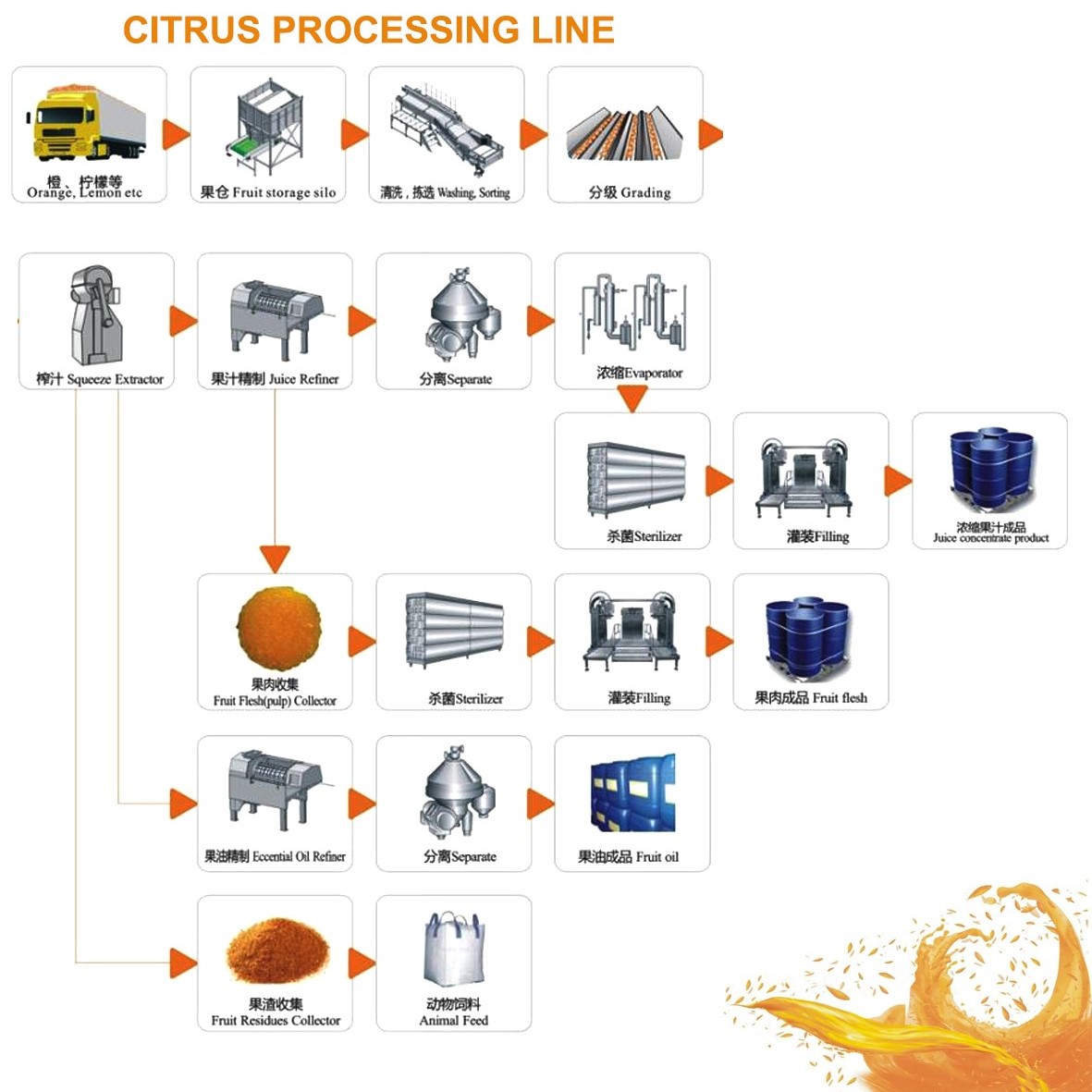

A citrus/lemon/orange processing line is a system specifically designed to efficiently process and transform citrus fruits, such as lemons and oranges, into various products such as juice, pulp, concentrate, and essential oils.

