The global dairy industry faces increasing demands for higher production efficiency, stricter food safety standards, and more sustainable operations. Modernizing pasteurized milk production lines has become imperative for dairy processors to remain competitive while meeting evolving consumer expectations for quality and safety. This technical article explores an integrated modernization solution centered around Shanghai Beyond Machinery's advanced production line equipment, which combines cutting-edge automation, intelligent process control, and hygienic design principles to transform traditional pasteurized milk operations into state-of-the-art facilities.

Shanghai Beyond Machinery, a leading Chinese manufacturer of dairy processing equipment, has emerged as a key provider of complete pasteurized milk production solutions. With expertise spanning milk reception, processing, homogenization, pasteurization, and packaging, Beyond's systems incorporate the latest technological advancements while maintaining cost-effectiveness—a critical factor for dairy processors in competitive markets. Their equipment portfolio ranges from small-scale operations to large industrial lines capable of processing over 50,000 liters per hour.

This article will systematically examine the modernization approach through several key dimensions: automated process control systems that enhance precision and consistency; hygienic equipment design that minimizes contamination risks; energy recovery technologies that reduce operational costs; and flexible production configurations that allow manufacturers to quickly adapt to changing market demands. We will analyze specific Beyond Machinery components such as their plate heat exchangers for HTST pasteurization, intelligent CIP cleaning systems, and homogenizers that improve product quality while extending shelf life.

The modernization framework presented here draws upon real-world implementations where Beyond-equipped facilities have achieved 30-50% improvements in production efficiency, 20-30% reductions in energy consumption, and significant enhancements in product safety and consistency. By adopting such comprehensive solutions, dairy processors can transform aging production lines into agile, high-performance operations capable of meeting both current and future industry challenges.

Pasteurized milk production presents unique technical challenges that modernization efforts must address to achieve optimal results. The combination of stringent safety requirements, delicate nutritional preservation needs, and short shelf-life constraints creates a complex operational environment where even minor inefficiencies can have significant quality and cost implications.

**Microbiological risks** represent perhaps the most persistent challenge in pasteurized milk operations. Unlike ultra-high temperature (UHT) processing which achieves commercial sterility, pasteurization (typically 72-75°C for 15-20 seconds) only reduces pathogenic microorganisms to safe levels while preserving milk's fresh characteristics. This leaves the product susceptible to post-processing contamination and spoilage organism growth, particularly psychrotrophic bacteria that thrive at refrigeration temperatures. Studies show that raw milk containing >10⁴ CFU/mL of Pseudomonas spp. can lead to bitter flavor development in 35% of finished products, while airborne mold spores in filling areas exceeding 50 CFU/m³ increase contamination rates by 40% . Biofilm formation in pipelines represents another critical concern, with some facilities experiencing 8% rejection rates due to biofilm-derived microbial contamination .

Energy intensity stands as another major challenge, with traditional pasteurization processes consuming substantial thermal energy for heating and cooling. The typical HTST (High Temperature Short Time) pasteurization process requires heating milk from ~4°C to 72-75°C, followed by immediate cooling back to 4-6°C—a sequence that represents one of the most energy-intensive steps in dairy processing. Without modern heat recovery systems, this thermal cycling results in significant energy waste and elevated production costs.

- Inconsistent pasteurization parameters that affect both safety and quality

- Excessive product losses during changeovers and startups

- High labor requirements for operation and cleaning

- Difficulty in tracing and addressing quality deviations

- Limited flexibility to adjust production parameters for different product specifications

Shelf-life limitations imposed by the pasteurization process itself create additional pressures on production and distribution logistics. With typical shelf lives of 7-15 days under proper refrigeration, pasteurized milk demands exceptionally efficient production scheduling, inventory management, and cold chain maintenance—all areas where modernized operations can provide substantial improvements.

Shanghai Beyond Machinery's modernization approach specifically targets these challenges through integrated technological solutions that enhance both performance and reliability. Their systems incorporate advanced materials, intelligent automation, and energy-efficient designs that collectively address the core pain points of pasteurized milk production while maintaining the nutritional and sensory qualities that distinguish pasteurized products from shelf-stable alternatives.

Shanghai Beyond Machinery offers a comprehensive modernization package for pasteurized milk production that addresses all critical aspects of dairy processing through technologically advanced, yet practical equipment solutions. Their integrated approach combines high-efficiency thermal processing, precision automation, and hygienic design principles to create production lines that outperform traditional systems in both performance and reliability.

