Rice protein powder production line: Southeast Asian sports nutrition "new infrastructure"

Sep 11, 2025

——From rice paddies to dumbbells, a complete disassembly of intelligent production line equipment

1、Market situation: Rice turning into protein, just the right trend

-Southeast Asia has a population of 680 million, with an annual increase of 18% in fitness membership. The dependence on whey imports is over 90%, and there is an urgent need for a "local plant-based protein" solution.

-The annual production of rice in Thailand and Vietnam is 170 million tons, and the premium for broken rice is low. On site conversion of high-value protein powder can increase profits by 30-40%.

-In 2024, the popular e-commerce keyword "rice protein powder" in Thailand and Malaysia increased by 42% month on month, with a unit price of US $18-25, which is 5 times higher than that of feed grade.

Edible grade rice protein powder (protein ≥ 80%, digestibility>90%, branched chain amino acids 18%), aimed at sports nutrition, meal replacement, and plant-based milk racing; The by-product rice starch syrup can be sold to beverage factories to achieve "zero waste".

3、 Core production equipment and processes

a. Raw material warehouse&pre-treatment

-500 ton vertical silo+low-temperature circulating dryer (60 ℃ variable frequency), moisture content ≤ 12%.

-Stone removal machine+magnetic separation+color selection, impurities<0.1%.

b. Wet Grinding&Enzymatic Hydrolysis

-Dual axis soaking tank (50 ℃ hot water, 2h) → colloid mill (120 mesh).

-Continuous jet liquefier (high-temperature resistant alpha amylase, 105 ℃/5min), DE value 12-15.

c. Three phase horizontal screw separation

-Centrifugal equipment, with three outputs of heavy phase fiber, light phase protein solution, and medium phase crude starch; The protein recovery rate is ≥ 92%.

d. Membrane concentration and purification

-Ultrafiltration UF (5kDa) washed and filtered 5 times to remove ash and heavy metals;

-Nanofiltration NF recovers oligosaccharides as a natural sweetener for plant milk.

e. Sterilization&Flash Dehydration

-VTIS steam injection instantaneous sterilization at 142 ℃/4s, browning index Δ L ≤ 2;

-Vacuum falling film evaporator concentrates 12% solids to 42%, saving 35% energy.

