Description:

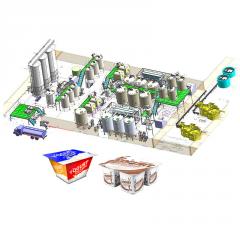

A milk processing line refers to a series of equipment and machinery used in the production and processing of milk. It typically includes various steps such as milk reception, pasteurization, homogenization, separation, sterilization, and packaging.

Here are some key components commonly found in a milk processing line:

Milk reception: This stage involves receiving and testing the incoming raw milk to ensure its quality and safety.

Pasteurization: Raw milk is heated to a specific temperature for a set period to destroy harmful bacteria and extend its shelf life.

Homogenization: In this step, milk is passed through a high-pressure homogenizer to break down fat globules and create a uniform texture.

Separation: The milk is separated into cream and skim milk using a centrifuge, which removes the cream for further processing.

Sterilization: Depending on the desired shelf life and the final product, milk may be further processed through methods such as ultra-high temperature (UHT) treatment or aseptic packaging.

Packaging: The final stage involves filling the processed milk into appropriate containers, such as cartons, bottles, or bags, and sealing them for distribution.

Shanghai beyond machinery co., ltd is specialized in supplying various kinds of milk processing line, including the pasteurized milk, UHT milk, flavored milk, yoghurt, cheese and butter, cream, condensed milk etc.

Shanghai Beyond can supply complete turnkey projects for customers, integrating with designing, equipment manufacturing, to installation and commissioning and also training the operators.

Large type central control system: Full-auto material system、Full-auto blending system、Full-auto CIP system、Automatic online mixing system、Full-auto material dissolving system、Full-auto valve system、Full-auto valve system.

Milk process: milk transporting tank or vessels, milk filter and collection tank; cooling and storaging tank(milk chilly tank), Mixing/Blending and milk standardization, cream separation, UHT sterilizer(tubular type or plate type) homogenization, degassing, and filling.

Features and advantages:

1. Processing capacity can be ranged from 2T/Day to 1000T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line equipments meet food sanitary safety requirements.

5. Whole line with features as high level automatic, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

Output: 20 t/d--500 t/d

Milk Production Line Raw Materials and Products

1. Raw Materials

In the milk production line, the main raw material is raw milk, as well as other possible additives and auxiliary materials. The following is a detailed list of raw materials:

•Raw milk: fresh milk directly obtained from dairy farms or pastures, is the basic raw material in the production process. The quality of raw milk directly affects the quality of the final product.

•Water: used for dilution, cleaning equipment and cooling process.

•Emulsifiers: such as lecithin, used to improve the stability and taste of the product.

•Stabilizers: such as carrageenan and gelatin, used to prevent product stratification and improve the texture of the product.

•Sweeteners: such as sucrose and stevia, used to increase the sweetness of the product.

•Flavors: such as vanilla flavor, used to enhance the flavor of the product.

•Vitamins and minerals: such as vitamin D and calcium, used to enhance the nutritional value of the product.

•Preservatives: such as potassium sorbate, used to extend the shelf life of the product.

2. Products

The milk production line can produce a variety of different products. The following are some common product types:

•Whole milk: retains all the fat in the milk, has a rich taste and is rich in nutrition.

• Low-fat milk: removes part of the fat through centrifugal separation technology, suitable for people pursuing a low-fat diet.

• Skim milk: almost fat-free, suitable for people who are losing weight and following a low-fat diet.

• Flavored milk: such as chocolate milk and strawberry milk, a variety of flavors are available by adding different flavors and sweeteners.

• Fortified milk: adds additional vitamins and minerals, such as vitamin D and calcium, to enhance nutritional value.

• Organic milk: from cows on organic farms, produced in accordance with organic farming standards, without chemical pesticides and hormones.

• Plant-based milk: such as soy milk, almond milk, oat milk, suitable for lactose intolerant or vegetarians.

• Yogurt: a milk product produced through fermentation technology, containing probiotics, which helps digestion and intestinal health.

• Cream: a high-fat dairy product extracted from milk, often used in cooking and baking.

• Cheese: a solid or semi-solid dairy product made through a coagulation and fermentation process, with a wide variety and different flavors.

Milk Production Line Main Equipment On the milk production line, the coordinated use of various equipment is the key to ensure the efficiency of the production process and product quality. The following are the main equipment and their functions commonly found in the milk production line:

1. Raw milk receiving and inspection equipment

• Milk storage tank: used to temporarily store raw milk transported from the pasture.

• Filter: remove impurities and large particles in raw milk.

• Centrifuge: used to remove impurities and fat separation in raw milk and adjust the fat content.

2. Pretreatment equipment

• Standardization system: by adding or removing fat, the raw milk reaches the required fat content.

• Preheater: preheat the raw milk to the appropriate temperature to prepare for subsequent processing.

3. Homogenization equipment

• Homogenizer: breaks the fat globules in the milk into smaller particles through high pressure to prevent the fat from floating and improve the stability and taste of the product.

4. Heating and sterilization equipment

• Pasteurizer: kills most of the microorganisms in the raw milk by low temperature for a long time or high temperature for a short time.

•UHT sterilization system: through ultra-high temperature instantaneous sterilization technology, the milk is heated to above 135°C and quickly cooled to ensure thorough sterilization and extend the shelf life.

5. Cooling equipment

•Multi-stage plate heat exchanger: used to quickly cool the sterilized milk to prevent the loss of nutrients and flavor changes.

6. Filling and packaging equipment

•Aseptic filling machine: filling in a sterile environment to ensure that the product is not contaminated.