The foundation of Beyond's modernization solution lies in its carefully engineered core components, each designed to maximize processing efficiency while maintaining product quality:

1. **Intelligent Pasteurization Systems**: At the heart of the production line, Beyond's plate heat exchangers for HTST pasteurization feature advanced thermal designs that achieve optimal heat transfer efficiency while minimizing pressure drops. Their multi-section configurations allow for regenerative heating that can recover up to 90% of thermal energy, dramatically reducing energy consumption compared to conventional systems . The pasteurizers incorporate precision temperature control systems that maintain parameters within ±0.5°C of set points, ensuring consistent treatment while preserving milk's nutritional properties.

2. **Homogenization Technology**: Beyond's high-pressure homogenizers (operating at 150-250 bar) utilize specially designed valve technologies that achieve superior fat globule dispersion while reducing energy requirements by 15-20% compared to conventional models. This results in improved product stability, enhanced mouthfeel, and extended shelf life—critical factors for pasteurized milk competing in quality-conscious markets .

3. **Automated CIP (Clean-in-Place) Systems**: Recognizing that hygiene is paramount in pasteurized milk production, Beyond's intelligent CIP systems automate the entire cleaning and sanitation process with programmable sequences for pre-rinse, alkaline wash, acid wash, and final rinse. Their patented nozzle designs and optimized flow dynamics ensure complete surface coverage in tanks and pipelines, while integrated conductivity and temperature sensors verify cleaning effectiveness in real-time .

Beyond's modernization solution incorporates a sophisticated automation architecture that elevates process control to unprecedented levels of precision and reliability:

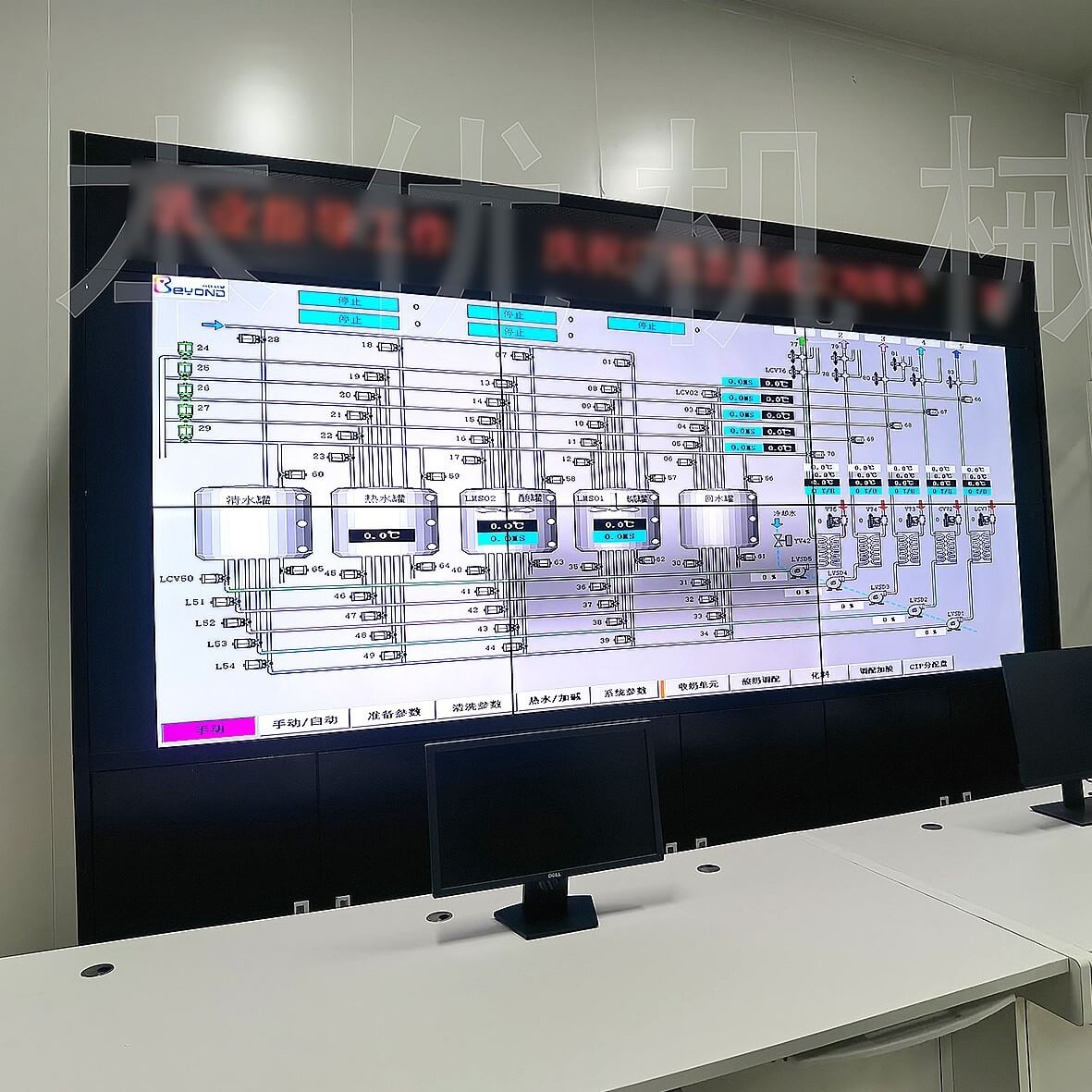

- **PLC/SCADA Integration**: The system utilizes modular PLC controllers (Siemens or Rockwell platforms) networked with SCADA supervisory systems to provide comprehensive monitoring and control of all critical parameters—temperature, pressure, flow rates, product composition, and equipment status. This distributed control architecture ensures rapid response to any process deviations while maintaining complete data traceability .

- **Adaptive Process Optimization**: Beyond basic control, Beyond's systems employ advanced algorithms that continuously optimize process parameters based on real-time conditions. For pasteurization, this includes dynamic adjustment of heating rates and holding times based on incoming milk composition and flow variations, ensuring consistent treatment quality despite raw material fluctuations .

- **Predictive Maintenance Capabilities**: By monitoring vibration, temperature, and performance trends in rotating equipment like pumps and homogenizers, the system can predict potential failures before they occur, scheduling maintenance during planned downtime to avoid unexpected production interruptions .

Every component in Beyond's pasteurized milk line adheres to strict hygienic design principles that minimize contamination risks and facilitate effective cleaning:

- **Surface Finishes**: All product contact surfaces feature Ra ≤ 0.8 μm finishes, exceeding EHEDG and 3-A Sanitary Standards requirements for dairy equipment. This ultra-smooth surface topography prevents bacterial adhesion and enables more effective cleaning .

- **Drainability**: Equipment designs ensure complete drainage with no liquid traps or dead zones where product or cleaning solutions could accumulate. Beyond's tanks and processing vessels feature sloped bottoms (minimum 3° incline) and radiused corners that promote complete drainage .

- **Material Selection**: Austenitic stainless steel (316L grade) is standard for all product contact surfaces, providing excellent corrosion resistance and cleanability. For specific applications requiring enhanced durability, Beyond offers optional surface treatments like electropolishing or specialized coatings .

By integrating these advanced technologies with robust engineering, Shanghai Beyond Machinery's pasteurized milk production solutions provide dairy processors with a clear path to modernized operations that deliver superior quality, efficiency, and operational reliability. The following sections will examine specific technological innovations that enable these performance improvements in greater detail.

Shanghai Beyond Machinery's pasteurized milk production solutions incorporate several groundbreaking technological innovations that collectively address the core challenges of modern dairy processing. These advancements span thermal efficiency, contamination control, process automation, and system flexibility—each contributing to measurable improvements in production performance and product quality.

Beyond's pasteurization systems feature an innovative multi-stage heat recovery design that sets new benchmarks for energy efficiency in dairy processing:

1. **Regenerative Heating Technology**: The heart of the system lies in its sophisticated plate heat exchanger configuration that recovers thermal energy from pasteurized milk to preheat incoming raw product. This regenerative heating typically achieves 90-94% heat recovery efficiency, reducing energy requirements for pasteurization by 35-40% compared to conventional systems without regeneration . The multi-section design allows precise temperature control at each stage, preventing overheating that could compromise milk quality.

2. **Intelligent Energy Management**: Integrated energy optimization algorithms continuously analyze process conditions to maximize heat recovery. The system dynamically adjusts flow patterns and heat transfer surfaces based on real-time monitoring of milk composition, flow rates, and temperature differentials. This adaptive approach maintains optimal efficiency even during production rate changes or product transitions .

