Oats are herbaceous plants in the Gramineae family, also known as wild oats and naked oats. They are common food crops and are mainly grown in temperate regions of the Northern Hemisphere. Oat is a crop rich in various bioactive substances and has superior nutritional value to many other grains (such as barley, corn, millet, sorghum, etc.). It contains proteins, fats, enzyme compounds, minerals, and β- Various nutrients such as glucan, with delicate starch particles, are easy to digest and absorb, and have various physiological functions such as lowering blood lipids, regulating blood sugar, regulating blood pressure, and reducing gastrointestinal inflammation.

The experiment used oatmeal as the main raw material, and observed its soaking time, slurry liquid ratio, stabilizer, taste, and sterilization conditions to study the processing technology of oatmeal plant protein beverage. A high fiber plant protein beverage was developed, which can enhance the market competitiveness of plant protein beverage and meet the daily needs of consumers.

1.1 Materials and reagents

Oatmeal; Sucrose; Food grade sodium carboxymethyl cellulose; Food grade xanthan gum; Food grade monoglycerides; Food grade sucrose esters.

1.2 Main instruments and equipment

Handheld refractometer; Homogenizer; Thermostatic centrifuge; Sterilization pot; Electric constant temperature drying oven; Digital display constant temperature water bath pot; Electronic balance.

1.3 Test methods

1.3.1 Process flow of oat plant beverage

Raw material selection → soaking → filtering → beating and grinding → filtering → mixing → homogenization → filling → sealing → sterilization → packaging → finished product

1.3.2 Research on the Processing Technology of Oat Plant Beverage

1.3.2.1 Single factor experiment on the main formula of oat plant beverage

1.3.2.1 1 Soaking time

Using 5.00 g oatmeal as a benchmark, the effects of different soaking times (10, 20, 30, 40, 50, and 60 minutes) on the water absorption and expansion of oatmeal were investigated by fixing the volume of water, settling time, and filtration time.

1.3.2.1 2 material liquid ratio

Using 5.00 g oatmeal as a benchmark, the effects of different material liquid ratios (1:5,1:10,1:20,1:30 and 1:40) on raw material utilization and soluble solid content in oat pulp were investigated by fixing soaking time and oven parameters.

1.3.2.2 Single factor test of oat plant beverage composite stabilizer

1.3.2.2 1 Sodium carboxymethyl cellulose addition

Based on 200 mL oat pulp, the addition amounts of xanthan gum, monoglyceride, and sucrose ester were fixed at 0.01%, 0.03%, and 0.05%, respectively. The effects of different sodium carboxymethyl cellulose additions (0.10%, 0.15%, 0.20%, 0.25%, and 0.30%) on the static stratification rate of oat pulp were investigated.

1.3.2.2 2. Addition amount of xanthan gum

Based on 200 mL oat pulp, the addition amounts of sodium carboxymethyl cellulose, monoglyceride, and sucrose ester were fixed at 0.2%, 0.03%, and 0.05%, respectively. The effects of different xanthan gum additions (0.005%, 0.010%, 0.025%, 0.040%, and 0.055%) on the static stratification rate of oat pulp were investigated.

1.3.2.2 2 Monoglyceride addition amount

Based on 200 mL of oat pulp, the addition amounts of sodium carboxymethyl cellulose, xanthan gum, and sucrose ester were fixed at 0.20%, 0.01%, and 0.05%, respectively. The effects of different monoglyceride additions (0.01%, 0.03%, 0.05%, 0.07%, and 0.09%) on the static stratification rate of oat pulp were investigated.

1.3.2.2 3 Sucrose ester addition amount

Based on 200 mL oat pulp, the addition amounts of carboxymethyl cellulose sodium, xanthan gum, and monoglyceride were fixed at 0.2%, 0.01%, and 0.03%, respectively. The effects of different sucrose ester additions (0.01%, 0.03%, 0.05%, 0.07%, and 0.09%) on the static stratification rate of oat pulp were investigated.

1.3.2.3 Orthogonal test of oat plant beverage composite stabilizer

On the basis of single factor analysis, the optimal levels of four factors, namely sodium carboxymethyl cellulose addition, xanthan gum addition, monoglyceride addition, and sucrose ester addition, were selected. Based on the beverage quality evaluation results, a four factor and three level orthogonal experiment was conducted to determine the optimal stabilizer for oat plant beverage.

1.3.2.4 Determination of sucrose content in oat plant beverages

According to the best results obtained in sections 1.3.2.1, 1.3.2.2, and 1.3.2.3, the processing will be carried out according to the process steps. 3%, 4%, 5%, 6%, and 7% sucrose will be added to a 50 mL sample, and sensory evaluation will be conducted to determine the optimal amount of sucrose added.

