Fruit pulping machine, also known as fruit puree machine, is a device used to make fruit mash or fruit puree. It is widely used in the food processing industry, especially in fields such as juice, jam, wine, and seasoning.

The main working principle of a fruit masher is to cut, peel, and pit fruits before crushing, stirring, and filtering them through high-speed rotating blades and screens, making the fruit flesh into a delicate fruit mash. Specifically, the workflow of the fruit masher includes the following steps:

Feeding and cutting: Put the pre processed fruits into the hopper of the fruit masher and continuously feed them through the feeding device. At the same time, the blade rotates at high speed while cutting the fruit, breaking it down into smaller particles.

Grinding: Fruit particles enter the machine and are further crushed, stirred, and ground through the friction and impact of high-speed rotating blades and screens, resulting in the flesh of the fruit becoming small particles or mashes.

Filtration: After the fruit mash is ground, it is filtered through a sieve to remove impurities such as solid particles, skin residue, and seeds from the juice, while retaining the delicate fruit mash.

Collection and packaging: After being filtered, the fruit paste flows out through a pipeline or discharge port and enters the collection container. Then package as needed for storage and sales.

The characteristics of the fruit masher include:

Efficient and fast: The fruit mashing machine adopts high-speed rotating blades and screens, which can quickly crush fruits into fruit mashes and improve production efficiency.

Simple operation: Fruit mashing machines usually have a simple operating interface and control system, which is easy to operate and control operating parameters, reducing the threshold for use.

Good regulation performance: The fruit masher can be adjusted according to the characteristics and needs of different fruits, such as adjusting the thickness of the sieve, adjusting the speed of the blades, etc.

Durable and sturdy structure: Fruit mashing machines are usually made of corrosion-resistant materials such as stainless steel, with strong structural stability and durability, making them easy to clean and maintain.

By using a fruit mashing machine to make fruit mash, the aroma, taste, and nutrition of the fruit can be fully preserved, making the fruit mash more delicate and taste better. The fruit mashing machine plays an important role in the preparation process of fruit mash and is also one of the indispensable equipment in the food processing industry.

Usage: This machine can be used to pulp on the following fruits;

Stone fruits after the stonehas been removed, such as mango, peach, apricot, date;Also used for the baccas(Chinese goose beery and strawberry);

Kernel fruits after been cookedand softened(such as apple,pear,pumpkin)

