing: The fruits are initially subjected to a washing machine to remove any dirt, dust, and other impurities. This ensures the cleanliness of the fruits before further processing.

Sorting: After washing, the fruits are sorted based on their size, color, and quality. A sorting machine is used to separate the fruits into different categories, ensuring only the best quality ones proceed to the next step.

Pitting/De-stoning: In this step, the fruits are pitted or de-stoned to remove the seeds. This can be done using a specialized machine that cuts the fruits open, removes the pit, and separates the flesh.

Slicing/Dicing: Once pitted, the fruits can be sliced or diced depending on the desired end product. Slicing machines can cut the fruits into uniform slices or dicing machines can chop them into smaller pieces.

Cooking/Boiling: The sliced or diced fruits are then cooked or boiled to soften them and enhance flavor. This step is crucial for making jams, jellies, or preserves.

Blending/Pureeing: Some applications may require blending or pureeing the cooked fruits to achieve a smooth texture. This is commonly done for fruit sauces, fillings, or baby food products.

Packaging: The final processed fruits are packaged into suitable containers such as jars, bottles, cans, or pouches. This step may involve automatic filling and sealing machines to ensure proper packaging and preservation.

Pasteurization/Sterilization: Depending on the intended shelf life and safety requirements, the packaged fruits may undergo pasteurization or sterilization processes. This helps extend the product's lifespan and prevents spoilage.

Cooling/Freezing: After pasteurization or sterilization, the packaged fruits are cooled down to room temperature or frozen depending on the storage requirements. This step ensures the products are safe for transportation and future consumption.

Labeling and Quality Control: Finally, the packaged fruits are labeled with necessary information such as ingredients, nutritional facts, and expiry dates. Quality control checks are performed to ensure that the products meet the desired standards and specifications.

Throughout the processing line, various conveyors, pumps, and control systems are integrated to streamline the flow of fruits and ensure efficient production. The specific configuration and capacities of the machines can vary depending on the scale of the processing line and the desired output.