1.3.2.5 Determination of sterilization conditions

The prepared oat plant beverage samples were sterilized at 110 ℃/25 min, 110 ℃/30 min, 115 ℃/20 min, 115 ℃/25 min, 121 ℃/15 min, and 121 ℃/20 min, respectively, and their stability was observed at room temperature for 60 days.

2 Results and Analysis

2.1 Single factor test results of the main formula of oat plant beverage

2.1.1 The effect of soaking time on the water absorption and expansion rate of oatmeal

As the soaking time increases, the water absorption and swelling of oatmeal first show an increasing trend; When the soaking time is 30 minutes, the water absorption and expansion rate of oatmeal reaches its maximum; After soaking for more than 30 minutes, the water absorption and swelling rate of oatmeal decreased; Therefore, it is advisable to choose a soaking time of 30 minutes for oatmeal.

2.1.2 Effect of Material Liquid Ratio on the Utilization Efficiency of Oatmeal Raw Materials and the Content of Soluble Solids in Oat Pulp

The soluble solid content gradually decreases and tends to stabilize as the proportion of water in the material to water ratio increases. The utilization rate of raw materials first increases with the proportion of water in the material to water ratio. When the material to water ratio reaches 1:20 g/mL, the utilization rate of raw materials reaches its highest, and decreases as the material to water ratio continues to increase. By combining two curves, the optimal quality of oat pulp is achieved when the material water ratio is 1:20 g/mL.

2.2 Single factor test results of oat plant beverage composite stabilizer

When the addition of sodium carboxymethyl cellulose is 0.3%, the beverage is almost non layered after 24 hours of standing. It can be seen that the addition of 0.3% sodium carboxymethyl cellulose can improve the stability of oat plant beverages. When the amount of xanthan gum added is 0.055%, after 24 hours of standing, the beverage is almost non layered. It can be seen that the addition of 0.055% xanthan gum can make the oat plant beverage have good stability. By increasing the amount of monoglyceride added, the static stratification rate of oat plant-based beverages first showed a decreasing trend. When the monoglyceride added amount was 0.07%, the static stratification rate of oat plant-based beverages was the lowest. When the monoglyceride added amount was greater than 0.07%, the static stratification rate of oat plant-based beverages increased. Therefore, it is advisable to choose a monoglyceride added amount of 0.07%. By increasing the amount of sucrose ester added, the static stratification rate of oat plant beverage shows a decreasing trend. When the amount of sucrose ester added is 0.07%, the static stratification rate of oat plant beverage is the lowest. When the amount of sucrose ester added is greater than 0.05%, the static stratification rate of oat plant beverage increases. Therefore, it is advisable to choose a single glyceride addition of 0.07%.

2.3 Orthogonal test results of oat plant beverage composite stabilizer

The results of orthogonal experimental design with static stratification rate as the indicator are shown in Table 2, and the results and analysis of orthogonal experimental design with centrifugal sedimentation rate as the indicator are shown in Table 3.

From the intuitive analysis results in Tables 3 and 4, it can be seen that when the static stratification rate is used as the evaluation index, the influence of the four factors on the static stratification rate is in the order of B>A>C>D, that is, the amount of xanthan gum added>the amount of sodium carboxymethyl cellulose added>the amount of monoglyceride added>the amount of sucrose ester added. A3B3C2D3 is the optimal combination scheme. When using the centrifugal precipitation rate as an indicator, the influence of four factors on the centrifugal precipitation rate is B>A>C>D, namely the amount of xanthan gum added>the amount of sodium carboxymethyl cellulose added>the amount of monoglyceride added>the amount of sucrose ester added. Although the evaluation indicators are different, the four factors have the same primary and secondary effects, namely xanthan gum and carboxymethyl cellulose sodium are the main influencing factors, while monoglycerides and sucrose esters are secondary influencing factors. After comprehensive consideration, the static stratification rate is mainly used as the reference standard, and A3B3C2D3 is selected as the optimal composite stabilizer combination, which includes 0.3% sodium carboxymethyl cellulose addition, 0.04% xanthan gum addition, 0.07% monoglyceride addition, and 0.07% sucrose ester addition.

2.4 Effect of sucrose on the sensory quality of oat plant beverage

Add 2%, 3%, 4%, 5%, 6%, and 7% sucrose respectively for sensory evaluation. The effect of sucrose addition on the taste of oat plant-based beverages is shown in Table 4.

When the amount of sucrose added is 4.0%, the sweetness of oat plant beverage is better.

2.5 Effects of Different Sterilization Conditions on the Stability of Beverages

High temperature sterilization has a certain impact on the stability of beverages. Different sterilization temperatures and times were used for the experiment, and the stability was observed after 60 days at room temperature. The effect of sterilization conditions on the stability of beverages is shown in Table 5.

Sterilization at 121 ℃ for 15 and 20 minutes has the same stability effect and meets hygiene requirements through microbial testing. Therefore, 121 ℃ and 15 minutes are the optimal sterilization conditions.