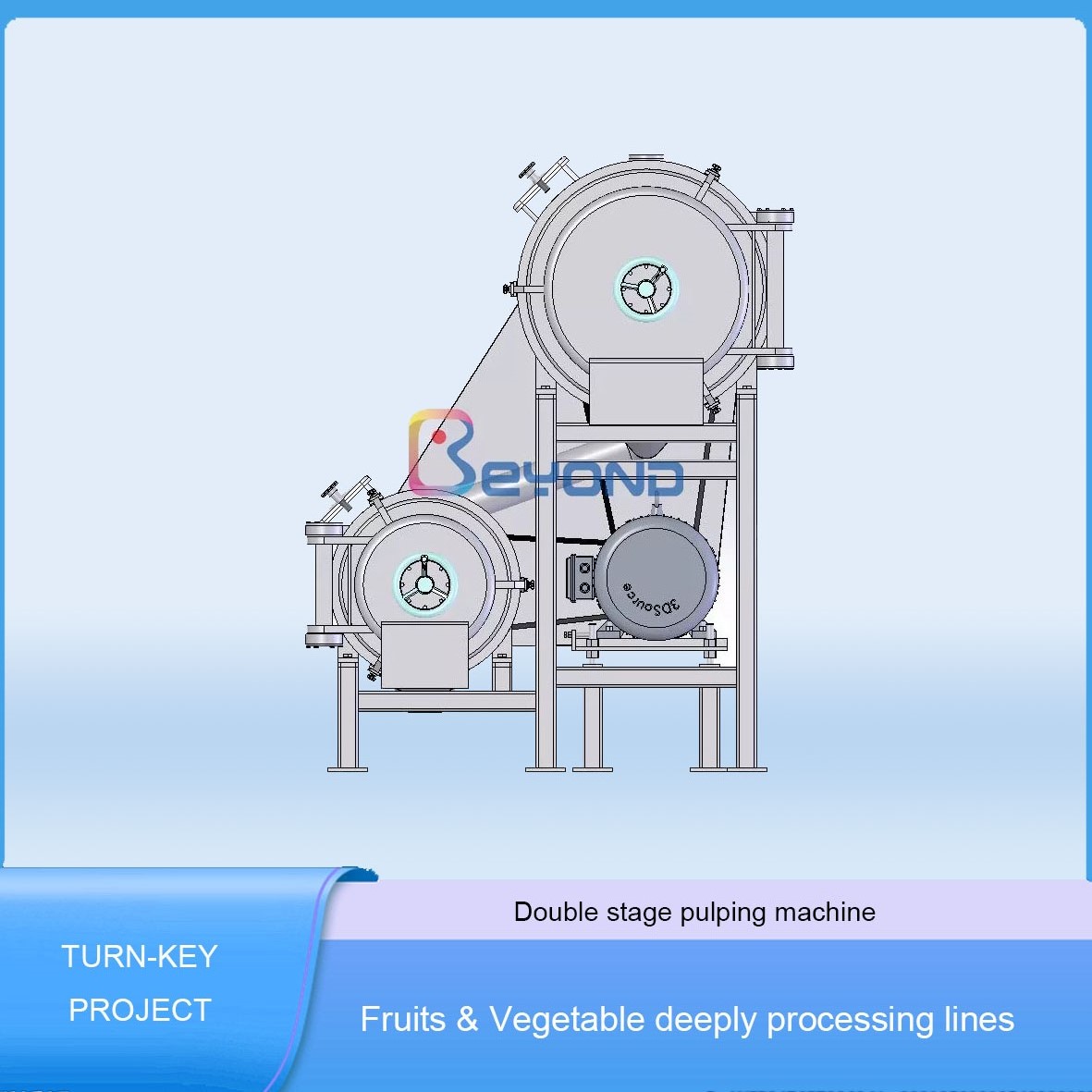

The double stage pulping machine adopts two stages pulping toenhance the quality of the fruit pulp, to make it even thinner and separate the dreg with fruit in further.

fruit pulp and the dregseparate automatically;

can be mounted in a processing line, and also can perform the production by own.

All the material where contact with the product is made of high quality stainless steel which are in standard of food requirements.

Easy to clean and disassemble and assemble.

|

Model

|

Description |

External dimension(mm) L*W*H |

Suggested capacity |

Suggested power |

|

capacity and power varies as to different fruits |

||||

|

SDJ-2 |

All made of sus304 stainless steel, rotating 960RPM-1350RPM |

1170*950*1250 |

≤2(T/H) |

7.5 |

|

SDJ-5 |

1760*1350*1500 |

3~5(T/H) |

18.5 |

|

|

SDJ-10 |

1950*1550*1880 |

6~10(T/H) |

30 |

|

|

SDJ-15 |

2150*1550*1880 |

11~15(T/H) |

37 |

|

Scope of application:

Mainly used in berries, tomatoes and other raw materials, so that pulp, fruit juice and other parts of its separation, easy to juice concentration and other follow-up processes.

Suitable for the separation of pulp and slag from the pulp and fruits of various types of berries and ribs after crushing and pre-cooking. One for rough pulping and two for fine pulping.

Suitable for places where the relative humidity is not greater than 70%, the temperature is not higher than 40℃, the ventilation is dry, and the shelter is sheltered. The pulping of softened hawthorns, dates and other fruits is separated.

Equipment advantages:

(1)The frame adopts a whole frame welding structure, with good overall rigidity and low vibration.the frame adopts the whole frame overall welding structure, the overall structure strength is high, the rigidity is good, the vibration is small;

(2)Before leaving the factory, the rotating shafts have passed the dynamic balance test, and the product performance match the requirements.

(3)The movable door of the stone outlet adopts a unique hinge mechanism design, one person can easily open the movable door horizontally, making the cleaning and replacement of the screen more convenient.

(4)All made by stainless steel, match the food sanitary standard.