3. **Waste Heat Utilization**: Beyond regenerative heating, Beyond's systems capture and repurpose waste heat from various processes. For example, heat recovered from cooling pasteurized milk can be redirected to preheat cleaning water or maintain hot water reserves for CIP systems, creating additional energy savings of 8-12% .

Recognizing that biofilm formation in pipelines represents a persistent challenge in dairy processing, Beyond has developed a comprehensive approach to biofilm prevention and control:

1. **Surface Engineering**: All product contact surfaces undergo specialized electropolishing treatments that reduce surface roughness to Ra ≤ 0.4 μm, creating an inhospitable environment for bacterial attachment and biofilm initiation . Critical areas like pipe joints and valve bodies feature enhanced designs that eliminate crevices and dead zones where biofilms typically originate.

2. **CIP Optimization**: Beyond's advanced CIP systems incorporate several innovations for biofilm control:

- **Dual-action cleaning nozzles** that combine high-impact mechanical cleaning with optimized chemical dispersion

- **Variable flow programming** that creates turbulent flow patterns (Re > 3000) throughout the entire pipeline network

- **Silver-ion enhanced cleaning solutions** that penetrate and disrupt biofilm matrices, achieving 99.99% biofilm removal efficiency when integrated with standard alkaline-acid cleaning cycles

3. **Real-time Monitoring**: Integrated sensors measure ATP levels and microbial activity on surfaces, providing quantitative feedback on cleaning effectiveness. This data drives adaptive CIP programming that automatically adjusts cleaning parameters based on actual conditions rather than fixed schedules .

Beyond's production lines employ a sophisticated automation framework that transforms traditional pasteurized milk operations into smart, data-driven processes:

1. **Distributed Control System**: The architecture features decentralized intelligence with:

- **Edge controllers** at each major equipment node for rapid, localized decision-making

- **Centralized SCADA** for system-wide monitoring and optimization

- **Cloud connectivity** for remote access and data analytics

2. **Adaptive Process Control**: Machine learning algorithms analyze historical and real-time process data to continuously refine control parameters. For pasteurization, this includes:

- Dynamic adjustment of temperature setpoints based on milk composition and flow variations

- Predictive modeling of heat exchanger performance to maintain optimal thermal profiles

- Automatic compensation for fouling trends in heat transfer surfaces

3. **Digital Twin Integration**: Selected Beyond systems offer digital twin capability, creating virtual replicas of the physical production line. This enables:

- Process simulation and optimization before implementation

- Operator training in virtual environments

- Predictive maintenance modeling based on equipment wear patterns

Modular Production Design

To address the growing need for manufacturing flexibility, Beyond's solutions incorporate modular design principles that enable rapid reconfiguration for different products or production scenarios:1. **Plug-and-Play Modules**: The production line is organized into standardized, pre-validated processing modules (e.g., separation, standardization, pasteurization, homogenization) that can be quickly rearranged or swapped . This modularity reduces changeover time by up to 70% compared to traditional fixed-configuration systems.

2. **Multi-product Capability**: A single Beyond line can be configured to produce various pasteurized milk products including:

- Standard whole/skim/low-fat milk

- Fortified milk (vitamin/protein enriched)

- Flavored milk varieties

- Lactose-free formulations

3. **Scalable Capacity**: The modular design allows for capacity expansion through parallel module addition rather than complete line replacement. Production rates can be incrementally increased by 25%, 50%, or 100% with minimal disruption to existing operations .

These technological innovations collectively position Shanghai Beyond Machinery's solutions at the forefront of pasteurized milk production modernization. By addressing energy efficiency, contamination control, process intelligence, and operational flexibility in an integrated manner, Beyond equipment provides dairy processors with a comprehensive platform for achieving sustainable competitive advantage in increasingly demanding markets.

Successful modernization of a pasteurized milk production line requires careful planning and phased execution to minimize disruption while maximizing the benefits of new technologies. Shanghai Beyond Machinery has developed a structured implementation approach based on numerous successful dairy plant upgrades, ensuring smooth transition from legacy systems to advanced automated production.

