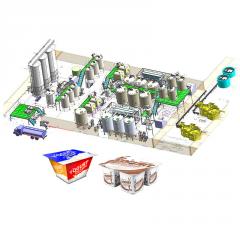

Milk coffee production line

The milk coffee production line is a highly automated and efficient system specifically designed for producing various types of milk coffee products, such as latte, cappuccino, mocha, etc. This production line combines modern technology and strict quality control to ensure that the taste, color, and quality of each batch of products reach their optimal state.

Main components

1.Raw material preparation area:

•

Coffee bean processing: Select high-quality coffee beans, roast and grind them to ensure the rich aroma of coffee.

•

Milk processing: Fresh milk is filtered, homogenized, and pasteurized to ensure hygiene and taste.

2.Mixing and blending area:

•

Automatic ingredient system: Accurately control the ratio of coffee liquid to milk, ensuring consistent taste for each cup of milk coffee.

•

Stirring device: It can mix coffee and milk with high efficiency to form delicate foam.

3.Filling and sealing area:

•

Filling machine: automatically fills the prepared milk coffee into bottled or cup-shaped containers.

•

Sealing machine: adopting advanced sealing technology to ensure the sealing and shelf life of the product.

4.Cooling and packaging area:

•

Cooling system: Quickly cool the filled milk coffee to prevent bacterial growth.

•

Packaging machine: Packaging cooled milk coffee in common forms such as paper boxes, plastic bottles, glass bottles, etc.

5.Quality inspection area:

•

Sensory testing: Through visual, olfactory, gustatory and other sensory testing, ensure that the appearance and taste of the product meet the standards.

•

Physical and chemical testing: Through laboratory analysis, the microbial indicators and nutritional components of the product are tested to ensure safety and health.

6.Storage and Logistics Area:

•

Finished product warehouse: store qualified milk and coffee products, maintain appropriate temperature and humidity.

•

Logistics system: Transport finished products to various sales points to ensure timely delivery.

key technology

•

Automation control system: Through PLC (programmable logic controller) and SCADA (data acquisition and monitoring control system), achieve automation control and monitoring of the entire line.

•

CIP (In situ Cleaning) system: ensures cleanliness and hygiene at all stages of the production line, reducing cross contamination.

•

Energy saving technology: adopting efficient energy management systems to reduce energy consumption and improve production efficiency.

Advantage

•

High efficiency: Automated production lines greatly improve production efficiency and reduce labor costs.

•

High quality: A strict quality control system ensures the stability and consistency of each batch of products.

•

Flexibility: The production line can be quickly adjusted according to market demand to produce different types of milk coffee products.

•

Safety: Advanced detection technology and hygiene management measures ensure the safety and reliability of the product.

Summary

The milk coffee production line integrates modern technology and automation equipment to achieve efficient and high-quality milk coffee production. Whether it is small batch customization or large-scale production, this production line can meet the needs of different customers and provide the market with a rich and diverse range of milk and coffee products.

1. Raw material processing equipment

Coffee bean processing equipment:

•

Coffee bean screening machine: used to remove impurities and defective coffee beans.

•

Coffee bean roaster: By high-temperature roasting, coffee beans produce a unique aroma and flavor.

•

Coffee bean grinder: Grind roasted coffee beans into powder for easy extraction.

Milk processing equipment:

•

Milk filter: removes impurities from milk to ensure the purity of raw materials.

•

Homogenizer: By using high pressure to evenly distribute fat particles in milk, it improves the taste.

•

Pasteurization machine: Low temperature sterilization treatment of milk to ensure hygiene and safety.

2. Mixing and blending equipment

Automatic batching system:

•

Flow meter: Accurately measure the flow rate of coffee and milk to ensure accurate proportion.

•

Automatic valve: controls the flow of liquid to ensure the automation of the batching process.

Mixing device:

•

High speed mixer: It can mix coffee and milk with high efficiency to form delicate foam.

•

Temperature control device: Adjust the temperature of the mixture to ensure optimal taste.

3. Filling and sealing equipment

one

Filling machine:

•

Linear filling machine: suitable for filling bottled or cup-shaped products.