The processing line typically consists of several stages, including sorting and grading, washing, drying, juicing, pasteurization, and packaging. Each stage plays a critical role in ensuring the quality, safety, and shelf life of the final citrus products.

Sorting and grading: Citrus fruits are sorted based on their size, color, and quality. This helps ensure that only high-quality fruits are further processed.

Washing: The fruits are thoroughly washed to remove any dirt, debris, or unwanted substances.

Drying: After washing, the fruits are dried to remove excess moisture, which helps prolong the shelf life of the processed products.

Juicing: The fruits are then squeezed or pressed to extract the juice. This can be done either manually or using automated machines.

Pasteurization: The extracted juice is pasteurized to eliminate any harmful microorganisms, enzymes, or pathogens that may be present. Pasteurization also helps extend the shelf life of the juice.

Packaging: The processed juice is packaged into bottles, cartons, or other containers. This may involve filling, labeling, and sealing the containers to ensure product integrity.

In addition to these primary stages, a citrus processing line may also incorporate additional processes depending on the desired end products. These can include steps such as pulp extraction, concentration, freezing, and the production of essential oils.

Overall, a citrus/lemon/orange processing line is designed to efficiently transform raw citrus fruits into high-quality, safe, and marketable products that meet the demands of consumers.

The capacity of the citrus processing line ranges from 10 tons perday to 500 tons day,the end product that can be produced is NFC juice,FCOJ juice,pulp,peel oil and animal feed.All the citrus processing equipment is CIP capable and made of food-grade sus304 material,this hygienic advantage ensure the production of optimum products.

Configuration characteristics of citrus fruit processing production line:

1. Wide range of raw materials, this production line is suitable for all kinds of citrus fruits with the same characteristics, such as orange, lemon, orange, Huyou, grapefruit, etc;

2. The configuration of production line is flexible, and different functional equipment can be flexibly configured according to different final product requirements of customers, such as debittering, deacidification, essential oil preparation and concentration equipment;

3. According to different investment amount and product positioning of customers, customers can configure ordinary, middle and or high-end products according to their own requirements;

4. The final product has pure flavor, bright color and high yield;

5. The whole line has high degree of automation, low labor intensity, simple operation, reliable performance and low operation cost;

6. The whole production line adopts sanitary design, with thorough cleaning and high hygiene level.

Technical parameters of citrus fruit processing line:

Raw materials: fresh orange, orange, lemon, Huyou, grapefruit

Final products: NFC fresh juice, concentrated juice, essential oil, pulp (orange velvet, etc.), cysts

Capacity: 20 t / D - 2000 t / D

Fruit juice yield: ≥ 90%

Solid content: 7 ~ 12brix

Packaging: sterile bag / glass bottle / PET bottle / roof bag / Tetra Pa

Citrus oil extracting machine

The citrus oil extracting machines is specailly designed for grinding and extracting oil from citrus peel.The machine is made of sus304 material and with a high oil yield rate,the capacity for the citrus oil extractor is from 2-10 tons available.

Citrus juice extracting machine

There are two types of juice extractors for citrus fruits:

The first is a squeezer-type citrus juice extractor(also called whole fruit cup extractor)is specially designed for citrus juice extracting,the citrus extractor has

three to five channels,which can sort the citrus according to different size,then through the channel to feed citrus into the extractor cups,it can separate the juice,

oil,peel and seeds,and the capacity can reach to 500 citruss per-hour.The juice extractor is suitable fro citruses,mandarins,tangerines,key limes,persian limes and

lemons juice extracting.

The second extractor is roller half cutting juice extractor,this extractor is composed of two rollers and one sharp knife between two rollers,when the fresh citrus

feeding into the hopper,the knife will cut the citrus fruits into half and then send them to two rollers,with the rotation of the pressure of the pressure roller,the gap

between the pressure roller and the stainless steel screen becomes smaller and smaller.Under the action of the squeezing force,the citrus juice is obtained.The roller

half extractor is suitable for extracting limes,lemons,and citruss which side is under 50-60mm.Use this extractor can not separate the oil and seeds,but the processing

capacity is bigger than the cup extractors.

