In the global landscape of industrial food processing, pasteurization machines have emerged as indispensable tools, safeguarding the quality and safety of a wide array of products. From dairy to beverages and beyond, these machines employ precise thermal processes to eliminate harmful pathogens while preserving the nutritional value and flavor of the products.

Types of Pasteurization Machines

Milk Pasteurizer Machines

Milk pasteurization is a thermal process designed to kill harmful bacteria such as E. coli, Listeria, and Salmonella, ensuring the milk is safe for consumption without affecting its taste or nutritional content. There are several types of milk pasteurizers:

Batch Pasteurizers: These heat milk in tanks at 63°C for 30 minutes, making them ideal for small-scale dairy operations.

High-Temperature Short Time (HTST): This method heats milk to 72°C for 15 seconds, then rapidly cools it, and is commonly used in larger facilities.

Ultra-High Temperature (UHT): UHT pasteurization heats milk to 135–150°C for 2–5 seconds, allowing for unrefrigerated storage for up to six months. This method is particularly useful for products like milk, cream, and other dairy products, as well as juices and beverages.

UHT Pasteurizer

UHT pasteurization, also known as ultra-pasteurization, is a process where milk or other dairy products are heated to 280°F (138°C) for just two seconds, then quickly cooled. This method extends the shelf life of products significantly, often up to 60-90 days without refrigeration. UHT pasteurizers are equipped with aseptic filling machines to package the product in sterile conditions, ensuring long-term stability.

Applications in Food Production

Pasteurization machines are utilized across various sectors of the food industry:

Dairy Products: Milk, yogurt, cheese, and ice cream are commonly pasteurized to eliminate pathogens and extend shelf life.

Beverages: Fruit juices, wines, and beers benefit from pasteurization to inhibit enzyme activity and prolong their shelf life.

Other Foods: Pasteurization is also applied to seafood, pickles, jams, and snack foods to ensure safety and maintain quality.

Industrial Considerations

When selecting a pasteurization machine, several factors must be considered:

Capacity: Machines are available in various capacities, from small-scale operations to large industrial plants.

Energy Efficiency: UHT and HTST pasteurizers often utilize thermal vapor recompression (TVR) or mechanical vapor recompression (MVR) to enhance energy efficiency.