Using oatmeal and white sugar as the main raw materials, a high protein plant beverage was developed through a series of processes such as grinding, homogenization, and formulation. Through single factor and orthogonal experiments, the optimal process for oatmeal plant protein beverage was obtained: soaking time of oatmeal for 30 minutes, slurry water ratio of 1:20g/mL, addition of sodium carboxymethyl cellulose 0.3%, addition of xanthan gum 0.04%, addition of monoglyceride 0.07%, and addition of sucrose ester 0.07% The addition of 4% sucrose showed good stability after sterilization at 121 ℃ for 15 minutes. The experimental results have certain guiding significance for the preparation and production practice of oat plant protein beverages.

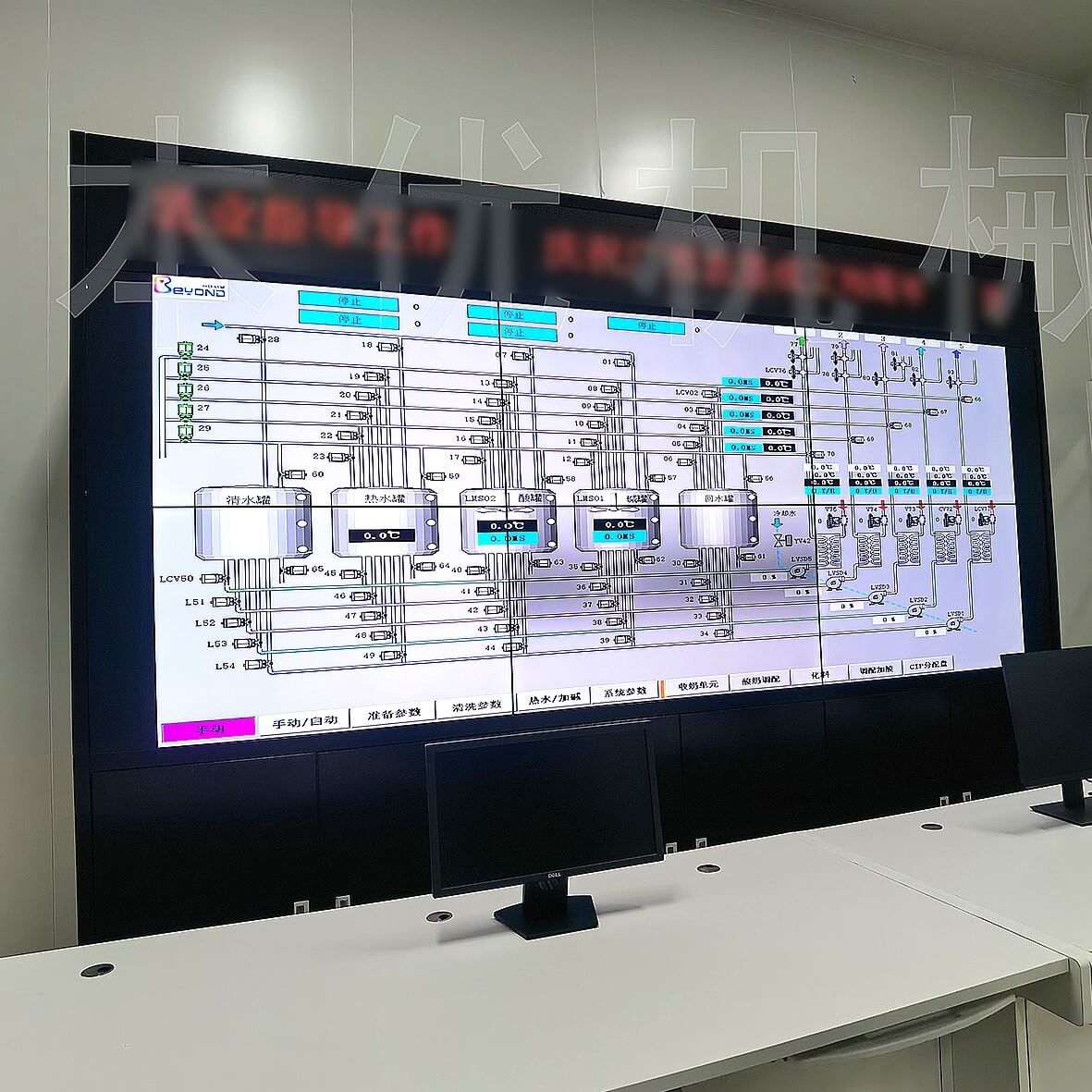

Beyond Machinery specializes in the design and manufacturing of oat milk processing lines. Our customers are from all over the world, and they have achieved remarkable success in their respective fields. We have over 20 years of experience in the field of food processing machinery. We are willing to establish long-term win-win relationships with customers. We share our technology and experience with customers to help them quickly convert investment returns. Contact us now and you will receive the latest product customization solutions and quotations.