Phase 1: Comprehensive Facility Assessment

The modernization journey begins with a thorough evaluation of existing operations to identify improvement opportunities and establish baseline metrics:1. **Process Mapping and Bottleneck Analysis**:

- Detailed mapping of current milk flow from reception to packaging

- Identification of capacity constraints and inefficiencies

- Evaluation of equipment condition and performance gaps

2. **Quality and Safety Audit**:

- Review of microbial test results and quality deviations

- Assessment of hygiene practices and CIP effectiveness

- Identification of contamination risks throughout the process

3. **Energy and Resource Utilization Study**:

- Measurement of thermal and electrical energy consumption

- Evaluation of water usage and waste generation

- Identification of energy recovery opportunities

4. **Automation and Data Infrastructure Review**:

- Assessment of current control systems and instrumentation

- Evaluation of data collection and analysis capabilities

- Identification of manual processes suitable for automation

This assessment phase typically takes 2-4 weeks and results in a detailed gap analysis report with specific recommendations for modernization priorities. Beyond's engineering team works closely with plant personnel during this phase to ensure all operational nuances are considered .

Based on the assessment findings, Beyond develops a tailored modernization plan that addresses the specific needs and constraints of each facility:

1. **Process Flow Optimization**:

- Redesign of milk flow paths to minimize hold-up volume and residence time

- Integration of new technologies with existing infrastructure

- Planning for future expansion requirements

2. **Equipment Specification and Layout**:

- Selection of appropriate pasteurizer size and configuration

- Determination of homogenization and cooling requirements

- Development of detailed equipment layouts and piping diagrams

3. **Automation Architecture Design**:

- Specification of control system hardware and software

- Design of human-machine interface (HMI) screens

- Development of data collection and reporting protocols

4. **Hygiene and Safety Integration**:

- Incorporation of biofilm prevention features

- Design of CIP and sanitation protocols

- Integration of food-grade safety systems

The design phase typically takes 4-8 weeks and includes multiple review cycles with plant personnel to ensure the proposed solution meets all operational requirements. Beyond provides detailed 3D models and simulation tools to help visualize the modernized production line before implementation .

To minimize production disruption, Beyond recommends a phased implementation approach that allows for continuous operation during modernization:

1. **Pilot System Installation**:

- Initial deployment of a single processing module (e.g., new pasteurization section)

- Parallel operation with existing equipment for comparison

- Staff training on new technologies and procedures

2. **Core System Upgrade**:

- Installation of main processing equipment during planned downtime

- Integration with existing utilities and ancillary systems

- Commissioning and performance verification

3. **Ancillary System Integration**:

- Installation of CIP and utility support systems

- Connection to automation and control infrastructure

- Final testing and optimization

The implementation timeline varies depending on plant size and complexity, but typically ranges from 8-16 weeks for complete modernization. Beyond's project management team coordinates all aspects of the installation to ensure adherence to schedule and budget .

Following installation, comprehensive validation ensures the modernized line meets all performance targets:

1. **Operational Qualification (OQ)**:

- Verification of all system functions under normal operating conditions

- Testing of safety interlocks and alarm systems

- Validation of automated sequences and control logic

2. **Performance Qualification (PQ)**:

- Extended production runs to verify consistent quality

- Measurement of key performance indicators (KPIs)

- Comparison against baseline metrics from legacy systems

3. **Continuous Improvement**:

- Fine-tuning of process parameters based on operational data

- Adjustment of automation algorithms for optimal performance

- Implementation of predictive maintenance programs

Beyond provides ongoing support during this phase, including operator training programs and performance monitoring services. The company's remote diagnostics capabilities allow for real-time support and troubleshooting as needed .

Successful modernization requires careful attention to organizational and human factors:

1. **Workforce Training**:

- Comprehensive training programs for operators, maintenance staff, and supervisors

- Virtual reality simulations for complex procedures

- Certification programs for critical operations

2. **Process Documentation**:

- Development of detailed standard operating procedures (SOPs)

- Creation of maintenance manuals and troubleshooting guides

- Documentation of system specifications and validation records

3. **Performance Monitoring**:

- Establishment of key performance indicators (KPIs)

- Implementation of dashboard reporting tools

- Regular performance review meetings

By following this structured implementation strategy, dairy processors can achieve a smooth transition to modernized pasteurized milk production with minimal disruption to ongoing operations. Shanghai Beyond Machinery's experience across numerous installations ensures that potential challenges are anticipated and addressed proactively, resulting in successful outcomes that deliver measurable improvements in quality, efficiency, and profitability .

Real-world implementations of Shanghai Beyond Machinery's pasteurized milk production solutions demonstrate the tangible benefits achievable through comprehensive modernization. These case studies, drawn from various dairy processing facilities across Asia, highlight measurable improvements in productivity, quality, and operational efficiency following the adoption of Beyond's advanced technologies.