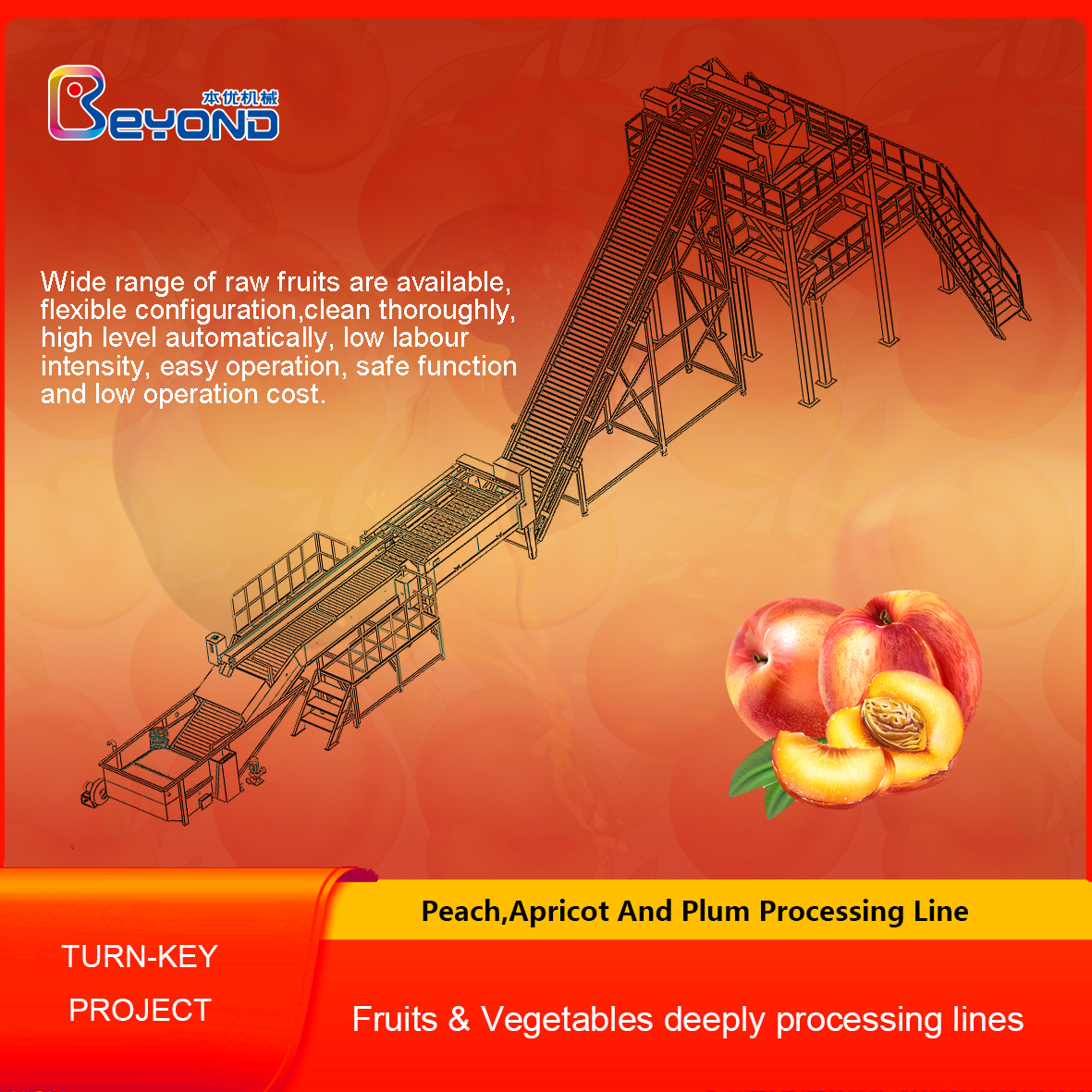

Characteristics of peach, apricot, plum and other similar fruits processing line

1. Wide range of raw fruits are available, this line is applicable for all kinds of hard seed fruits with pulp, such as peach, apricot, plum etc.

2. Flexible configuration to make this line, according to different requirements of the end products, some exact equipments with different functions are flexible chosen, for example: enzymolysis, evaporation etc.

3. According to different investment and product structure prefered, client can require average, middle level or high level processing equipments.

4. End product with pure flavor, bright colour, and high juice output percentage;

5. Whole line with features as high level automatically, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can clean thoroughly, with high level sanitation.

Technical data :

|

Raw material: |

Peach,apricot,plum and other similar flesh fruits with hard seed |

|

End product: |

Nature Juice, juice Concentrate, transparent juice, cloudy juice, canned fruits |

|

Production capacity: |

20T/D-2000T/D |

|

Output percentage: |

≥90% |

|

Solid content |

7~12Brix |

|

Packing type for end product: |

Aseptic Bag/glass Bottle/PET Bottle /gable Top Box/Tetra Pak |

Apricot,Plum&Peach Processing Line End Products And Package

-Concentrated apricot,peach and plum puree:30-32 brix,PH value is 4.0-4.8,packed into 220kg aseptic bags in drums.The raw concentrated puree can be made into juices,beverages and baby food purees.The shelf life is 2 years stored into below 20℃.

-Single strength apricot,peach and plum puree:10-12brix,it can be packed into small pouches,bottles for direct consumption.

-Apricot,peach and plum juice:Use fresh fruits or concentrated puree to blend with water and other ingredients to make into juice and fill into small bottles or metal cans.

-Apricot,peach and plum fruit chips:Fresh fruits after washing,sorting,then cut the fruits into slices or pieces,after that use the pump dryer or belt dryer to remove the water and make them into 10%-12% water content dry fuit slices and filled into bags.

Apricot,Plum And Peach Processing Line Technological Flowchart

Using fresh and ripen Apricot,peach and plum fruits as raw material,then use one air bubble washing machine and brush washer to remove the foreign matters on fruits,then sort out the bad and unripe fruits out manually,now we get the high-quality clean fruits.After that,we use one fruit pitting machine to remove the fruit stones,and we will get the crushed fruits,To increase the puree yield rate,we can use one tubular preheater to inactivate enzymes in fruits,then the double stage pulping machine is used to make them into fruit puree.But there are still some coarse solids or inedible crude fiber after pulping machine,to remove them,we use one decanter centrifuge separator.Until this process,we obtain the fine fruit puree.The evaporator can be used to make into concentrated puree and after sterilization,it can be filled into aseptic bags,the single strength puree can also be homogenized,pasteurized and filled into small pouches.

Apricot,peach and plum washing and sorting machine

Apricot,peach and plum fruits are received in the bubble washing machine where,by immersion in the water and thanks to a buble generating system,the surface of the fruits is washed.Fruits are then rinsed by a shower of fresh water on the elevator that takes the fruits to the sorting operations.Waste and sand sink to the bottom and are discharged by our special design.

