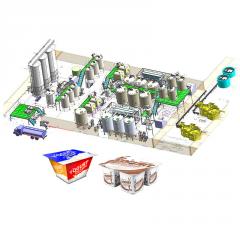

Lactic acid bacteria beverage production line

Brief introduction of lactic acid bacteria beverage production lineLactic acid bacteria beverage is a healthy drink rich in active lactic acid bacteria, which has many functions such as promoting intestinal health and enhancing immunity. In order to produce high-quality lactic acid bacteria beverages, an efficient, hygienic and food safety-compliant production line is required. The following are the key components and process flow of the lactic acid bacteria beverage production line:

I. Production line composition

1. Raw material processing area

• Receiving and storage: used to receive and store main raw materials such as milk and juice.

• Pretreatment equipment: including filters, centrifuges, etc. to ensure the purity of raw materials.

2. Fermentation area

• Fermentation tank: equipped with temperature control system and stirring device to provide a suitable growth environment for lactic acid bacteria and carry out the fermentation process.

• Inoculation equipment: accurately control the amount of lactic acid bacteria added to ensure stable fermentation effect.

3. Preparation area

• Preparation tank: add sugar, sweeteners, vitamins and other auxiliary materials according to the formula to adjust the taste and nutritional content.

• Homogenizer: make the mixed liquid uniform and prevent stratification.

4. Sterilization area

•Pasteurization equipment: Use gentle heating to sterilize the product, which kills harmful microorganisms and retains the activity of lactic acid bacteria.

•Cooling equipment: Rapidly cool to a suitable temperature to maintain product quality.

5. Filling area

•Aseptic filling machine: Complete filling in a sterile environment to avoid secondary contamination.

•Sealing machine: Ensure that the package is well sealed and extend the shelf life.

6. Packaging area

•Automatic packaging line: Package the finished product according to different specifications, such as bottles, boxes or bags.

•Labeling machine: Print information such as production date and shelf life, and affix labels.

7. Quality testing area

•Physical and chemical analysis instruments: Detect indicators such as pH value, sugar content, protein content, etc.

•Microbial testing equipment: Ensure that the product does not contain pathogenic bacteria and other harmful microorganisms.

II. Production process

1. Raw material preparation

•Select high-quality raw materials (milk, juice, etc.) and send them to the fermentation tank after pretreatment.

2. Fermentation process

•Inoculate the lactic acid bacteria into the raw materials and ferment under specific temperature and time conditions.

•Strictly monitor various parameters during the fermentation process, such as temperature, acidity, and viable count.

3. Blending and homogenization

•Add auxiliary materials according to the product formula and use a homogenizer to make the mixed liquid uniform and stable.

4. Sterilization and cooling

•Quickly cool after pasteurization to maintain the activity of lactic acid bacteria and the safety of the product.

5. Filling and packaging

•Filling and sealing in a sterile environment, followed by outer packaging.

6. Quality inspection

•Perform comprehensive quality inspection on each batch of products to ensure compliance with food safety standards.

III. Key technologies and equipment

1. Automated control system

•The entire production line uses PLC or DCS system for automated control to realize functions such as data acquisition, process monitoring, and fault alarm.

2. CIP cleaning system

•The Clean-In-Place system is used to clean pipes, containers and other components to ensure the hygiene of the production environment.

3. Aseptic technology

• The filling area uses aseptic air supply system and ultraviolet disinfection lamps to ensure that the product is not contaminated.

4. Energy-saving and environmental protection measures

• High-efficiency refrigeration units and heat recovery devices are used to reduce energy consumption; sewage treatment facilities are also configured to reduce environmental pollution.

I. Production line composition

1. Raw material processing area

• Receiving and storage: used to receive and store main raw materials such as milk and juice.

• Pretreatment equipment: including filters, centrifuges, etc. to ensure the purity of raw materials.

2. Fermentation area

• Fermentation tank: equipped with temperature control system and stirring device to provide a suitable growth environment for lactic acid bacteria and carry out the fermentation process.

• Inoculation equipment: accurately control the amount of lactic acid bacteria added to ensure stable fermentation effect.

3. Preparation area

• Preparation tank: add sugar, sweeteners, vitamins and other auxiliary materials according to the formula to adjust the taste and nutritional content.

• Homogenizer: make the mixed liquid uniform and prevent stratification.

4. Sterilization area

•Pasteurization equipment: Use gentle heating to sterilize the product, which kills harmful microorganisms and retains the activity of lactic acid bacteria.

•Cooling equipment: Rapidly cool to a suitable temperature to maintain product quality.

5. Filling area

•Aseptic filling machine: Complete filling in a sterile environment to avoid secondary contamination.

•Sealing machine: Ensure that the package is well sealed and extend the shelf life.

6. Packaging area

•Automatic packaging line: Package the finished product according to different specifications, such as bottles, boxes or bags.

•Labeling machine: Print information such as production date and shelf life, and affix labels.

7. Quality testing area

•Physical and chemical analysis instruments: Detect indicators such as pH value, sugar content, protein content, etc.

•Microbial testing equipment: Ensure that the product does not contain pathogenic bacteria and other harmful microorganisms.

II. Production process

1. Raw material preparation

•Select high-quality raw materials (milk, juice, etc.) and send them to the fermentation tank after pretreatment.

2. Fermentation process

•Inoculate the lactic acid bacteria into the raw materials and ferment under specific temperature and time conditions.

•Strictly monitor various parameters during the fermentation process, such as temperature, acidity, and viable count.

3. Blending and homogenization

•Add auxiliary materials according to the product formula and use a homogenizer to make the mixed liquid uniform and stable.

4. Sterilization and cooling

•Quickly cool after pasteurization to maintain the activity of lactic acid bacteria and the safety of the product.

5. Filling and packaging

•Filling and sealing in a sterile environment, followed by outer packaging.

6. Quality inspection

•Perform comprehensive quality inspection on each batch of products to ensure compliance with food safety standards.

III. Key technologies and equipment

1. Automated control system

•The entire production line uses PLC or DCS system for automated control to realize functions such as data acquisition, process monitoring, and fault alarm.

2. CIP cleaning system

•The Clean-In-Place system is used to clean pipes, containers and other components to ensure the hygiene of the production environment.

3. Aseptic technology

• The filling area uses aseptic air supply system and ultraviolet disinfection lamps to ensure that the product is not contaminated.

4. Energy-saving and environmental protection measures

• High-efficiency refrigeration units and heat recovery devices are used to reduce energy consumption; sewage treatment facilities are also configured to reduce environmental pollution.

Feedback form contact with us