Citrus peel oil recovery system

The citrus oil recovery system needs two stage separating,the first separator is mainly for oil concentration,and the second stack centrifuge separator is for oil purification.

The first stage removes most of the water and insoluble solids from the emulsion.This stage may involve more than one desludging centrifuge,depending upon the volume being

processed.The oil-rich emulsion(cream)production by this centrifuge should have an oil ranging between 65% to 85%(and preferably>75% for best results).This oil-rich cream becomes the feedstock for the second stage polishing centrifuge.The second stage polishing centrifuge is where the remaining water and some cloudy particles are removed.The oil discharged from this stage is the fine essential oil that can be ready for storage.

Citrus juice refiner and finisher

We use a scrape refine/finisher to obtain the pure citrus juice.Using the principle of combining crushing and rapid centrifugation,the juice and pomace can be quickly separated,and the pit can be effectively removed.As the machine works in a fully enclosed state,it can effectively reduce the oxidation of the citrus juice.

Citrus juice centrifuge separator

Citrus/citrus juice after scrape finisher separation,the pulp content is about 8%~12% in the juice,if you want to make lower pulp content citrus juice,then the two-phase stack centrifuge separator with 4000-8000rpm rotate speed can be used for the application.After centrifuge separation,the pulp in citrus juice can be reduced 1%~3%.

Citrus juice concentration system

The product obtained from a process in which water is removed from citrus juice by utilizing heat under vacuum conditions.The citrus concentrate is normally concentrated to 65 brix which has the soluble solids content of 7 equal volumes of citrus juice at 11.8 brix.

The citrus juice flows from one stage to the next without recycling.And cool down in a very short time.The evaporator can also be equipped with an aroma

recovery system where the aromas are extracted from the juice.Before leaving the evaporater,the concentrated juice passes through a flash cooler which drops the temerature to 10 ℃

Citrus juice pasteurization system

citrus juice treatment used tubular type pasteurizer.A heat treatment that kills some but not all of the microorganisms present in juice in order to minimize microbial growth in subsequent handling and storage.A temperature of 70 ℃ for one minute is required to sufficiently reduce the microbial load in citrus juice.Pectinesterase inactivation requires a minimal heat treatment 90 ℃ fro 10 seconds.

There are two pasteurization processes in citrus juice processing line.The primary pasteurization should be performed after juice extrating to inactivate PME as soon as possible.It is pasteurized above 95-98℃ for 10-30 sec.The secondary pasteurization(sterilization)carried out prior to juice packaging,involves NFC after bulk storage or juice reconstituted from concentrate.It is for microbial destruction rather than the inactivation of enzymes.Since microorganisms are less heat resistant than enzymes,the second pasteurization maybe carried out at a lower temperature than the first pasteurization.

Citrus juice filler system

According to different end products,different filling machines are adopted.For NFC citrus juice,it is usaually will be filled into PET or glass bottles,the filling temperature is 5-7 ℃ and the shelf life is about 15 day-3 months;For concentrated citrus juice,aseptic bags filler or drum filler is used,after filling, the products should be stored in the refrigerator.

Technical Data For Orange Processing Line:

|

Raw material: |

Fresh Orange, Lemon, Citrus, Pomelo, Grapefruit |

|

End product: |

NFC Fresh Nature Juice, juice Concentrate, oil, orange Pulp, cyst |

|

Production capacity: |

20t/D-2000t/D |

|

Output percentage: |

≥90% |

|

Solid content |

7~12brix |

|

Packing type for end product: |

Aseptic Bag/glass Bottle/pet Bottle /gable Top Box |

Customizing a citrus juice processing line involves a series of steps to ensure that the final setup meets your specific requirements and quality standards. Here’s a detailed guide on how to approach this process:Customizing a Citrus Juice Processing Line