•

Rotary filling machine: suitable for efficient filling in large-scale production.

two

Sealing machine:

•

Capping machine: used for sealing bottled products.

•

Heat sealing machine: used for sealing plastic cups or aluminum foil cups.

•

Ultrasonic sealing machine: suitable for sealing products with high sealing requirements.

4. Cooling and packaging equipment

one

Cooling system:

•

Tunnel cooling machine: rapidly cools the filled milk coffee through air or water cooling.

•

Cooling tower: used for centralized cooling of large production lines.

two

packer:

•

Automatic boxing machine: Automatically pack cooled milk and coffee products into cardboard boxes or trays.

•

Heat shrink film packaging machine: used for packaging multi bottle products.

•

Labeling machine: Attach labels to packaging, providing product information and brand identification.

5. Quality inspection equipment

one

Sensory detection equipment:

•

Visual inspection system: detects the appearance of the product through a camera to ensure no defects.

•

Olfactory detection system: detects the odor of the product through sensors to ensure that there is no odor.

two

Physical and chemical testing equipment:

•

Microbial detector: detects the microbial content in products to ensure food safety.

•

Nutrient analyzer: detects the nutritional content of the product to ensure compliance with standards.

6. Automation control system

one

PLC (Programmable Logic Controller): Used to control various parts of the production line and achieve automated operations.

two

SCADA (Supervisory Control and Data Acquisition System): Real time monitoring of the status of the production line, data collection, fault diagnosis, and optimization.

7. CIP (In Situ Cleaning) system

•

Automatic cleaning station: Regularly clean and disinfect various parts of the production line to ensure hygiene.

Summary

The main equipment of the milk coffee production line covers the entire process from raw material processing to final packaging, ensuring production efficiency and product quality through highly automated and intelligent equipment. These devices not only improve production efficiency, but also ensure product safety and consistency.

Milk Coffee Production Line Ingredients and Products

1. Main raw materials

one

coffee bean:

•

Source: High quality coffee beans are usually chosen because they have a more delicate taste and a richer aroma.

•

Processing: Coffee beans undergo screening, roasting, grinding, and other processes to produce coffee powder or concentrated coffee liquid.

•

Quality requirements: Coffee beans should be free from mold and insect infestation, and the roasted coffee beans should have a uniform color and no burnt taste.

two

Milk:

•

Source: Fresh whole milk is selected to ensure a rich milk aroma and smooth taste.

•

Processing: Milk needs to be filtered, homogenized, and pasteurized to ensure hygiene and taste.

•

Quality requirements: Milk should be odorless, free of impurities, and meet national standards for protein and fat content.

three

Water:

•

Source: Use purified or filtered water to ensure clean and impurity free water quality.

•

Treatment: Water needs to undergo softening, filtration, and other treatments to remove minerals and impurities from the water.

•

Quality requirements: The pH value, hardness, and other indicators of water should meet production requirements.

four

Sugar and sweeteners (optional):

•

Source: Natural sweeteners such as white sugar, sucrose, honey, or artificial sweeteners such as aspartame.

•

Processing: Add according to the formula requirements in proportion.

•

Quality requirements: Sweetener should be free of lumps, odors, and meet food safety standards.

five

Other additives (optional):

•

Stabilizers: such as carrageenan, xanthan gum, etc., used to increase the stability of the product.

•

Emulsifier: such as glycerol monostearate, used to improve the taste and appearance of products.

•

Quality requirements: All additives should comply with food safety standards, and the dosage should be strictly controlled.

2. Main products

one

Latte:

•

Ingredients: espresso, steamed milk, milk foam.

•

Features: The ratio of coffee to milk is about 1:3, with a thin layer of milk foam at the top, providing a rich and smooth taste.

two

Cappuccino:

•

Ingredients: espresso, steamed milk, milk foam.

•

Features: The ratio of coffee to milk is about 1:1, with thick milk foam at the top, and a rich and dense taste.

three

Mocha:

•

Ingredients: espresso, steamed milk, chocolate sauce, milk foam.

