Description:

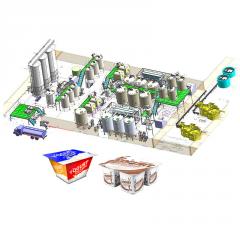

A plant-based milk processing line is a production system designed to process plant-based ingredients such as nuts, grains, and seeds into milk alternatives. Here is a general overview of the different steps involved in a typical plant-based milk processing line:

Raw Material Reception: The plant-based ingredients are received and inspected for quality. They are then stored in designated areas until they are ready to be processed.

Cleaning and Sorting: The raw materials may need to be cleaned and sorted to remove any impurities or foreign materials. This step ensures the safety and quality of the final product.

Soaking or Pre-Treatment: Some plant-based ingredients, like nuts or grains, may need to be soaked or pre-treated before further processing. This step helps to soften the ingredients and make them easier to blend.

Grinding or Milling: The soaked or pre-treated ingredients are then finely ground or milled to create a smooth paste or slurry. This step helps to break down the ingredients and release their natural oils and flavors.

Mixing and Blending: The ground ingredients are mixed with water to create a homogenous mixture. This step determines the desired concentration and consistency of the plant-based milk.

Heating and Cooking: The mixture is heated to a specific temperature to ensure food safety and to enhance flavor development. This step may also involve pasteurization to extend the shelf life of the final product.

Filtration and Separation: The heated mixture is passed through a filtration system to remove any solid particles or unwanted impurities. This step helps to achieve a smooth and clean milk-like consistency.

Homogenization: The filtered mixture may undergo homogenization to achieve a uniform texture and prevent separation of solids and liquids. This step improves the stability and quality of the final product.

Cooling and Packaging: The plant-based milk is cooled down to an appropriate temperature and then packaged into containers such as cartons, bottles, or pouches. This step ensures the freshness and shelf life of the product.

Quality Control: Throughout the entire processing line, quality control measures are implemented to ensure that the plant-based milk meets the required standards for taste, texture, nutritional content, and safety.

Storage and Distribution: The packaged plant-based milk is stored in a designated area until it is ready for distribution. It is then transported to retailers, supermarkets, or other distribution channels for sale to consumers.

Shanghai beyond machinery co., ltd is specialized in supplying various kinds of plant based milk processing line.

Shanghai Beyond can supply complete turnkey projects for customers, integrating with designing, equipment manufacturing, to installation and commissioning and also training the operators.

Large type central control system: Full-auto material system、Full-auto blending system、Full-auto CIP system、Automatic online mixing system、Full-auto material dissolving system、Full-auto valve system、Full-auto valve system.

Milk process: milk transporting tank or vessels, milk filter and collection tank; cooling and storaging tank(milk chilly tank), Mixing/Blending and milk standardization, cream separation, UHT sterilizer(tubular type or plate type) homogenization, degassing, and filling.

Process Introduction

Design different process routes for different raw materials through processes such as raw material pretreatment, pulping, enzymatic hydrolysis, separation, standardization, (concentration, powder spraying), etc;

Oat milk mixer

Suitable for: Enzymatic hydrolysis stirring of viscous materials such as oat pulp, with features such as scraping walls, flipping mixing, and adjustable speed, solving the problems of poor mixing effect and uneven heating of viscous materials in traditional mixing tanks.