In order to guarantee the best quality of the final products,rotten and unripe fruits must be discarded.Universal sorting line allows to efficiently inspect the fruits,by making them slowly rotate on a roller belt conveyor under the sight of the operators.The machine is equipped with waste conveying system,discharging the waste away.

Apricot,peach and plum pitting machine and pulping machine

The destone machine is fitted for pitting peaches,plums,apricots has a capacity of up to 10 Tons/H of fresh fruit and it is capable of processing also hard and large fruits without severe losses in yield.

For a perfect separation of the puree from pitted fruits,the fruit pulping machine is adopted.The machine can be equipped with an inverter,which is suitable to adjust the rotation speed and with an inert gas injection device,for protecting product against oxidation.Rotating speed can go as 1470r/min,which generates large centrifugal force and helps increase the juice yield,and the puree yield rate is from 65%-75% according to fruit variety.

Apricot,peach and plum puree evaporator

To get the concentrated puree,we use the force circulation evaporator to remove water in puree,after concentration,the puree is about 2.5 times higher solid than single strength puree.The whole evaporation process is in low temperature to keep the natural ingredients in fruits to the most extend.And the steam,cooling water can be recycled when evaporator works,saves a lot of energy.

Apricot,peach and plum puree sterilizer

Apricot,peach and plum puree can be sterilized by the tubular sterilizer.At this stage,all microorganisms are destroyed.In contrast to the stage of preheating,sterilization takes place at higher temeratures(95℃-115℃).The specific value of sterilizing temperature is set depending on the technical nuances of each particular production.

Apricot,peach and plum puree filler

The concentrated puree can be filled into aseptic bags in drums or bags in box,whereas the single strength puree can be filled into small pouches for baby food consumption.

Customizing a peach juice processing equipment is a complex process that involves multiple steps and technical considerations. The following is a general customization process that can help you better understand and plan for this process:

1. Requirement analysis

•

Product objective: Determine the type of peach juice you wish to produce (such as pure fruit juice, concentrated fruit juice, low candy juice, etc.).

•

Production scale: Determine the daily or hourly production capacity.

•

Quality standards: Clarify the quality standards of the product, including taste, color, nutritional content, etc.

•

Market positioning: Determine the target market and consumer group of the product.

2. Design proposal

•

Preliminary design: Based on requirement analysis, design a preliminary equipment plan, including equipment layout, main functional modules, etc.

•

Technical parameters: Determine the technical parameters of the equipment, such as power, size, material, etc.

•

Process flow: Design a detailed production process flow, including raw material pretreatment, juice extraction, filtration, sterilization, filling and other links.

3. Technical consultation and evaluation

•

Supplier selection: Choose experienced equipment suppliers for technical consultation to understand the strengths and weaknesses of different suppliers.

•

Cost assessment: Evaluate the cost of equipment, including purchase cost, installation cost, operating cost, and maintenance cost.

•

Technical evaluation: Evaluate the technical performance of equipment to ensure that it meets production requirements and quality standards.

4. Scheme confirmation

•

Technical exchange: Conduct detailed technical exchanges with suppliers to confirm the specific configuration and technical details of the equipment.

•

Contract signing: Sign a contract with the supplier to clarify the rights and obligations of both parties.

5. Production and manufacturing

•

Production preparation: The supplier prepares for production based on the confirmed plan, including raw material procurement, component processing, etc.

•

Assembly and debugging: After the equipment is assembled, preliminary debugging is carried out to ensure the normal operation of each component.

6. Installation and debugging

•

On site installation: Transport the equipment to your factory for on-site installation.

•

System debugging: Debugging the entire production system to ensure smooth operation of every link.

•

Performance testing: Conduct performance testing to ensure that the equipment achieves the expected production efficiency and product quality.

7. Training and Acceptance

•

Operation training: The supplier provides training to your operators to ensure they are proficient in operating the equipment.

•

Equipment acceptance: Conduct a comprehensive acceptance of the equipment to ensure that it meets the technical requirements and performance indicators stipulated in the contract.

8. Post service

•

Technical support: Suppliers provide necessary technical support to solve problems that arise during equipment operation.

•

Maintenance and upkeep: Regularly maintain and upkeep equipment to extend its service life.

Matters needing attention

•

Regulatory compliance: Ensure that the design and production of equipment comply with local food safety regulations and standards.

•

Environmental protection: Consider the environmental performance of equipment and reduce the discharge of wastewater and exhaust gas.

•

Safety measures: Ensure the safety performance of the equipment and prevent accidents during operation.