Description:

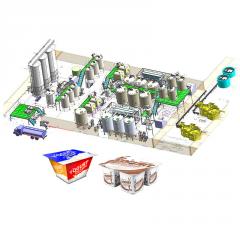

A milk powder production line is a series of machines and equipment used for producing powdered milk from fresh milk. The process typically involves the following steps:

1. Raw material preparation: select fresh and uncontaminated milk, conduct preliminary processing and inspection to ensure the quality of raw materials.

2. Standardization: adjust the fat content and protein content of milk to meet production standards.

3. Preheating: preheating milk to a certain temperature will help the subsequent concentration and sterilization process.

4. Concentration: evaporate the water in the milk through the evaporator, increase the solid content, and form concentrated milk.

5. Homogenization: break the fat globules in the concentrated milk into smaller particles through the homogenizer to prevent stratification and improve the taste.

6. Sterilization: Heat the concentrated milk to a high temperature for sterilization to ensure the safety of the product.

7. Cooling: The sterilized concentrated milk is quickly cooled to a suitable temperature to prevent bacterial growth.

8. Spray drying: The cooled concentrated milk passes through a spray drying tower to form fine milk powder particles.

9. Cooling and screening: The spray-dried milk powder is cooled to room temperature and passed through a sieve to remove large particles and impurities.

10. Mixing and seasoning (optional): Vitamins, minerals, flavors, etc. are added according to the product type.

11. Filling and sealing: The milk powder is filled into canned or bagged containers and sealed to ensure the hygiene and shelf life of the product.

12. Quality control: Sensory and laboratory tests are performed on the finished product to ensure the safety and quality of the product.

13. Storage and transportation: Store the product in a suitable environment, choose the appropriate transportation method and cold chain system to ensure that the product is not affected by temperature during transportation.

Features and advantages:

1. Processing capacity can be ranged from 1T/Day to 100T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line equipments meet food sanitary safety requirements.

5. Whole line with features as high level automatic, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

Multi effect and multi process falling film evaporator (concentrator)

Product features:

It has the characteristics of long membrane tube, multi return, large flow, less cleaning times, low energy consumption, long continuous operation time, small material heating damage, and little impact on product color, flavor and nutritional components.

This series of evaporators can be selected from the evaporation capacity of 1200kg/h to 20000kg/h according to the service capacity; According to the effect and process form, the equipment can be selected from double effect and double process, double effect and three process, three effect and seven process and four effect and nine process; Pasteurization, super pasteurization steam bath sterilization and clean steam direct injection sterilization (DSI) are optional.

Upper exhaust pressure type spray drying tower

Product features:

Upper inlet air, upper exhaust air, wide tower body, capable of primary coalescence of droplets and secondary coalescence of fine powder, and equipped with built-in fluidized bed and vibrating fluidized bed, a three-stage drying spray drying system with high and low temperature auxiliary drying and cooling functions. It is also called low temperature drying tower in the international industry.

Working principle:

The hot air quickly converges with the spray droplets under the protection of the annular wind curtain through the diversion hot air distributor, so that the droplets vaporize in 0.4 seconds. The pressure of the hot air makes the dried powder quickly blown into the built-in fluidized bed at the bottom. The low heat air blown into the built-in fluidized bed carries out the second auxiliary drying of the product, and then the product enters the three-stage vibrating fluidized bed for the third low-temperature auxiliary drying, And cool to the packaging temperature for temporary packaging. The fine powder recovered by the powder catcher can also be secondary agglomerated and granulated through the built-in fluidized bed at the top or bottom of the tower, so as to improve the instant solubility of the product.

Milk Powder Production Line Main Equipment

The production line for producing milk powder involves several key equipment, each of which plays an important role in the production process. The following is a detailed introduction to the main equipment and its functions:

1. Raw material receiving and storage system

•Raw material tank: used to receive and store fresh milk to ensure the freshness and quality of the raw materials.

•Filter: used to remove impurities and foreign matter in milk.

2. Pretreatment system

•Standardization equipment: by adjusting the fat content and protein content of milk to meet production standards.

•Preheater: preheating milk to a certain temperature helps the subsequent concentration and sterilization process.

3. Concentration system

•Evaporator: evaporates the water in the milk through evaporation technology, increases the solid content, and forms concentrated milk. Common evaporators include single-effect evaporator, multi-effect evaporator and membrane evaporator.

4. Sterilization system

•UHT equipment: heats the concentrated milk to a high temperature and performs instant sterilization to ensure the safety of the product.

5. Cooling system

• Cooler: quickly cool the sterilized concentrated milk to a suitable temperature to prevent bacterial growth.

6. Spray drying system

• Spray drying tower: pass the cooled concentrated milk through the spray drying tower to form fine milk powder particles. The spray drying tower is a key equipment for milk powder production and directly affects the quality and output of the product.

• Hot air furnace: provides hot air required for spray drying.

• Cyclone separator: used to separate the spray-dried milk powder particles and air and recover the milk powder.

7. Cooling and screening system

• Cooling device: cool the spray-dried milk powder to room temperature.

• Vibrating screen: used to screen milk powder, remove large particles and impurities, and ensure product quality.