•Sealing machine: used to seal the package to ensure the sealing and shelf life of the product.

•Labeling machine: used to affix product labels containing product information and instructions for use.

•Packaging machine: pack the product into boxes for easy transportation and sales.

7. Quality control equipment

•Laboratory equipment: used to perform quality inspections on raw milk and finished products to ensure the safety and nutritional value of the product.

•Online detector: real-time monitoring of key parameters in the production process, such as temperature, pressure, flow, etc.

8. Storage and transportation equipment

•Refrigerator: used to store unopened products to ensure their quality within the shelf life.

•Transportation vehicles: Choose appropriate transportation methods and cold chain systems to ensure that products are not affected by temperature during transportation.

|

Equipment list DAIRY PRODUCTION plant (pasteurized milk\yogurt\cheese\cream\butter) |

||

| NO. | NAME | MAIN TECHNOLOGY PARAMETER |

| 1 | MILK RECEIVE\STORAGE\AND CREAM SEPARETOR UNIT | |

| 2 | Electron pound scale | maximum weighing 500KG |

| 3 | Milk weighing tank | made of SUS stainless steal,single layer,product feeded in through 40 mesh filter net,CIP cleaning ball |

| 4 | Milk acceptor | SUS304 stainless steel,single layer,CIP cleaning ball |

| 5 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 6 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 7 | Dish separator | auto residue discharge |

| 8 | Chiling tank | SUS304 stainless steel,alveolate jacket,attached with compressor |

| 9 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 10 | PREPARING UNIT | |

| 11 | Blending tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 12 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 13 | Mini set of plate-type heat exchanger | SUS304 stainless steel,two stages, |

| 14 | High speed emulsification tank | SUS304 stainless steel,heat insulated,bottom high speed emulsifier,digital readout thermometer,supporters with adjustable feet |

| 15 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 16 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 17 | Sterilizing,homogenizing unit | |

| 18 | UHT sterilizer | tub-type,sterilzing temperature 137 C,holding time 4S,full automatic control |

| 19 | High pressure homogenizer | 40MPa,(starting box included) |

| 20 | Temperature holding | SUS304,holding 300S |

| 21 | Distributing board | SUS304,3 holes |

| 22 | Cheese\butter processing unit | |

| 23 | Bufferying tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 24 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 25 | Cream seperator | |

| 26 | Bufferying container | SUS304,with cover |

| 27 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 28 | Butter-churner | SUS304,stepless timing |

| 29 | Cheese vat | SUS304,with heating jacket and insising device |

| 30 | Pressor | SUS304,6 heads |

| 31 | Mould | SUS304,10L,with cover |

| 32 | Yogurt fermentation unit | |

| 33 | Fermentation tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 34 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 35 | Plate cooler | SUS304,single stage,milk discharge at 4degreeC |

| 36 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 37 | Filling unit | |

| 38 | Higher position tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 39 | Pasteurized milk filling machine | |

| 40 | Yogurt filling machine | |

| 41 | CIP system | |

| 42 | Semi-auto CIP system | outer coat of SUS304 stainless steel material,inner shell of SUS316,single cleaning way,Concentrated acid/alcali tank adding system based on US technology, 100L×2 acid/alcali Concentrate tanks |

| 43 | CIP return pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 44 | Installation part | project installation and commissioning |

Milk Processing Line Customization Process

The process of customizing a milk processing line involves several key steps to ensure that the final product meets specific requirements and quality standards. Below is a detailed breakdown of the customized process:

1. Requirement Analysis

The first step in customizing a milk processing line is to conduct a thorough analysis of the client’s needs. This includes understanding the types of milk products they wish to produce (e.g., UHT milk, pasteurized milk, condensed milk), production capacity, and any specific quality standards or regulatory requirements that must be met.

2. Design Specifications

Based on the requirement analysis, design specifications are developed. This includes selecting appropriate equipment such as refrigerated storage tanks, joint filters, plate heat exchangers, homogenizers, pasteurizers, and cooling systems. The specifications will also detail the layout of the processing line to optimize workflow and efficiency.

3. Equipment Selection

Choosing the right equipment is crucial for achieving desired results. For instance:

Refrigerated Milk Storage Tank: Essential for cooling and storing raw milk.

Plate Heat Exchanger: Used for efficient heating and cooling processes.

Homogenizer: Ensures uniform distribution of fat globules in milk.

Pasteurizer: Critical for eliminating pathogenic microorganisms while preserving nutritional value.

4. Process Flow Design

A detailed flow diagram is created to illustrate how raw milk will move through various stages of processing. This includes filtration, preheating, homogenization, pasteurization or UHT treatment, cooling, and filling into packaging.

5. Compliance with Regulations

Ensure that all processes comply with local and international food safety regulations. This may involve incorporating features like automatic temperature control systems, recording devices for monitoring heat treatment parameters, and safety mechanisms to prevent contamination.

6. Installation and Testing

Once the design is finalized and equipment selected, installation takes place at the client’s facility. After installation, rigorous testing is conducted to ensure that all components work together seamlessly and meet production goals.

7. Training and Support

Providing training for staff on how to operate the new system efficiently is essential. Additionally, ongoing support should be offered to address any operational issues that may arise post-installation.

8. Continuous Improvement

After implementation, it’s important to monitor performance continuously and gather feedback from operators to identify areas for improvement in efficiency or product quality.

By following these steps meticulously during the customization process of a milk processing line, producers can achieve high-quality outputs tailored specifically to their market demands.