•

Features: Adding chocolate sauce on top of latte for a richer and sweeter taste.

four

Americano coffee:

•

Ingredients: espresso, hot water.

•

Features: The ratio of coffee to water is about 1:2, with a light taste, suitable for consumers who like the original flavor of coffee.

five

Iced Latte:

•

Ingredients: espresso, iced milk, ice cubes.

•

Features: Suitable for summer consumption, with a cool and smooth taste.

six

Iced Mocha:

•

Ingredients: espresso, iced milk, chocolate sauce, ice cubes.

•

Features: Adding chocolate sauce on top of iced latte for a refreshing and sweet taste.

3. Production process flow

one

Raw material preparation:

•

Screening, roasting, and grinding of coffee beans.

•

Filtering, homogenization, and pasteurization of milk.

•

Softening and filtering of water.

two

Mixing and blending:

•

Mix coffee and milk in proportion, add sugar and other additives.

•

By using a high-speed mixer, the mixed liquid is fully blended to form delicate milk foam.

three

Filling and sealing:

•

Automatically fill the prepared milk coffee into bottled or cup containers.

•

Using different sealing machines for sealing to ensure the sealing and shelf life of the product.

four

Cooling and packaging:

•

Quickly cool the filled milk coffee to prevent bacterial growth.

•

The cooled milk coffee is packaged in common forms such as paper boxes, plastic bottles, glass bottles, etc.

five

Quality inspection:

•

Ensure that the appearance and taste of the product meet the standards through sensory inspection such as visual, olfactory, and gustatory senses.

•

Through laboratory analysis, the microbial indicators and nutritional components of the product are tested to ensure safety and health.

six

Warehousing and Logistics:

•

Store qualified milk coffee products and maintain appropriate temperature and humidity.

•

Transport finished products to various sales points to ensure timely delivery.

Summary

The raw materials and products of the milk coffee production line cover a wide range from high-quality coffee beans and fresh milk to various types of milk coffee products. Through strict raw material processing and production techniques, we ensure that the taste, color, and quality of each batch of products reach their optimal state.

Milk Coffee Production Line Customization Process

Customizing a milk coffee production line requires consideration of multiple aspects, including market demand, production technology, equipment selection, quality control, etc. Here is a detailed customization process:

1. Requirement analysis

•

Market research: Understand the demand for milk coffee in the target market, including consumer preferences, competitor situation, price range, etc.

•

Product positioning: Determine the product type (such as latte, cappuccino, mocha, etc.), as well as the flavor and packaging form of the product.

•

Capacity planning: Determine the production capacity of the production line based on market demand, including daily output, shift scheduling, etc.

2. Process design

•

Raw material processing:

•

Coffee bean processing: screening, roasting, grinding.

•

Milk processing: filtration, homogenization, pasteurization.

•

Water treatment: softening, filtering.

•

Mixing and blending:

•

Ingredient system: Accurately measure raw materials such as coffee liquid, milk, sugar, etc.

•

Blender: Ensure that the mixture is uniform and delicate.

•

Filling and sealing:

•

Filling machine: Choose a suitable filling machine, such as linear, rotary, etc.

•

Sealing machine: Choose the appropriate sealing method, such as screw cap, heat sealing, etc.

•

Cooling and packaging:

•

Cooling equipment: Ensure rapid cooling of the product to prevent bacterial growth.

•

Packaging equipment: Choose appropriate packaging forms, such as paper boxes, plastic bottles, glass bottles, etc.

•

Quality inspection:

•

Sensory detection: vision, smell, taste, etc.

•

Laboratory testing: Microbial indicators, nutritional components, etc.

3. Equipment selection

•

Coffee bean processing equipment:

•

Screening machine: an automatic screening machine to ensure that coffee beans are free of impurities.

•

Baking machine: continuous or batch baking machine, depending on production capacity.

•

Grinding machine: Ultra fine grinding machine to ensure the coffee powder is delicate.

•

Milk processing equipment:

•

Filter: Multi stage filter to ensure that milk is free of impurities.

•

Homogenizer: High pressure homogenizer to ensure smooth taste of milk.