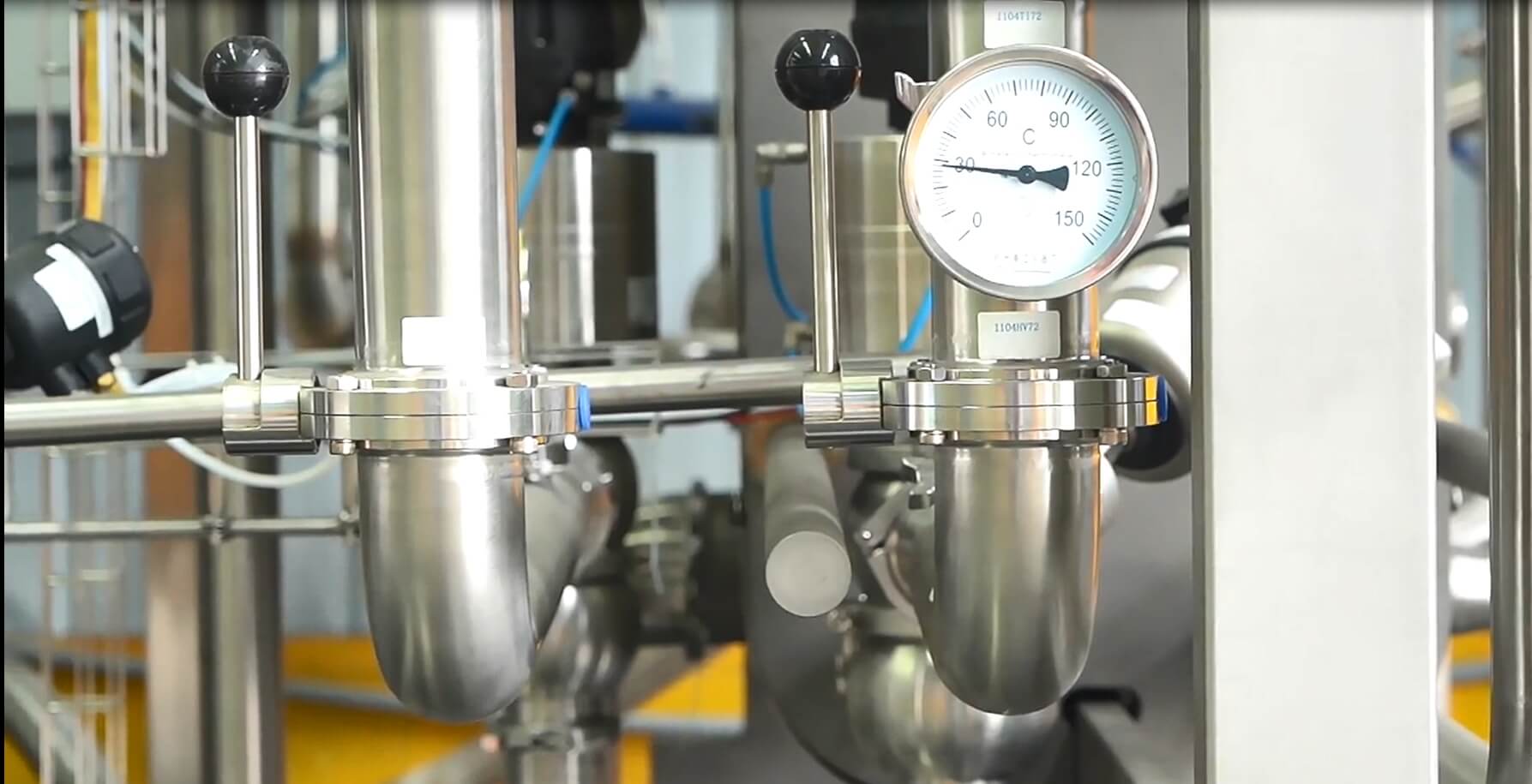

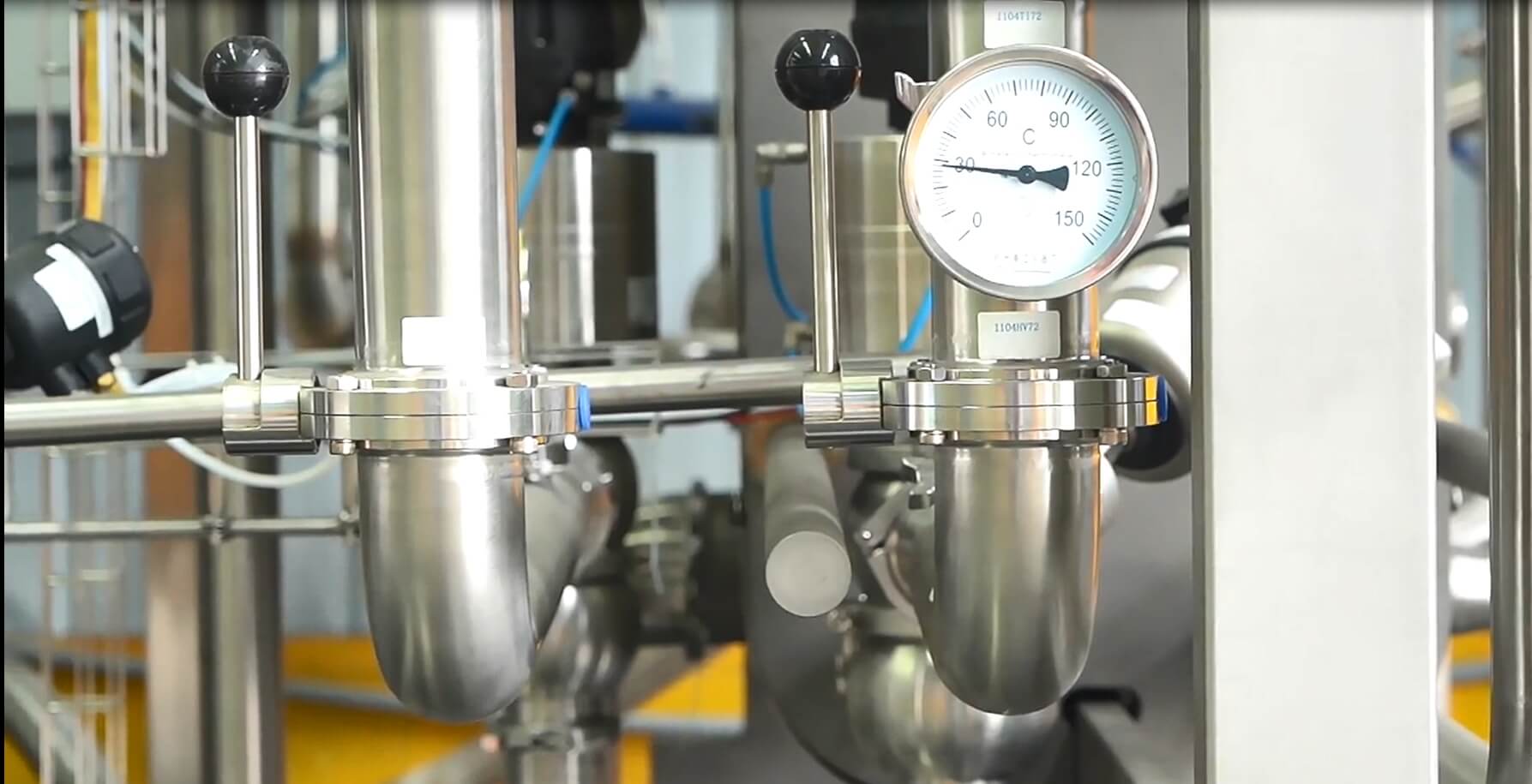

Material: All equipment in contact with food products is typically made from high-grade stainless steel (304 or 316) to ensure durability and compliance with food safety standards.

Automation: Modern pasteurization lines are fully automated, reducing labor costs and increasing efficiency.

Conclusion

Pasteurization machines, including milk pasteurizers and UHT pasteurizers, play a crucial role in the food industry by ensuring the safety and quality of products. Whether for small-scale operations or large industrial plants, these machines offer tailored solutions to meet diverse production needs. As technology advances, pasteurization processes continue to evolve, balancing efficiency with the preservation of product integrity.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of Milk pasteurizers.Please contact us now, and our professional technical engineers will customize the equipment plan for Milk pasteurizers and provide a quotation.Please contact us now to obtain the latest equipment plan and quotation.