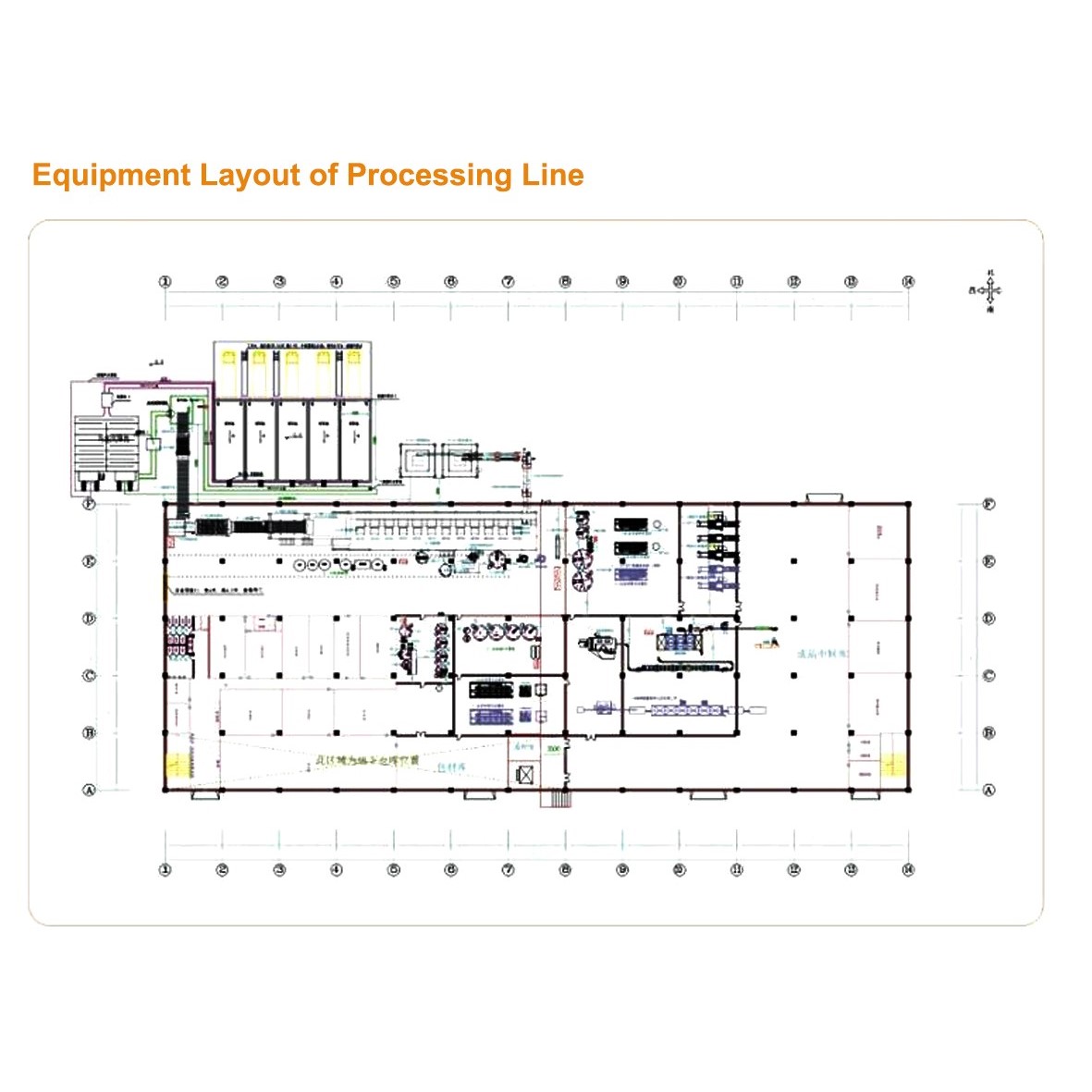

•Site Visit: If possible, visit your facility to assess space, existing equipment, and infrastructure.

•Cost-Effectiveness: Balance initial investment with long-term operational costs to ensure a return on investment.

•Technical Support: Ensure the chosen equipment comes with reliable technical support and maintenance services.

•Training: Train your staff on how to operate and maintain the equipment.

•Continuous Improvement: Implement a continuous improvement program to enhance efficiency and quality over time.

•Supplier Relationships: Maintain good relationships with equipment suppliers for ongoing support and upgrades.