•

Pasteurization machine: Dual temperature pasteurization machine to ensure milk hygiene.

•

Mixing and blending equipment:

•

Ingredient system: precision flowmeter, automatic valve.

•

Blender: Multi stage blender to ensure even mixing of liquids.

•

Filling and sealing equipment:

•

Filling machine: linear filling machine, rotary filling machine.

•

Sealing machine: rotary sealing machine, heat sealing machine.

•

Cooling and packaging equipment:

•

Cooling equipment: tunnel cooling machine, cold water cooling tower.

•

Packaging equipment: automatic packing machine, heat shrink film packaging machine.

4. Layout design

•

Production workshop layout:

•

Raw material area: stores coffee beans, milk and other raw materials.

•

Processing area: coffee bean processing, milk processing.

•

Mixing area: ingredients, mixing.

•

Filling area: Filling and sealing.

•

Cooling zone: cooling equipment.

•

Packaging area: Packaging equipment.

•

Quality inspection area: Quality testing equipment.

•

Logistics channel: Ensure smooth flow of raw materials and finished products to avoid cross contamination.

5. Quality control

•

Raw material inspection: Ensure that the raw materials meet the quality standards.

•

Production process monitoring: Real time monitoring of production parameters such as temperature, pressure, flow rate, etc.

•

Finished product inspection: Conduct sensory and laboratory testing to ensure product quality.

•

Traceability system: Establish a product quality traceability system to ensure the traceability of each batch of products.

6. Training and Operation

•

Employee training: Provide training to operators on equipment operation, maintenance, cleaning, and other aspects.

•

Operating procedures: Develop detailed operating procedures and safety standards to ensure smooth production.

7. Trial operation and debugging

•

Trial operation: Conduct a trial operation before formal production to check the operation of the equipment.

•

Debugging: Make necessary adjustments and optimizations based on the results of the trial run.

8. Formally put into operation

•

Production plan: Develop detailed production plans to ensure orderly production.

•

Continuous improvement: Regularly evaluate the operation of the production line and carry out continuous improvement.

Summary

Customizing a milk coffee production line is a complex process that requires comprehensive consideration of market demand, production technology, equipment selection, quality control, and other aspects. Through scientific and rational planning and implementation, the production line can operate efficiently and stably, producing high-quality milk and coffee products.

Main components

1.Raw material preparation area:

•

Coffee bean processing: Select high-quality coffee beans, roast and grind them to ensure the rich aroma of coffee.

•

Milk processing: Fresh milk is filtered, homogenized, and pasteurized to ensure hygiene and taste.

2.Mixing and blending area:

•

Automatic ingredient system: Accurately control the ratio of coffee liquid to milk, ensuring consistent taste for each cup of milk coffee.

•

Stirring device: It can mix coffee and milk with high efficiency to form delicate foam.

3.Filling and sealing area:

•

Filling machine: automatically fills the prepared milk coffee into bottled or cup-shaped containers.

•

Sealing machine: adopting advanced sealing technology to ensure the sealing and shelf life of the product.

4.Cooling and packaging area:

•

Cooling system: Quickly cool the filled milk coffee to prevent bacterial growth.

•

Packaging machine: Packaging cooled milk coffee in common forms such as paper boxes, plastic bottles, glass bottles, etc.

5.Quality inspection area:

•

Sensory testing: Through visual, olfactory, gustatory and other sensory testing, ensure that the appearance and taste of the product meet the standards.

•

Physical and chemical testing: Through laboratory analysis, the microbial indicators and nutritional components of the product are tested to ensure safety and health.

6.Storage and Logistics Area:

•

Finished product warehouse: store qualified milk and coffee products, maintain appropriate temperature and humidity.

•

Logistics system: Transport finished products to various sales points to ensure timely delivery.

key technology

•

Automation control system: Through PLC (programmable logic controller) and SCADA (data acquisition and monitoring control system), achieve automation control and monitoring of the entire line.

•

CIP (In situ Cleaning) system: ensures cleanliness and hygiene at all stages of the production line, reducing cross contamination.

•

Energy saving technology: adopting efficient energy management systems to reduce energy consumption and improve production efficiency.