**Background**: A major dairy cooperative processing approximately 200,000 liters of pasteurized milk daily sought to modernize its aging production line to improve energy efficiency and extend product shelf life.

- Installation of Beyond's HTST pasteurization system with 94% heat recovery efficiency

- Implementation of intelligent CIP system with biofilm control technology

- Integration of advanced automation and process control architecture

Performance Improvements:

| Metric | Before Modernization | After Modernization | Improvement ||--------|----------------------|---------------------|-------------|

| Energy Consumption | 0.48 kWh/liter | 0.32 kWh/liter | 33% reduction |

| Product Shelf Life | 10 days | 14 days | 40% extension |

| Microbial Rejection Rate | 3.2% | 0.8% | 75% reduction |

| Daily Production Capacity | 180,000 L | 220,000 L | 22% increase |

| CIP Water Usage | 8,000 L/day | 5,200 L/day | 35% reduction |

**Key Outcomes**: The modernization project achieved payback within 2.3 years through combined energy savings and increased production capacity. The extended shelf life provided significant distribution advantages, allowing access to more distant markets .

**Background**: A medium-sized processor (50,000 L/day) supplying premium pasteurized milk to urban markets needed to upgrade its facility to meet stricter food safety standards while maintaining product quality characteristics.

**Modernization Highlights**:

- Implementation of Beyond's complete pasteurized milk line including separation, standardization, and homogenization

- Installation of advanced process analytics and quality monitoring systems

- Adoption of modular production design for multi-product flexibility

**Performance Improvements**:

| Metric | Before Modernization | After Modernization | Improvement |

|--------|----------------------|---------------------|-------------|

| Labor Requirements | 12 operators/shift | 8 operators/shift | 33% reduction |

| Changeover Time | 90 minutes | 25 minutes | 72% reduction |

| Fat Standardization Accuracy | ±0.3% | ±0.1% | 67% improvement |

| Product Consistency (viscosity CV) | 8.5% | 3.2% | 62% improvement |

| Utility Costs | $0.082/L | $0.061/L | 25.6% reduction |

**Key Outcomes**: The precision standardization and homogenization capabilities allowed the processor to command premium pricing for its consistently high-quality products. The labor savings and reduced changeover times significantly improved operational efficiency .

**Background**: A small organic dairy (15,000 L/day) specializing in minimally processed pasteurized milk sought to maintain its artisanal quality while improving production efficiency and shelf life.

**Modernization Highlights**:

- Custom-designed gentle processing system with precise temperature control

- Specialized CIP system for organic cleaning requirements

- Integrated quality monitoring with blockchain traceability

**Performance Improvements**:

| Metric | Before Modernization | After Modernization | Improvement |

|--------|----------------------|---------------------|-------------|

| Vitamin Retention (B12) | 82% | 91% | 11% improvement |

| Sensory Quality Score | 8.1/10 | 8.7/10 | 7.4% improvement |

| Production Yield | 92.5% | 96.8% | 4.6% improvement |

| Energy Use per Liter | 0.52 kWh | 0.41 kWh | 21% reduction |

| Customer Complaints | 3.2/month | 0.9/month | 72% reduction |

**Key Outcomes**: The modernized line successfully preserved the delicate sensory characteristics valued by organic consumers while delivering measurable improvements in nutritional retention and operational efficiency. The blockchain traceability system enhanced brand transparency and consumer trust .

Across multiple installations, Shanghai Beyond Machinery's pasteurized milk production solutions have consistently delivered significant improvements in key performance indicators:

**Product Quality Metrics**:

- 30-45% extension in product shelf life through improved processing and homogenization

- 50-70% reduction in microbial counts in finished products

- 20-30% improvement in nutritional retention (particularly heat-sensitive vitamins)

**Operational Efficiency Metrics**:

- 25-40% reduction in energy consumption through advanced heat recovery

- 30-50% decrease in water usage via optimized CIP systems

- 20-35% increase in production capacity from improved line efficiency

- 60-75% faster product changeovers with modular system design

**Economic Performance Metrics**:

- 12-30 month typical payback periods for complete modernization projects

- 15-25% reduction in production costs per liter

- 3-5% increase in product yield from reduced losses

These case studies demonstrate that Shanghai Beyond Machinery's comprehensive approach to pasteurized milk production modernization delivers measurable benefits across all aspects of dairy processing—from product quality and safety to operational efficiency and economic performance. The flexibility of Beyond's solutions allows for customization to various production scales and market requirements, making advanced dairy processing technology accessible to processors of all sizes .

