A roller juicer is a device used to extract fruit juice, which uses a roller shaft to squeeze fruits or vegetables, thereby separating the juice from them. Unlike traditional juicers, roller juicers crush fruits or vegetables through the rotational motion of the roller shaft, and then separate the juice from the solids through high-speed rotating drums.

The roller juicer has the following characteristics:

1. High efficiency: The roller juicer adopts the squeezing principle of the roller shaft, which can fully utilize the juice of fruits or vegetables and improve the extraction rate of the juice. Compared to traditional juicers, roller juicers have higher efficiency and can save time and labor costs.

2. Low calorie: The roller juicer reduces the generation of frictional heat during the juice extraction process, lowers the temperature of the juice, and thus retains more nutrients and taste. Compared to some high-speed centrifugal juicers, roller juicers generate less heat and can produce fresher and healthier juice.

3. Widely applicable: The roller juicer is suitable for extracting various fruits and vegetables, whether it is citrus fruits, melon fruits, or hard vegetables, and can extract juice through the roller juicer. It has good adaptability and universality, and can meet the needs of different users.

4. Low noise: The noise generated during the operation of the roller juicer is relatively low, providing users with a more comfortable user experience. This enables roller juicers to be widely used in both households and commercial settings without causing interference to the surrounding environment and people's normal lives.

In summary, the roller juicer is an efficient, low calorie, widely applicable, and low noise equipment suitable for the extraction of various fruits and vegetables. It is the ideal choice for making fresh and healthy juice.

Main application:

This equipment is mainly used for crushing and juice extraction of oranges, citrus and other fruits & vegetables. It is designed according to the hygienic requirements of the food industry, simple to operate, convenient to use and maintain, and can be used on the automatic processing line.

Main features :