Advantage

•

High efficiency: Automated production lines greatly improve production efficiency and reduce labor costs.

•

High quality: A strict quality control system ensures the stability and consistency of each batch of products.

•

Flexibility: The production line can be quickly adjusted according to market demand to produce different types of milk coffee products.

•

Safety: Advanced detection technology and hygiene management measures ensure the safety and reliability of the product.

Summary

The milk coffee production line integrates modern technology and automation equipment to achieve efficient and high-quality milk coffee production. Whether it is small batch customization or large-scale production, this production line can meet the needs of different customers and provide the market with a rich and diverse range of milk and coffee products.

1. Raw material processing equipment

Coffee bean processing equipment:

•

Coffee bean screening machine: used to remove impurities and defective coffee beans.

•

Coffee bean roaster: By high-temperature roasting, coffee beans produce a unique aroma and flavor.

•

Coffee bean grinder: Grind roasted coffee beans into powder for easy extraction.

Milk processing equipment:

•

Milk filter: removes impurities from milk to ensure the purity of raw materials.

•

Homogenizer: By using high pressure to evenly distribute fat particles in milk, it improves the taste.

•

Pasteurization machine: Low temperature sterilization treatment of milk to ensure hygiene and safety.

2. Mixing and blending equipment

Automatic batching system:

•

Flow meter: Accurately measure the flow rate of coffee and milk to ensure accurate proportion.

•

Automatic valve: controls the flow of liquid to ensure the automation of the batching process.

Mixing device:

•

High speed mixer: It can mix coffee and milk with high efficiency to form delicate foam.

•

Temperature control device: Adjust the temperature of the mixture to ensure optimal taste.

3. Filling and sealing equipment

one

Filling machine:

•

Linear filling machine: suitable for filling bottled or cup-shaped products.

•

Rotary filling machine: suitable for efficient filling in large-scale production.

two

Sealing machine:

•

Capping machine: used for sealing bottled products.

•

Heat sealing machine: used for sealing plastic cups or aluminum foil cups.

•

Ultrasonic sealing machine: suitable for sealing products with high sealing requirements.

4. Cooling and packaging equipment

one

Cooling system:

•

Tunnel cooling machine: rapidly cools the filled milk coffee through air or water cooling.

•

Cooling tower: used for centralized cooling of large production lines.

two

packer:

•

Automatic boxing machine: Automatically pack cooled milk and coffee products into cardboard boxes or trays.

•

Heat shrink film packaging machine: used for packaging multi bottle products.

•

Labeling machine: Attach labels to packaging, providing product information and brand identification.

5. Quality inspection equipment

one

Sensory detection equipment:

•

Visual inspection system: detects the appearance of the product through a camera to ensure no defects.

•

Olfactory detection system: detects the odor of the product through sensors to ensure that there is no odor.

two

Physical and chemical testing equipment:

•

Microbial detector: detects the microbial content in products to ensure food safety.

•

Nutrient analyzer: detects the nutritional content of the product to ensure compliance with standards.

6. Automation control system

one

PLC (Programmable Logic Controller): Used to control various parts of the production line and achieve automated operations.

two

SCADA (Supervisory Control and Data Acquisition System): Real time monitoring of the status of the production line, data collection, fault diagnosis, and optimization.

7. CIP (In Situ Cleaning) system

•

Automatic cleaning station: Regularly clean and disinfect various parts of the production line to ensure hygiene.

Summary

The main equipment of the milk coffee production line covers the entire process from raw material processing to final packaging, ensuring production efficiency and product quality through highly automated and intelligent equipment. These devices not only improve production efficiency, but also ensure product safety and consistency.

Milk Coffee Production Line Ingredients and Products

1. Main raw materials

one

coffee bean:

•

Source: High quality coffee beans are usually chosen because they have a more delicate taste and a richer aroma.

•

Processing: Coffee beans undergo screening, roasting, grinding, and other processes to produce coffee powder or concentrated coffee liquid.