f. Spray drying

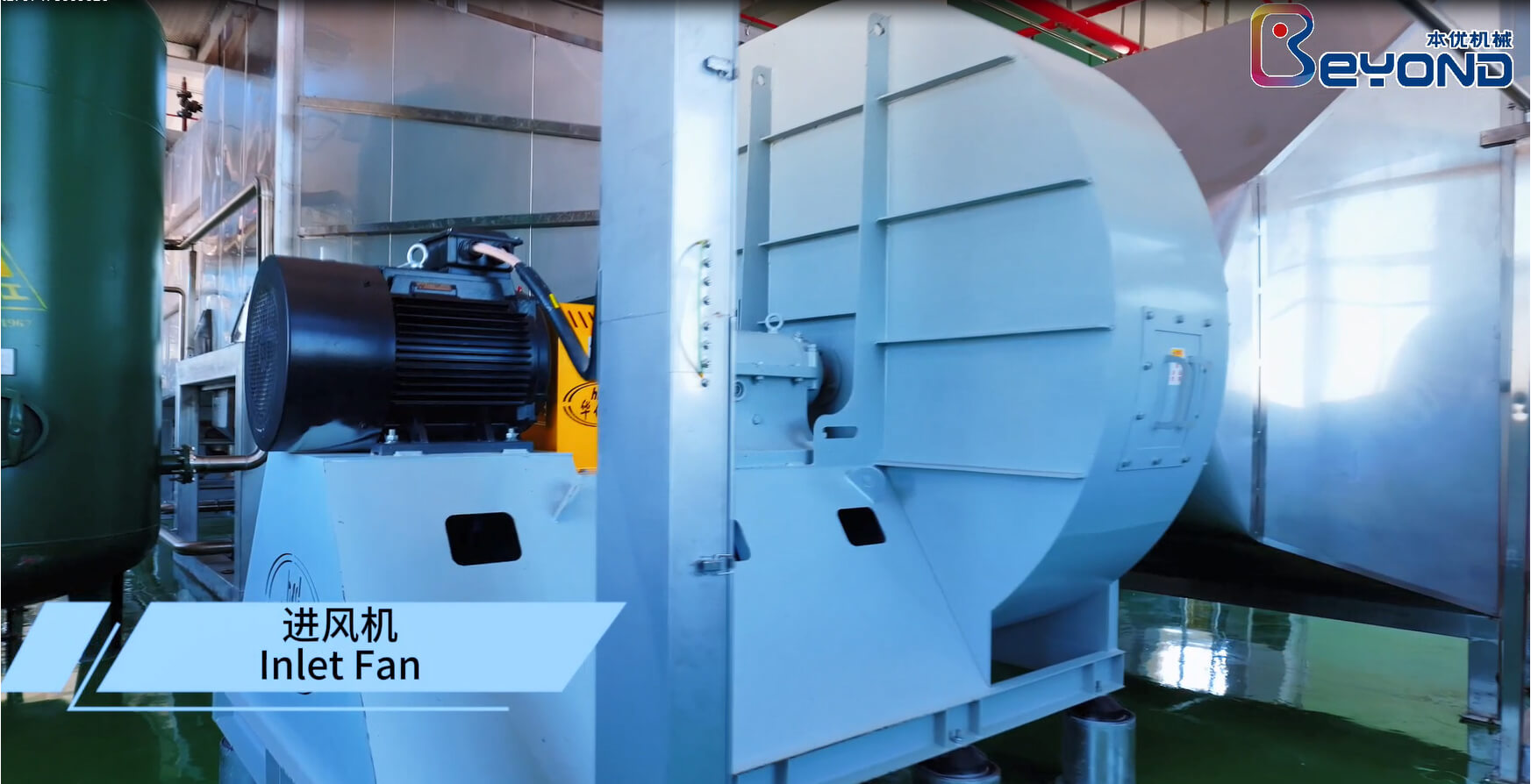

-Centrifugal drying tower (with a diameter of 5m), with an inlet air temperature of 180 ℃ and an outlet air temperature of 75 ℃, equipped with a cyclone and a bag for secondary powder collection, resulting in a powder yield of 98.5%; Built in cold air jacket to maintain protein<50 ℃ and lysine loss<3%.

