A chocolate melting tank is a piece of equipment used in the chocolate manufacturing process. It is designed to melt large quantities of chocolate at a controlled temperature for various applications, such as coating, molding, or enrobing.

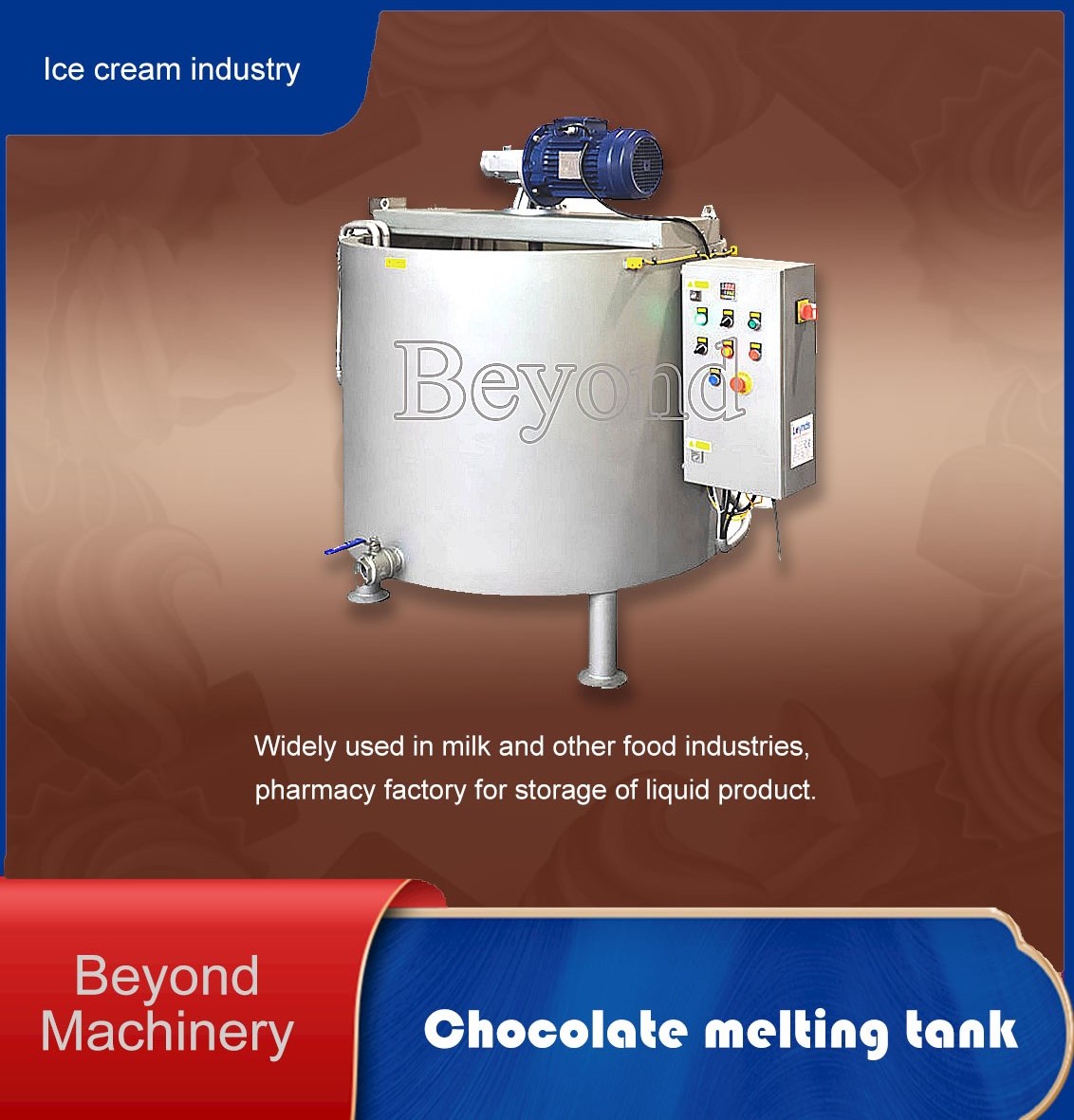

The tank consists of a large stainless steel vessel with a heating element or steam jacketed system to provide indirect heat for melting the chocolate. It typically has a capacity ranging from a few hundred kilograms to several tons of chocolate, depending on the production requirements.

The temperature in the tank is carefully monitored and controlled to ensure that the chocolate melts evenly and remains in a liquid state without burning or overheating. Some tanks may also have agitation systems to help facilitate the melting process and prevent solidification or separation.

Chocolate melting tanks may also be equipped with additional features such as temperature probes, digital controls, and safety mechanisms to ensure optimal performance and operator safety. They are commonly used in commercial chocolate factories, bakeries, confectioneries, and other food processing facilities where large-scale chocolate production is undertaken.

Use:

Mainly used to melting and later aging;widely used in ice cream and other food industry; this tank adopts electric heating and control panel which is much easy to operate.

Technical parameters:

It Can be used to melt chocolate;with scraper on the agitator where contact with the inner shell, the scraper can prevent the chocolate being sticked on the inner shell;The top cover is removable, which make it easy to load the product;With electrical control box to control the temperature and keep it at a certain degree.Material: SUS304 stainless steel or SUS316L stainless steel,this is up to the requirements from customer.

Structures and features:

1.Made of SUS304 stainless steel;

2.With PU as insulation;

3.Heated by hot water in jacket;

4.Temperature is fully automaticly controlled;

5.Volume: 75L-150L-2000L etc(according to customer requirements);

Manhole, breath valve, CIP spraying balls, lifting hooks, glass tube level indicator, digital

Show themometer, product inlet and outlet.

External surface is 2B,weld ground and clean by chemical,internal polish to mirrow or 180 mesh, this is according to client detail requirements.mixer can be made with supporter at bottom or just hanging without supporter.

Standard sizes are 500L-100,000L.

We can design the exact structure according to client detail requirements.

|

Model

|

Volume (L)

|

Power(KW)

|

Weight(kg)

|

Dimension(mm)

|

|

BYQKLG 100

|

100

|

1.1

|

150

|

Φ700*1250

|

|

BYQKLG 300

|

300

|

1.1

|

180

|

Φ900*1250

|

|

BYQKLG 500

|

500

|

1.5

|

200

|

Φ1000*1380

|

|

BYQKLG 1000

|

1000

|

2.2

|

600

|

Φ1220*1850

|