•

Quality requirements: Coffee beans should be free from mold and insect infestation, and the roasted coffee beans should have a uniform color and no burnt taste.

two

Milk:

•

Source: Fresh whole milk is selected to ensure a rich milk aroma and smooth taste.

•

Processing: Milk needs to be filtered, homogenized, and pasteurized to ensure hygiene and taste.

•

Quality requirements: Milk should be odorless, free of impurities, and meet national standards for protein and fat content.

three

Water:

•

Source: Use purified or filtered water to ensure clean and impurity free water quality.

•

Treatment: Water needs to undergo softening, filtration, and other treatments to remove minerals and impurities from the water.

•

Quality requirements: The pH value, hardness, and other indicators of water should meet production requirements.

four

Sugar and sweeteners (optional):

•

Source: Natural sweeteners such as white sugar, sucrose, honey, or artificial sweeteners such as aspartame.

•

Processing: Add according to the formula requirements in proportion.

•

Quality requirements: Sweetener should be free of lumps, odors, and meet food safety standards.

five

Other additives (optional):

•

Stabilizers: such as carrageenan, xanthan gum, etc., used to increase the stability of the product.

•

Emulsifier: such as glycerol monostearate, used to improve the taste and appearance of products.

•

Quality requirements: All additives should comply with food safety standards, and the dosage should be strictly controlled.

2. Main products

one

Latte:

•

Ingredients: espresso, steamed milk, milk foam.

•

Features: The ratio of coffee to milk is about 1:3, with a thin layer of milk foam at the top, providing a rich and smooth taste.

two

Cappuccino:

•

Ingredients: espresso, steamed milk, milk foam.

•

Features: The ratio of coffee to milk is about 1:1, with thick milk foam at the top, and a rich and dense taste.

three

Mocha:

•

Ingredients: espresso, steamed milk, chocolate sauce, milk foam.

•

Features: Adding chocolate sauce on top of latte for a richer and sweeter taste.

four

Americano coffee:

•

Ingredients: espresso, hot water.

•

Features: The ratio of coffee to water is about 1:2, with a light taste, suitable for consumers who like the original flavor of coffee.

five

Iced Latte:

•

Ingredients: espresso, iced milk, ice cubes.

•

Features: Suitable for summer consumption, with a cool and smooth taste.

six

Iced Mocha:

•

Ingredients: espresso, iced milk, chocolate sauce, ice cubes.

•

Features: Adding chocolate sauce on top of iced latte for a refreshing and sweet taste.

3. Production process flow

one

Raw material preparation:

•

Screening, roasting, and grinding of coffee beans.

•

Filtering, homogenization, and pasteurization of milk.

•

Softening and filtering of water.

two

Mixing and blending:

•

Mix coffee and milk in proportion, add sugar and other additives.

•

By using a high-speed mixer, the mixed liquid is fully blended to form delicate milk foam.

three

Filling and sealing:

•

Automatically fill the prepared milk coffee into bottled or cup containers.

•

Using different sealing machines for sealing to ensure the sealing and shelf life of the product.

four

Cooling and packaging:

•

Quickly cool the filled milk coffee to prevent bacterial growth.

•

The cooled milk coffee is packaged in common forms such as paper boxes, plastic bottles, glass bottles, etc.

five

Quality inspection:

•

Ensure that the appearance and taste of the product meet the standards through sensory inspection such as visual, olfactory, and gustatory senses.

•

Through laboratory analysis, the microbial indicators and nutritional components of the product are tested to ensure safety and health.

six

Warehousing and Logistics:

•

Store qualified milk coffee products and maintain appropriate temperature and humidity.

•

Transport finished products to various sales points to ensure timely delivery.

Summary

The raw materials and products of the milk coffee production line cover a wide range from high-quality coffee beans and fresh milk to various types of milk coffee products. Through strict raw material processing and production techniques, we ensure that the taste, color, and quality of each batch of products reach their optimal state.

Milk Coffee Production Line Customization Process

Customizing a milk coffee production line requires consideration of multiple aspects, including market demand, production technology, equipment selection, quality control, etc. Here is a detailed customization process:

1. Requirement analysis

•

Market research: Understand the demand for milk coffee in the target market, including consumer preferences, competitor situation, price range, etc.