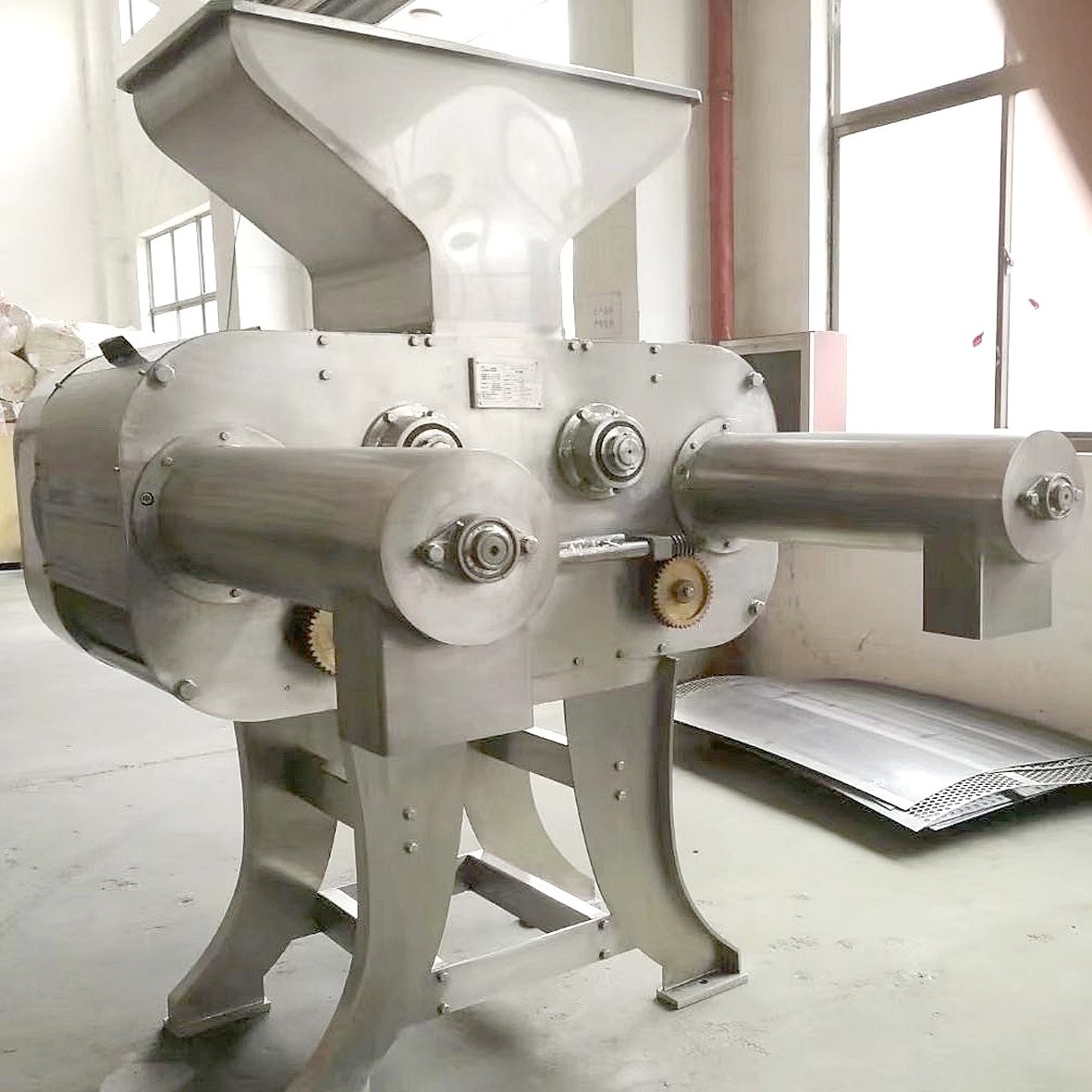

Machine support designed with whole frame welding structure, good rigidity and small vibration.

Compact structure, small floor space, reliable operation; Optimized design of each component makes cleaning and replacement more convenient.All stainless steel manufacturing, comply with food hygiene standards.Installed in the processing line, automatic production with low labor intensity.

The press roller has protruding needles on the surface to grab the fruit.

The press roller and the sieve are half crescent shape, and the gap gradually decreases from large to small, which can squeeze the pulp well.

Automatic separation of fruit pulp and peel, high production capacity, the gap between extraction roll and filtration net will be adjusted according to different products.meet the requirements of production.

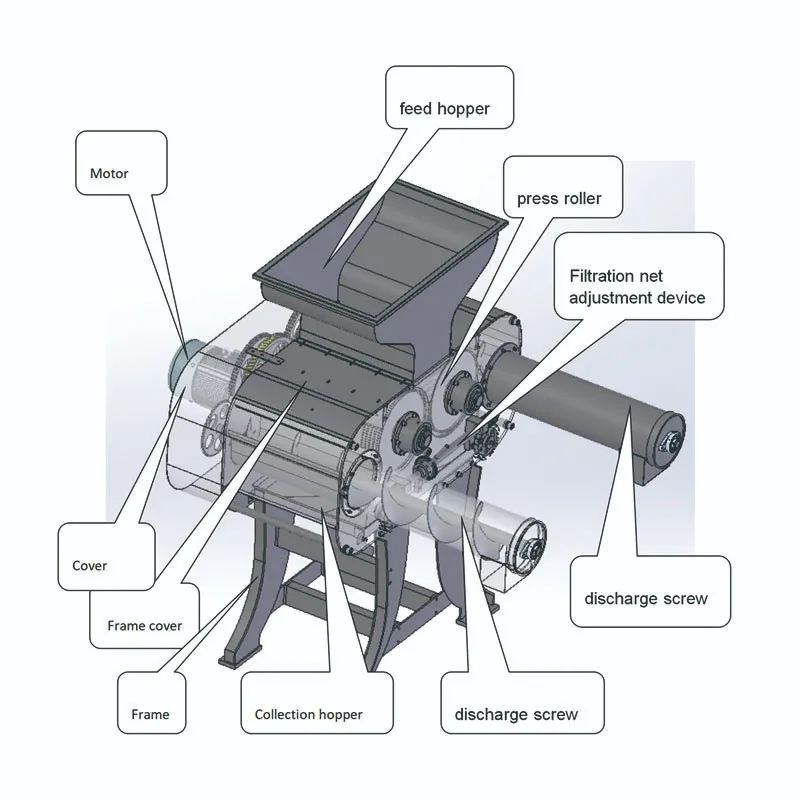

Components of the equipment :

Fruit ready to be extracted come from the procedure into the extractor feed hopper, from the feed hopper to the middle of two squeezing roller, needle shaped squeezing roller surface will be holding the fruit by extruding, in the process of extrusion, will contact with cutting knife, the cutting knife cut fruit, with the press roll rotation, the fruits keep turning, filtration net and pulp further squeeze, thus the pulp and peel to further separation.

Size Chart of This Design

|

Model

|

Capacity

|

Motor power:

|

Mechanical size

|

Extracting heads

|

|

ZZJ-5

|

5TPH

|

5.5KW,960r/min

|

1700*1670*1600mm

|

7 pcs/ drum

|

|

ZZJ-10

|

10TPH

|

9KW,960r/min

|

2200*2250*2800mm

|

7 pcs/ drum

|