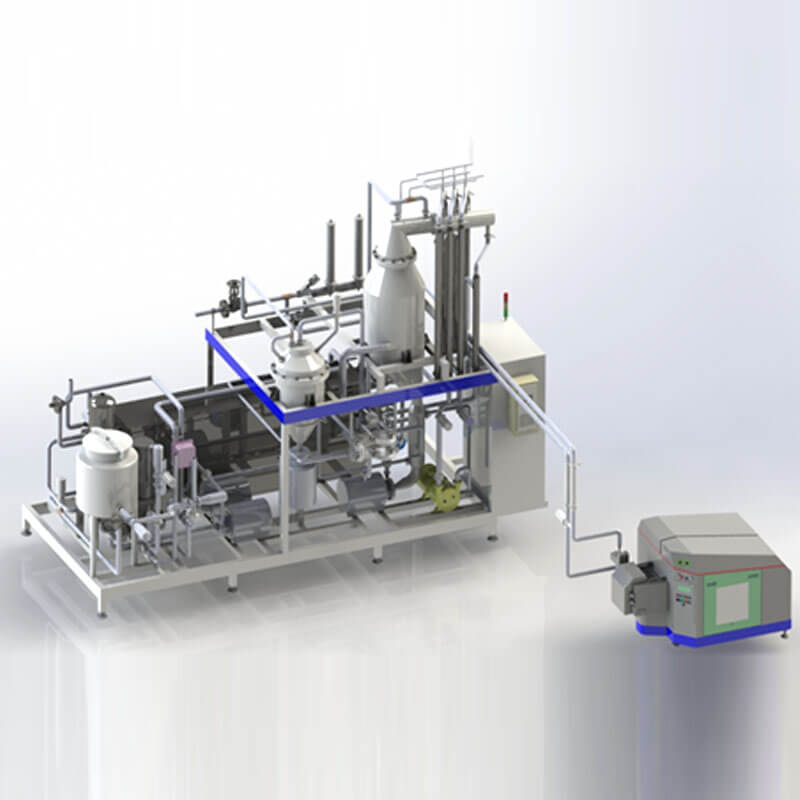

Steam jet sterilizer

Suitable for dairy products, beverages, thick coconut milk, as well as products with high viscosity such as milk caps, cream, and ice cream puree. Its unique direct heating method greatly reduces the chemical changes that occur due to prolonged heating compared to traditional indirect heating, ensuring the high quality of the product. Due to its maximum retention of the flavor and nutritional components of the product, it is a high-end dairy and cream product The preferred choice for production lines such as ice cream syrup.

Equipment features:

1. Instantaneous heating, the time required for material heating is less than 0.2s

2. Instantaneous heating up to 135-143 ℃

3. Heating only causes minimal chemical changes to the material, retaining the original flavor

4. High temperature flash evaporation effectively removes product odors

5. Suitable for sterile or non sterile products

Direct heating UHT treatment

Direct heating and cooling to reduce product chemical changes

Two heating methods: Steam injection steam injection and Steam injection steam immersion.

The production capacity ranges from 2000 to 30000 l/h

Steam injection+steam immersion

Spray sterilization and immersion sterilization can be integrated into one system, making production choices more flexible. The production process can be easily switched through adapter plates to adapt to different heat treatment needs.

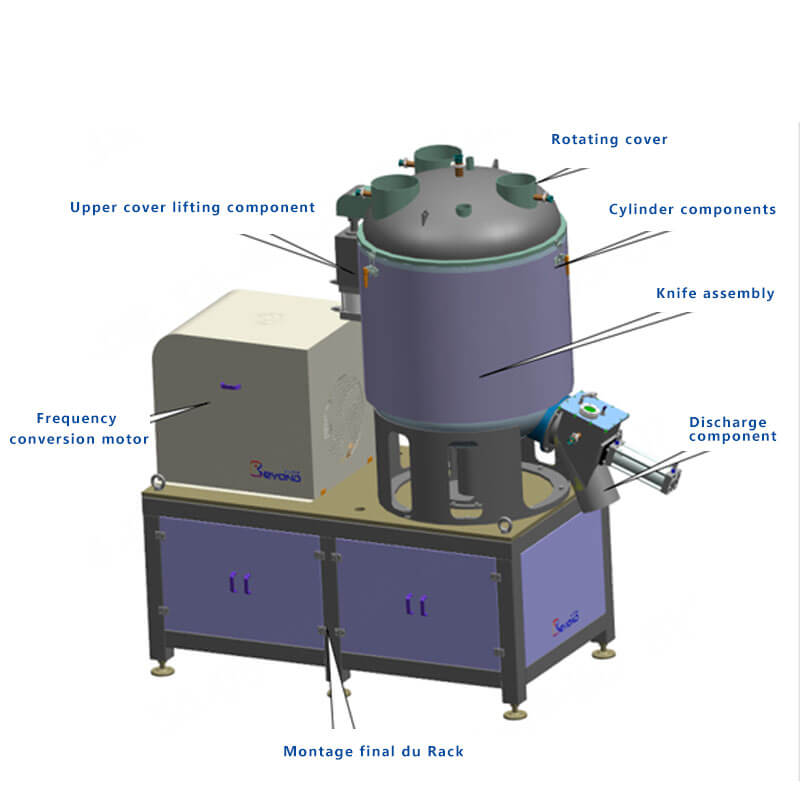

High speed mixer

The main features are as follows:

1. Due to the action of centrifugal force, the high-speed rotating blade slurry at the bottom continuously feeds the bottom material upwards along the cylinder wall, while the upper material falls back from the center, causing the material to circulate and form a vortex.

2. Dry and wet mixing for 2-5 minutes per batch, with uniformity>99.8%

3. The side mounted high-speed dispersal knife forcibly opens and disperses the material sent by the rotating blade slurry.

4. Due to the high-speed rotation of the rotating blade and high-speed dispersing knife mentioned above, the material can be mixed evenly in a short period of time (1-5 minutes), and its mixing speed and uniformity are beyond the reach of existing domestic mixers. There are no particles in the mixed material (wet material), and the mixing uniformity is>99.8%.

5. Adopting pneumatic discharge valve, reliable sealing, fast discharge speed, and easy equipment cleaning.

6. The machine is made of stainless steel both inside and outside, operated in a closed manner, and will not produce material volatilization, deterioration, or loss during the mixing (kneading) process.

7. This machine is suitable for mixing dry and wet materials of different proportions evenly.

8. It is very effective for uniform mixing (kneading) of materials with large proportion differences and specific gravity differences. 9. Equipped with a feeding and dust removal system, the feeding and discharging are dust free and sealed.

