Orange juice is a popular beverage enjoyed worldwide for its refreshing taste and nutritional benefits. The production process involves several key steps, from harvesting oranges to packaging the final product. This article provides a detailed overview of the industrial process, focusing on the machinery and techniques used in modern orange juice production.

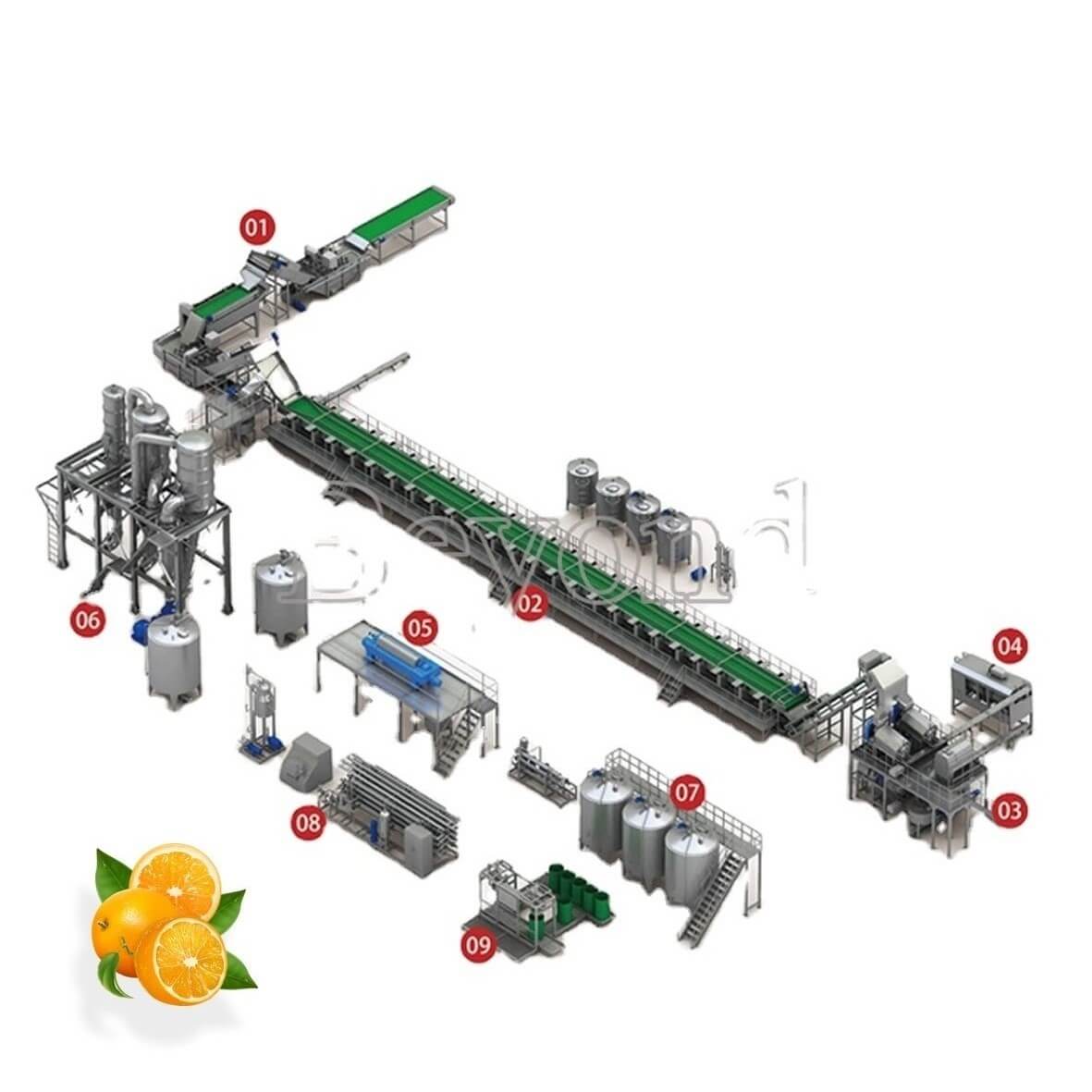

The process begins with the careful selection and harvesting of ripe oranges. These fruits are typically grown in warm climates, such as Florida, California, Brazil, and Spain. Once harvested, the oranges are transported to processing facilities, where they undergo rigorous washing and sorting. This step is crucial for ensuring the safety and quality of the final product. Modern facilities use specialized washing machines that clean the oranges by spraying, rolling, and other methods to remove dirt, pesticide residues, and microorganisms.

After washing, the oranges are sent to juicing machines. These machines use mechanical extraction to press the oranges and extract the juice. Modern juicers are designed to adjust pressure based on the size and hardness of the oranges, ensuring maximum juice yield. The extracted juice is then filtered to remove any remaining pulp, seeds, or solid particles, resulting in a smooth and clear liquid.

To ensure the safety and extend the shelf life of the juice, it undergoes pasteurization. This process involves heating the juice to a specific temperature for a set amount of time, effectively killing any harmful bacteria or microorganisms while retaining its essential nutrients. Pasteurization is a critical step in maintaining the quality and safety of the final product.

After pasteurization, the juice is pumped into a deaerator to remove any remaining air bubbles, which helps prevent oxidation and maintains the juice’s freshness. Depending on the desired flavor profile, the juice may undergo flavor adjustment. This can involve combining juice from different orange varieties or adding natural flavors to enhance taste.

The final step is packaging the juice in aseptic containers, glass bottles, or cartons. Aseptic packaging involves sterilizing the containers and filling them with the juice under sterile conditions, ensuring a longer shelf life without the need for refrigeration. The packaged juice is then ready for distribution to stores and supermarkets.

Throughout the production process, rigorous quality control measures are in place to ensure the final product meets high standards of taste, color, and nutritional value. Continuous monitoring and testing at various stages help maintain product consistency and safety.

The production of orange juice is a carefully controlled process that ensures the final product is safe, nutritious, and delicious. By leveraging advanced technology and rigorous quality control measures, modern orange juice production facilities can efficiently produce high-quality products that meet global demand. From the orchard to the bottle, every step is meticulously executed to bring this refreshing beverage to consumers worldwide.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of orange juice production process Machines.Please contact us now, and our professional technical engineers will customize the equipment plan for orange juice production process and provide a quotation.Please contact us now to obtain the latest equipment plan and quotation.