A milk silo is a specialized type of storage tank used in the dairy industry for storing and handling milk. These silos are designed to store large quantities of milk in a safe and hygienic manner.

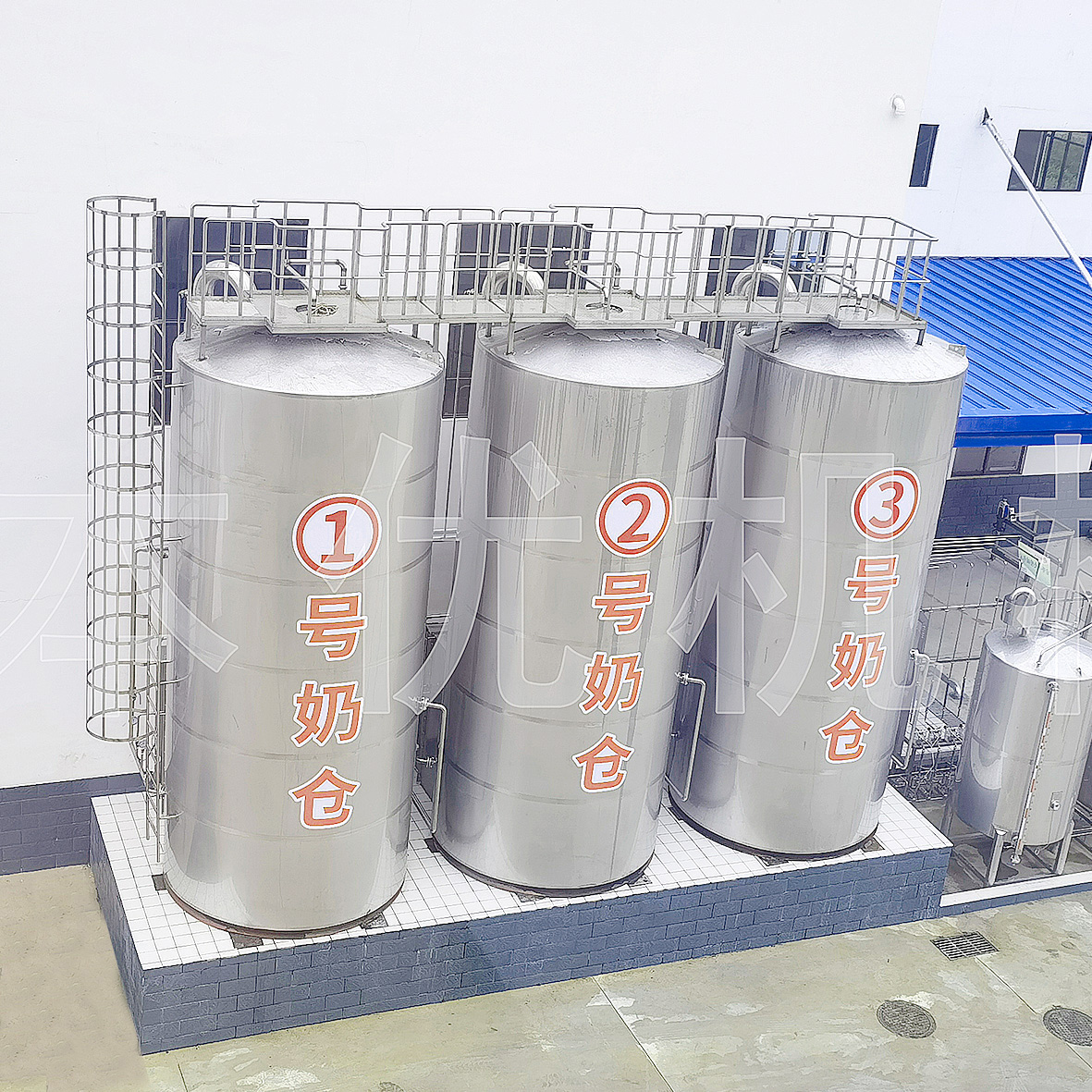

Milk silos are typically made of stainless steel, which is easy to clean, resistant to corrosion, and non-reactive to the milk's components. They are cylindrical in shape and can vary in size, from small tanks used on dairy farms to large industrial silos used in milk processing plants.

The main purpose of a milk silo is to provide a controlled environment for storing raw milk before it undergoes further processing. The silo helps to maintain the milk's freshness and quality by keeping it at a consistent temperature and protecting it from contamination.

Milk silos are equipped with various features to ensure proper storage and handling of the milk. These include insulation to maintain the desired temperature, agitation systems to prevent cream separation, and sanitary fittings for easy cleaning and maintenance.

In larger milk processing facilities, milk silos are often connected to automated milk collection systems, where milk is directly transferred from the collection trucks to the silos. This helps to streamline the milk handling process and maintain hygiene standards.

Overall, milk silos play a crucial role in the dairy industry by providing efficient and safe storage solutions for raw milk. They help ensure that milk is stored in optimal conditions, preserving its quality and freshness until it is ready for further processing or distribution.

Usage:

Applicable for large milk collection center, or for milk outdoor storage at large milk production plant; also used at other food and pharmacy factory for storage of liquid product.

This equipment is equipped with cleaning system, agitator, sight and view devices, also have attachments of thermometer and level indication meter.

Specifications:

Material: all material used is high quality sus304-2B stainless steel or SUS 316, inner shell δ=3-4mm and out shell δ=2mm and cooling jacket δ=1.5mm;

Structure: cylindrical shape, conical top cover of 15 degree, with skirt base; with PU(Polyurethane) as heat insulation; with cooling dimple pad at tank wall and base.

Volume range: 10,000L-120,000L

Standard configuration:

a). One air tight side manhole;b). One side mounted agitator at the bottom;

c). One PT100 thermometer, temperature range 0~100ºC;

d). Two CIP cleaning balls;

e). One aseptic sample valve;

f). Anti butterfly and dirt air vent;

g). Product inlet/outlet;

h). Cooling medium inlet/outlet;

i). Level sensor;

j). Ladder with circle protection and protection fence at tank top

Technical:

|

Model |

Effective volume(L) |

External diameter(mm) |

Total height(mm) |

Heat insulation layer(mm) |

Diameter of inlet/outlet |

Motor Power (kw) |

Side agitator speed(rpm) |

|

BYCG-15 |

15000 |

2200 |

6500 |

100 |

φ51 |

5.5 |

960rpm |

|

BYCG-20 |

20000 |

2380 |

7150 |

100 |

φ51 |

5.5 |

960rpm |

|

BYCG-30 |

30000 |

2700 |

7850 |

100 |

φ51 |

5.5 |

960rpm |

|

BYCG-50 |

50000 |

3200 |

9200 |

100 |

φ51 |

5.5 |

960rpm |

|

BYCG-60 |

60000 |

3400 |

9800 |

100 |

φ51 |

5.5 |

960rpm |

|

BYCG-100 |

100000 |

3620 |

12990 |

100 |

φ51 |

5.5×2 |

960rpm |

|

BYCG-120 |

120000 |

3700 |

14200 |

100 |

φ51 |

5.5×2 |

960rpm |

When it comes to customizing large outdoor storage tanks, there are several key aspects to consider that ensure the tank meets specific requirements for various applications. Here’s a detailed breakdown of the customization options available:

Installation services may include site preparation assistance if required.