10. Equipped with a CIP cleaning device, there is no need for manual cleaning.

Designing a plant-based milk production line requires comprehensive consideration of production processes, equipment selection, raw material and product characteristics, and the layout of the production line. Here is a detailed solution:

1. Preparation of raw materials for production process

• Raw material reception and storage: Receive plant materials (such as soybeans, almonds, oats, etc.) and store them in a suitable environment to avoid spoilage.

• Pre treatment: Pre treatment steps such as cleaning, soaking, and grinding are carried out on plant raw materials to improve extraction efficiency and product quality.

extract

Grinding: Use a grinding machine to grind the pre treated plant raw materials into a slurry.

• Separation: Use a centrifuge or filter to separate the solid residue from the slurry, resulting in a clear plant-based milk solution.

Allocation

• Preparation: Mix the extracted plant-based milk in a certain proportion, and add appropriate amounts of water, sugar, stabilizers, vitamins, and other ingredients according to the formula to adjust the taste and nutritional content.

Homogenization

Homogenization: Use a homogenizer to refine the particles in the mixture, making it more uniform and improving taste and stability.

sterilization

Sterilization: Through high-temperature instantaneous sterilization (UHT) or pasteurization treatment, harmful microorganisms are killed to ensure the safety of the product.

cooling

• Cooling: Quickly cool the sterilized mixture to a suitable temperature to prevent bacterial growth.

filling

• Filling: Fill the cooled mixture into bottles, cans, or bags to ensure good sealing and prevent contamination.

seal

Sealing: Use a sealing machine to seal the packaging container to ensure sealing performance.

Labeling

Labeling: Attach labels to packaging containers, indicating product information, production date, shelf life, etc.

packing

• Packaging: Packaging the finished product for easy transportation and sales.

test

• Inspection: Conduct quality inspection on finished products to ensure compliance with relevant standards and regulatory requirements.

Storage

• Storage: Store qualified products in a suitable environment, usually a cool and dry place, to ensure product quality and shelf life.

2. Equipment selection: Main equipment

Raw material receiving and storage equipment: storage tanks, cold storage.

• Pre processing equipment: cleaning machine, soaking tank, grinding machine.

Extraction equipment: centrifuge, filter.

• Mixing equipment: mixing tank, mixer.

Homogenization equipment: Homogenizer.

Sterilization equipment: UHT sterilizer, pasteurizer.

Cooling equipment: cooling tower, cooling tunnel.

Filling equipment: filling machine.

Sealing equipment: sealing machine.

Labeling equipment: Labeling machine.

• Packaging equipment: packaging machine.

Inspection equipment: quality testing instruments.

Storage equipment: warehouse, cold storage.

3. Raw materials and product raw materials

• Plant materials: Fresh, high-quality plant materials such as soybeans, almonds, oats, coconuts, etc.

Accessories: water, sugar, stabilizers, vitamins, etc., used to adjust taste and nutritional content.

product

• Ordinary plant-based milk: Basic plant-based milk products.

Functional plant-based milk: added with specific functional ingredients such as calcium, vitamin D, etc.

• Low sugar or sugar free plant based milk: suitable for diabetes patients or consumers with strong health awareness.

Special flavored plant-based milk: added with special flavors such as vanilla and chocolate to meet different market demands.

4. Customized demand production capacity

Capacity selection: Select equipment with appropriate capacity based on the size and demand of the factory.

Flexibility: Design adjustable production lines to meet the production needs of different products.

Product diversity

Multi flavor production: Design production lines for multiple flavors to meet the needs of different markets.

Special requirements: Provide plant-based milk production lines with special needs such as organic and low sugar.

Degree of automation

• Automation level: Select different levels of automation equipment based on budget and management needs.

Information management: Introduce information management systems to improve production efficiency and management level.

Environmental requirements

Wastewater treatment: Design a wastewater treatment system that complies with local environmental regulations.

• Waste management: Reasonably handle the waste generated during the production process.

hygienic standard

GMP and HACCP: Ensure that all equipment and facilities comply with hygiene standards such as GMP and HACCP.

• Cleaning and maintenance: Regularly clean and maintain the equipment to ensure the hygiene of the production environment.

5. Design and plan the overall layout

Raw material receiving area: used for receiving and inspecting the quality of raw materials.

Storage area: used for storing raw materials and finished products.

Processing area: including pre-treatment, extraction, blending, homogenization, sterilization, cooling and other processes.

Filling area: used for filling and sealing finished products.

Labeling area: used for labeling finished products.

• Packaging area: used for the outer packaging of finished products.

Finished product storage area: used for storing finished products and preparing them for shipment.

• Laboratory: used for quality control and testing.

Office and Rest Area: Provides a place for employees to work and rest.

6. Technical support

Automation and informatization: Introduce automated production lines and information management systems to improve production efficiency and management level.

• Training: Regularly train employees to ensure they master the latest technology and operating procedures.

After sales service: Provide comprehensive after-sales service and technical support to ensure the normal operation of the production line.