Fruit Destoner is a device used to remove stones or seeds from fruits. It is widely used in the fruit processing industry, especially in the production of jam, jam, preserved fruits, and other fruit products. The corer can automatically separate the kernels or seeds from fruits, improving production efficiency and reducing manual operations.

The fruit corer mainly consists of the following parts:

Feeding device: A device used to feed fruits into a corer. Usually, conveyor belts or vibrating devices are used to transport fruits from the feeding port to the de nucleating area.

Denucleation device: Different nucleation techniques are used, such as pressing, squeezing, or shearing, to separate the nuclei or seeds in fruits. These devices typically consist of mechanical systems with specially designed rollers or blades.

Separation device: used to separate fruits that have already been removed from their kernels or seeds. Usually, separated by wind or gravity, the cored fruit is separated from the waste.

Discharge device: Sends the fruit after being removed from the pit to the pit machine and proceeds with the next step of processing. Fruits can be discharged from the corer through conveyor belts or other material transfer methods.

The working principle of a fruit pit removal machine is to send the fruit into the pit removal machine, use specific pit removal technology to separate the pit or seed in the fruit, and then separate the pit removed fruit from the pit or seed. This can improve the efficiency and quality of fruit processing, and reduce manual labor.

Fruit corers play an important role in the fruit processing industry. It can not only improve production efficiency, but also ensure the quality and taste of the product. At the same time, it can also reduce production costs and human resource investment. Therefore, many fruit processing enterprises use fruit corers to improve production efficiency and product quality.

Description of fruit destoner:

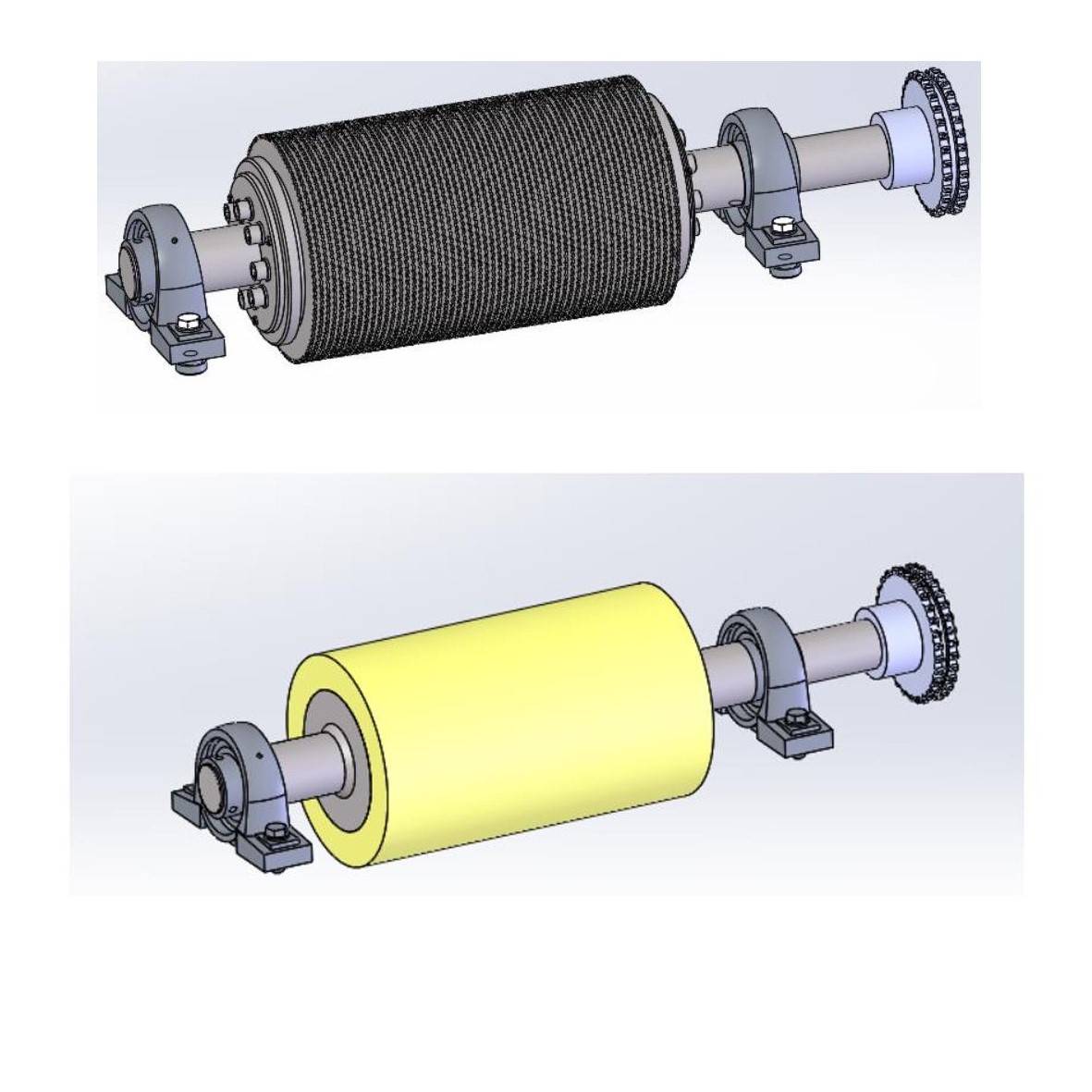

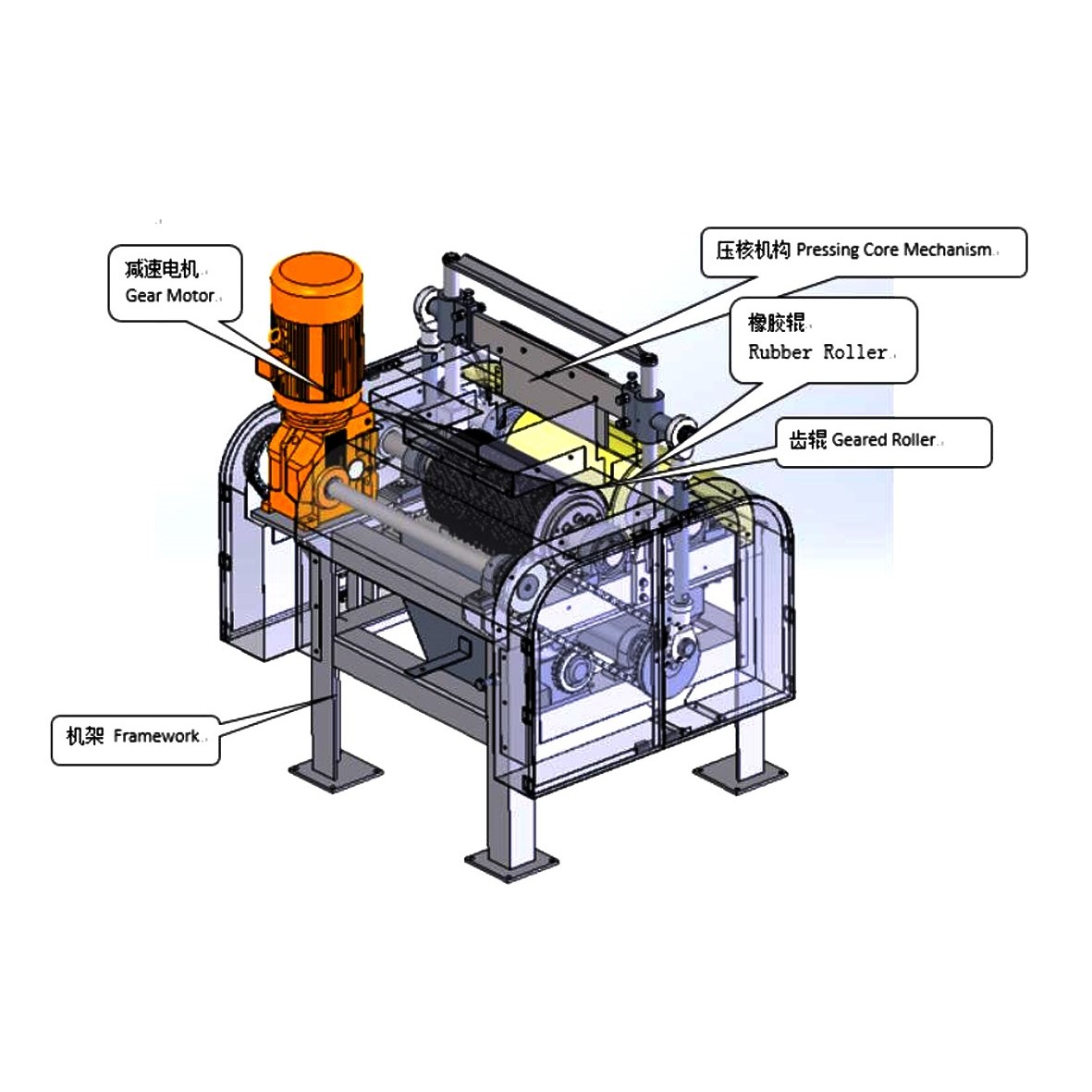

This machine is used to remove the seeds from the hard seed fruits in normal temperature, which is one of the key equipments in the stone fruits juice processing lines; such as the peach, apricot etc.This type destoner removes the hard stone from the fruits by two rollers (one has teeth on the surface, and the other is made of rubber ) which are kept with a certain gap in between; The gap between the two rollers is designed according the feature and dimension of different fruits;

The fruits fall down to the rollers from the former procedure and then are pressed to the gap by a plate which moves up and down; the two rollers rolls in opposite direction and most of the flesh is pressed to the gap of the teeth on the roller meanwhile the stones(seed of the fruit) are pressed on the stretchy roller; the flesh between the teeth on the roller will be then scratched out by a brush. The stone still with some flesh on it will be backward washed by the stoner washer.

by this way, the fruit stone is removed and the flesh of the fruit will be remained in state of pieces.

Features:

1. Can separate the fruit flesh and the stone effectively;2. Higher effectively and easy operation;

3. The gap between the rollers can be regulated to get a best process efficient;

4. The rollers and the scraper can be replaced considering the status of the machine, and it is easy to do the replacement;

5. The supporter adopts high quality SUS304 stainless steel as material to have a good integral structure;

6. The whole machine is made to be close construction,have high safty function.

Product parameters

|

Name |

technical |

capacity |

External dimension (L*W*H) (mm) |

suggested power (KW) |

|

QHJ-2 |

Material is sus304 stainless steel; SEW reducer, diameter of the rubber roller: ¢295, diameter of roller with teeth: ¢298; the speed is changeable by frequency |

≤2(T/H) |

970*925*1225 |

3 |

|

QHJ-5 |

3~5(T/H) |

1320*1106*1300 |

4 |

|

|

QHJ-10 |

6~10(T/H) |

2150*1375*1710 |

7.5 |

|

|

QHJ-15 |

11~15(T/H) |

2450*1375*1710 |

11 |

|

|

QHJ-20 |

16~20(T/H) |

2750*1375*1710 |

15 |