•

Product positioning: Determine the product type (such as latte, cappuccino, mocha, etc.), as well as the flavor and packaging form of the product.

•

Capacity planning: Determine the production capacity of the production line based on market demand, including daily output, shift scheduling, etc.

2. Process design

•

Raw material processing:

•

Coffee bean processing: screening, roasting, grinding.

•

Milk processing: filtration, homogenization, pasteurization.

•

Water treatment: softening, filtering.

•

Mixing and blending:

•

Ingredient system: Accurately measure raw materials such as coffee liquid, milk, sugar, etc.

•

Blender: Ensure that the mixture is uniform and delicate.

•

Filling and sealing:

•

Filling machine: Choose a suitable filling machine, such as linear, rotary, etc.

•

Sealing machine: Choose the appropriate sealing method, such as screw cap, heat sealing, etc.

•

Cooling and packaging:

•

Cooling equipment: Ensure rapid cooling of the product to prevent bacterial growth.

•

Packaging equipment: Choose appropriate packaging forms, such as paper boxes, plastic bottles, glass bottles, etc.

•

Quality inspection:

•

Sensory detection: vision, smell, taste, etc.

•

Laboratory testing: Microbial indicators, nutritional components, etc.

3. Equipment selection

•

Coffee bean processing equipment:

•

Screening machine: an automatic screening machine to ensure that coffee beans are free of impurities.

•

Baking machine: continuous or batch baking machine, depending on production capacity.

•

Grinding machine: Ultra fine grinding machine to ensure the coffee powder is delicate.

•

Milk processing equipment:

•

Filter: Multi stage filter to ensure that milk is free of impurities.

•

Homogenizer: High pressure homogenizer to ensure smooth taste of milk.

•

Pasteurization machine: Dual temperature pasteurization machine to ensure milk hygiene.

•

Mixing and blending equipment:

•

Ingredient system: precision flowmeter, automatic valve.

•

Blender: Multi stage blender to ensure even mixing of liquids.

•

Filling and sealing equipment:

•

Filling machine: linear filling machine, rotary filling machine.

•

Sealing machine: rotary sealing machine, heat sealing machine.

•

Cooling and packaging equipment:

•

Cooling equipment: tunnel cooling machine, cold water cooling tower.

•

Packaging equipment: automatic packing machine, heat shrink film packaging machine.

4. Layout design

•

Production workshop layout:

•

Raw material area: stores coffee beans, milk and other raw materials.

•

Processing area: coffee bean processing, milk processing.

•

Mixing area: ingredients, mixing.

•

Filling area: Filling and sealing.

•

Cooling zone: cooling equipment.

•

Packaging area: Packaging equipment.

•

Quality inspection area: Quality testing equipment.

•

Logistics channel: Ensure smooth flow of raw materials and finished products to avoid cross contamination.

5. Quality control

•

Raw material inspection: Ensure that the raw materials meet the quality standards.

•

Production process monitoring: Real time monitoring of production parameters such as temperature, pressure, flow rate, etc.

•

Finished product inspection: Conduct sensory and laboratory testing to ensure product quality.

•

Traceability system: Establish a product quality traceability system to ensure the traceability of each batch of products.

6. Training and Operation

•

Employee training: Provide training to operators on equipment operation, maintenance, cleaning, and other aspects.

•

Operating procedures: Develop detailed operating procedures and safety standards to ensure smooth production.

7. Trial operation and debugging

•

Trial operation: Conduct a trial operation before formal production to check the operation of the equipment.

•

Debugging: Make necessary adjustments and optimizations based on the results of the trial run.

8. Formally put into operation

•

Production plan: Develop detailed production plans to ensure orderly production.

•

Continuous improvement: Regularly evaluate the operation of the production line and carry out continuous improvement.

Summary

Customizing a milk coffee production line is a complex process that requires comprehensive consideration of market demand, production technology, equipment selection, quality control, and other aspects. Through scientific and rational planning and implementation, the production line can operate efficiently and stably, producing high-quality milk and coffee products.

Feedback form contact with us