8. Mixing and flavoring system

• Mixer: according to the product type, add vitamins, minerals, flavors, etc. for uniform mixing.

9. Filling and packaging system

• Filling machine: fill the mixed milk powder into canned or bagged containers.

• Sealing machine: seal the filled container to ensure the hygiene and shelf life of the product.

• Packaging machine: Pack the packaged milk powder for easy transportation and sales.

10. Quality control system

• Laboratory equipment: Used to test the quality of raw materials, intermediate products and finished products to ensure the safety and quality of the products. Including microbiological detectors, chemical analyzers, etc.

• Metal detector: Used to detect whether there are metal impurities in milk powder to ensure product safety.

11. Storage and transportation system

• Finished product warehouse: Used to store finished products and ensure that the products are stored in a suitable environment.

• Transport vehicles: Used to transport products to various sales points, select appropriate transportation methods and cold chain systems to ensure that the products are not affected by temperature during transportation.

Raw materials and products of Milk Powder Production Line

1. Raw materials

The raw materials required for the production of milk powder mainly include dairy products and other auxiliary raw materials. The following is a detailed list of raw materials:

• Fresh milk: the main raw material, select fresh and uncontaminated milk, and undergo preliminary processing and inspection to ensure the quality of the raw materials.

• Skim milk: used to produce skim milk powder, and the fat is separated from the milk by a centrifuge.

• Whole milk: used to produce whole milk powder, retaining all the fat components in the milk.

• Water: used to clean equipment and dilute milk, the water quality should be clean and uncontaminated.

• Lactose: used to adjust the sweetness and taste of milk powder.

• Emulsifiers: such as monoglycerides and lecithin, used to improve the solubility and stability of milk powder.

• Stabilizers: such as carrageenan and xanthan gum, used to improve the stability and taste of milk powder.

• Vitamins and minerals: such as vitamin A, D, calcium, and iron, used to enhance the nutritional value of milk powder.

• Flavors: such as vanilla flavor and coconut flavor, used to increase the flavor of milk powder.

• Preservatives: such as potassium sorbate, used to extend the shelf life of milk powder.

• Enzyme preparations: such as lactase, used to break down lactose, suitable for people with lactose intolerance.

2. Products

The milk powder production line can produce many different types of milk powder products. The following are some common product types:

• Whole milk powder: retains all the fat components in milk, has a rich taste, and is suitable for direct brewing or for baking and cooking.

• Skim milk powder: The fat is separated from the milk by a centrifuge, and the fat content is low, suitable for people who need to control their fat intake.

• Low-fat milk powder: The fat content is between whole milk powder and skim milk powder, suitable for people who need to balance their fat intake.

• Infant formula milk powder: designed for infants and young children of different ages, with essential vitamins, minerals and other nutrients added to meet the special nutritional needs of infants and young children.

•Special medical formula milk powder: used for the treatment or auxiliary treatment of specific diseases, such as diabetes, kidney disease, etc., with specific nutrients added.

•Organic milk powder: using organic milk and organic excipients, following the standards of organic agriculture, without chemical pesticides and hormones.

•Fortified milk powder: adding vitamins and minerals, such as vitamin A, D, and calcium, to enhance the nutritional value of milk powder, suitable for nutritional supplementation.

| Form | End product | Production capacity | Core Process |

| Wet+spray drying | Infant formula | 5-30 t/day | Vacuum mixing+triple effect evaporation+MSD drying |

| Dry mixing+packaging | Formulated milk powder | 1-5t/h | Weight loss scale dry mixing+nitrogen filling packaging |

| Wet and dry mixing combined in one | Full fat/skimmed | 10-60 t/day | Concentration+spray+dry mixing rear section |

| high-speed lines | Infant canned powder | 400-600 cans/min | Automatic tank sorting+nitrogen filling+robot packing |

| 25 kg powder bag line | Industrial milk based powder | 120-200 bags/h | Vacuum+nitrogen flushing+automatic palletizing |

The customization process for a milk powder production line involves several key steps to ensure that the final product meets specific requirements and quality standards. Here’s a detailed breakdown of the customization process:

2. Designing the Production Line Layout Once the requirements are gathered, engineers will design a layout for the production line. This layout will include all necessary components such as raw milk receiving tanks, preheating machines, homogenizers, evaporators, spray dryers, cooling systems, and packaging units. The design must optimize space while ensuring efficient workflow and adherence to hygiene standards.

3. Selection of Equipment Based on the designed layout and specific product requirements, appropriate equipment will be selected. This includes:

4. Customization of Equipment Each piece of equipment may require customization based on factors like:

5. Installation and Commissioning After selecting and customizing equipment, installation begins at the client’s facility. This phase includes:

6. Training Staff Once installation is complete, training sessions are conducted for operational staff. This training covers:

7. Quality Control Implementation A robust quality control system is established throughout the production line. This includes:

8. Final Testing and Adjustment Before full-scale production begins, final testing is conducted to ensure everything operates smoothly under real conditions. Adjustments may be made based on performance data collected during these tests.

9. Ongoing Support and Maintenance After commissioning, ongoing support is provided which may include regular maintenance checks, troubleshooting assistance, or further adjustments based on evolving client needs or market demands.