The modernization of pasteurized milk production lines represents a critical imperative for dairy processors seeking to remain competitive in an industry characterized by rising quality expectations, stringent safety requirements, and increasing cost pressures. As demonstrated throughout this technical analysis, Shanghai Beyond Machinery's integrated solutions provide a comprehensive pathway to achieving these operational goals through advanced engineering, intelligent automation, and innovative processing technologies.

The Beyond modernization approach delivers transformative improvements across all critical aspects of pasteurized milk production:

1. **Enhanced Product Quality and Safety**:

- Extended shelf life through precise thermal processing and superior homogenization

- Reduced contamination risks via advanced hygienic design and biofilm prevention

- Improved nutritional retention with gentle, controlled processing parameters

2. **Operational Efficiency Gains**:

- Significant energy savings from high-efficiency heat recovery systems

- Reduced water and chemical consumption through optimized CIP processes

- Increased production capacity via streamlined flow and reduced downtime

3. **Economic Performance Improvements**:

- Rapid return on investment from energy and resource savings

- Higher production yields and reduced product losses

- Labor productivity gains through automation and reduced manual intervention

4. **Strategic Flexibility**:

- Modular design enabling quick adaptation to changing market demands

- Scalable architecture supporting future expansion needs

- Multi-product capability for diversified production

Industry Trends and Future Developments

Looking ahead, several emerging trends are shaping the future of pasteurized milk production technology, with Shanghai Beyond Machinery well-positioned to address these developments:1. **Digital Transformation**:

- Expanded adoption of Industry 4.0 technologies including digital twins and AI-driven process optimization

- Enhanced connectivity for real-time quality monitoring and predictive maintenance

- Blockchain integration for complete supply chain transparency

2. **Sustainability Innovations**:

- Development of net-zero energy dairy processing through renewable integration

- Advanced water recycling and waste reduction technologies

- Low-GWP refrigerant systems for cooling operations

3. **Advanced Processing Technologies**:

- Non-thermal preservation methods complementing pasteurization

- Precision fermentation for customized milk composition

- Smart packaging with freshness indicators

4. **Customization and Personalization**:

- Flexible systems enabling small-batch production of specialized formulations

- Direct-to-consumer production models with rapid product changeovers

- Nutrigenomic-based product customization

Strategic Recommendations

For dairy processors considering production line modernization, the following strategic recommendations emerge from this analysis:1. **Holistic Assessment**:

- Conduct comprehensive audits of current operations to identify priority improvement areas

- Consider both immediate needs and long-term strategic objectives

- Evaluate modernization options against total cost of ownership rather than just capital cost

2. **Phased Implementation**:

- Prioritize core process improvements with fastest returns (typically pasteurization and heat recovery)

- Follow with automation and control system upgrades

- Complete with ancillary system improvements and staff training

3. **Technology Partnerships**:

- Collaborate with experienced suppliers like Shanghai Beyond Machinery for integrated solutions

- Leverage vendor expertise in system design and implementation

- Utilize ongoing technical support and optimization services

4. **Workforce Development**:

- Invest in training programs for new technologies and processes

- Foster culture of continuous improvement and data-driven decision making

- Develop maintenance competencies for advanced equipment

Final Perspective

The pasteurized milk sector continues to represent a vital segment of the global dairy industry, valued by consumers for its fresh taste and nutritional profile. Shanghai Beyond Machinery's modernization solutions provide dairy processors with the tools to preserve these valued characteristics while meeting the demands of modern food production—superior safety, operational efficiency, and environmental responsibility.As consumer expectations evolve and competitive pressures intensify, the strategic modernization of pasteurized milk production lines will increasingly differentiate market leaders from followers. Through its combination of advanced engineering, practical innovation, and comprehensive support, Shanghai Beyond Machinery has established itself as a valuable partner in this essential industry transformation.

The case studies and performance metrics presented in this analysis demonstrate that thoughtful, well-executed modernization projects can deliver compelling returns while future-proofing dairy operations against emerging challenges. For processors committed to excellence in pasteurized milk production, the path forward is clear: embrace technological innovation through partnerships with proven leaders like Shanghai Beyond Machinery, and reap the rewards of efficient, sustainable, high-quality milk production for years to come .