g. Post processing&Packaging

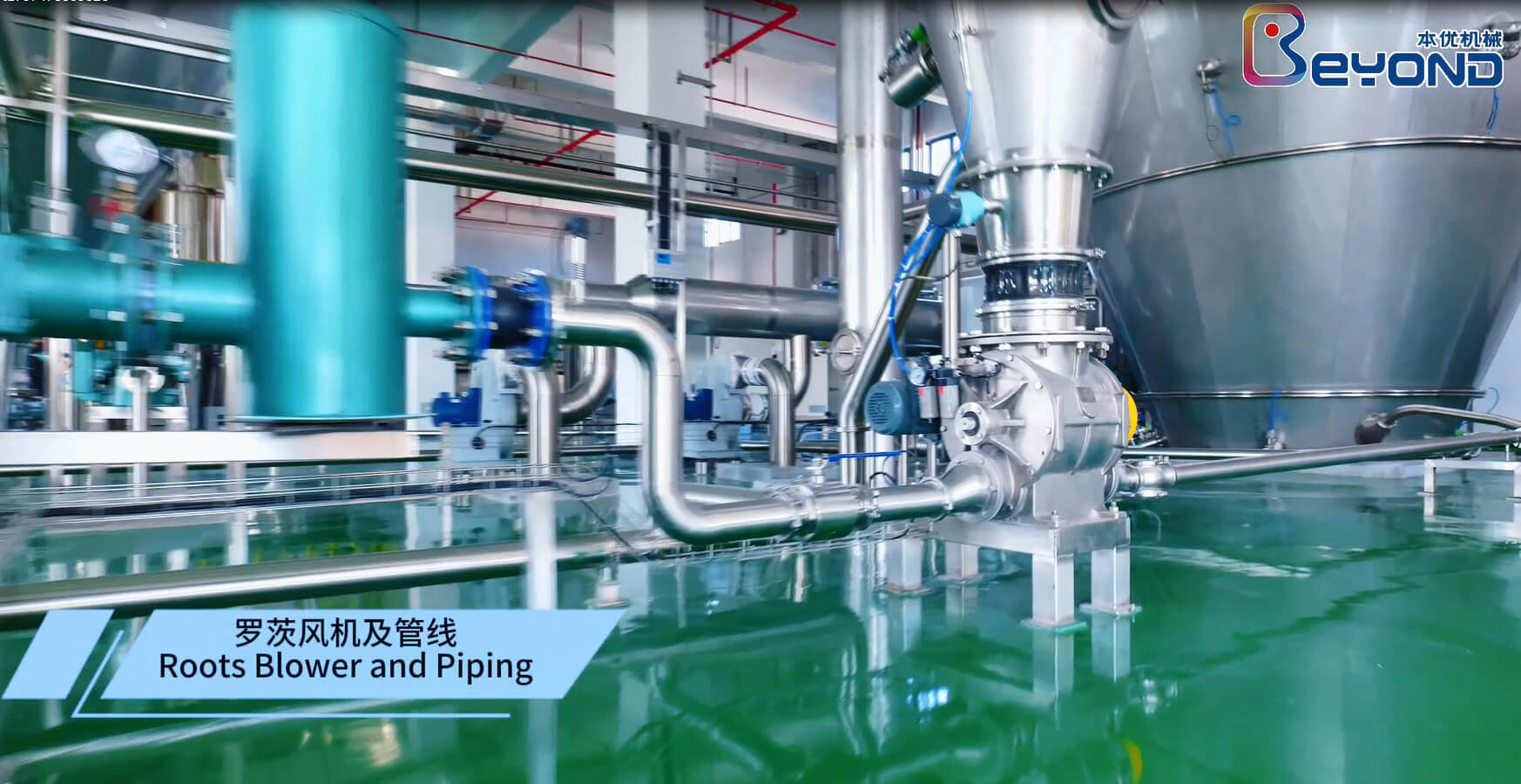

-Vibration fluidized bed secondary cooling → pneumatic conveying to 100000 level clean area;

-Automatic ton bag+400g canning machine, nitrogen filling<1% O ₂, shelf life of 36 months;

-Metal detector+X-ray machine, with Fe ≥ 0.3mm completely removed.

-Module combination : 200kg/h (annual production of 1500t), 500kg/h, 1000kg/h three levels;

-Floor area: 36 × 12m (single story), height 9m, suitable for standard factories in Thailand and Vietnam;

-Energy consumption: steam 1.8t/t powder, electricity 620kWh/t powder, water circulation rate of 85%, in line with Thailand's 4.0 green factory indicators.

5、 Intelligent management

-Edge PLC+cloud SCADA: real-time display of protein, moisture, and chromaticity; AI predicts cleaning nodes, reducing CIP water consumption by 25%.

-Blockchain traceability: Scan the code to see rice planting plots, pesticide residue reports, and carbon footprints, meeting certification requirements.

6、 Suggestions for project positioning

1. Site selection on the border of Vietnam, Thailand, and Myanmar, with a radius of 100km covering both the broken rice production area and the port of Bangkok;

2. The first phase is 500kg/h, with an investment of approximately 4.5 million US dollars, to be recovered within 30 months;

3. Bind with local coffee chains and gym pre-sales, with a premium of over 20% for exports to Singapore.

The Vietnam project will introduce a 500kg/h rice protein production line in 2023, with production reaching Q1 2024. The powder will be exported to the United States at a FOB price of US $4200/t, and the by-product syrup will be sold domestically to produce milk tea. The comprehensive gross profit margin is 38%, and the second phase of 1000kg/h is planned.

From rice husks to powder cans, an intelligent production line instantly turns "field waste" into "muscle fuel". In the outbreak period of sports nutrition in Southeast Asia, the first step is to lay out rice protein powder, which is to seize the pricing power of the next wave of plant raw materials.

News

Hot Product