(5)Design with auto cleaning interface, inner with multi-angle spray ball, high standard of auto cleaning.

(6)The machine can be designed on a processing line, auto production with low labor intensity.

(7)Fully enclosed structure except the feeding and discharging, good safety protection performance.

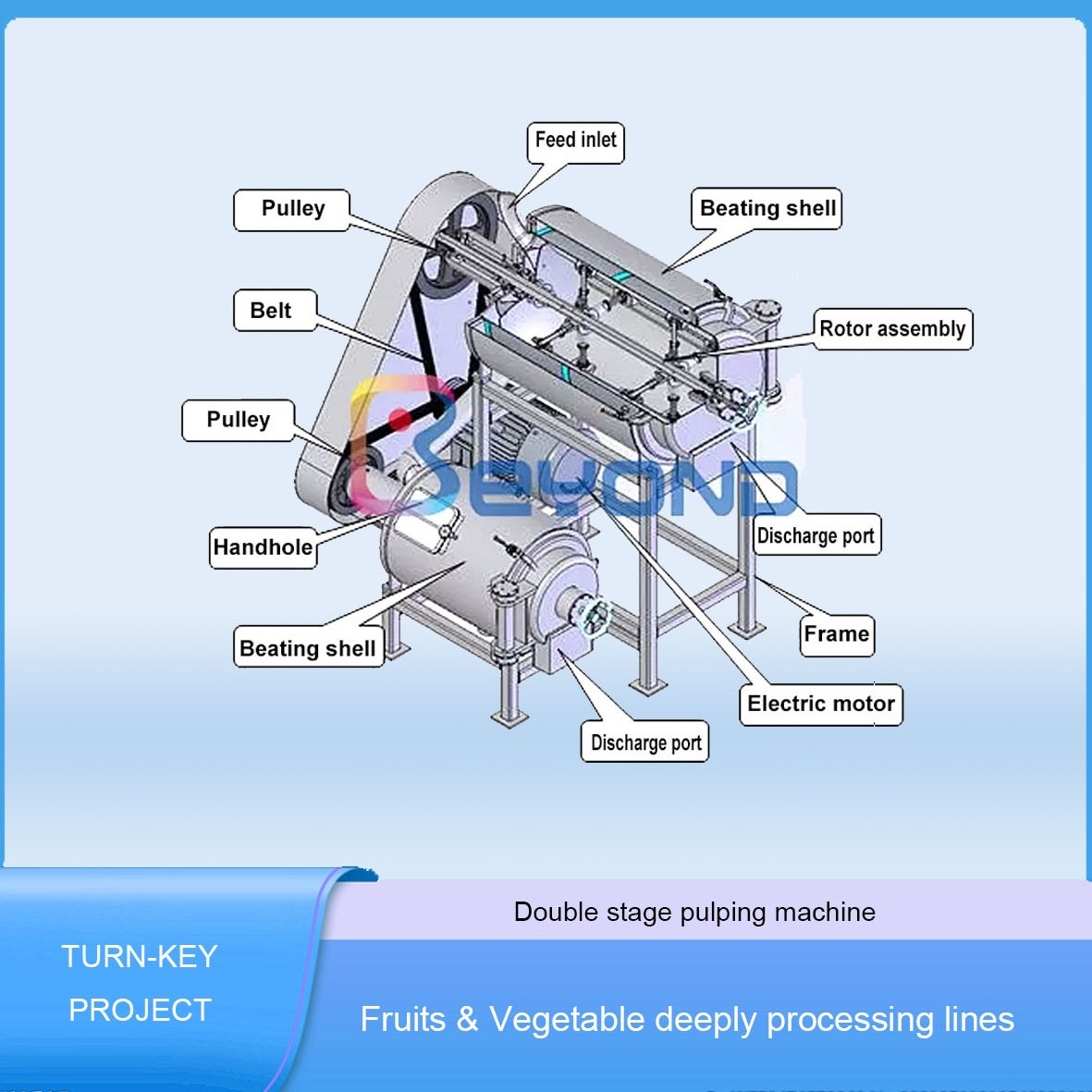

Equipment structure:

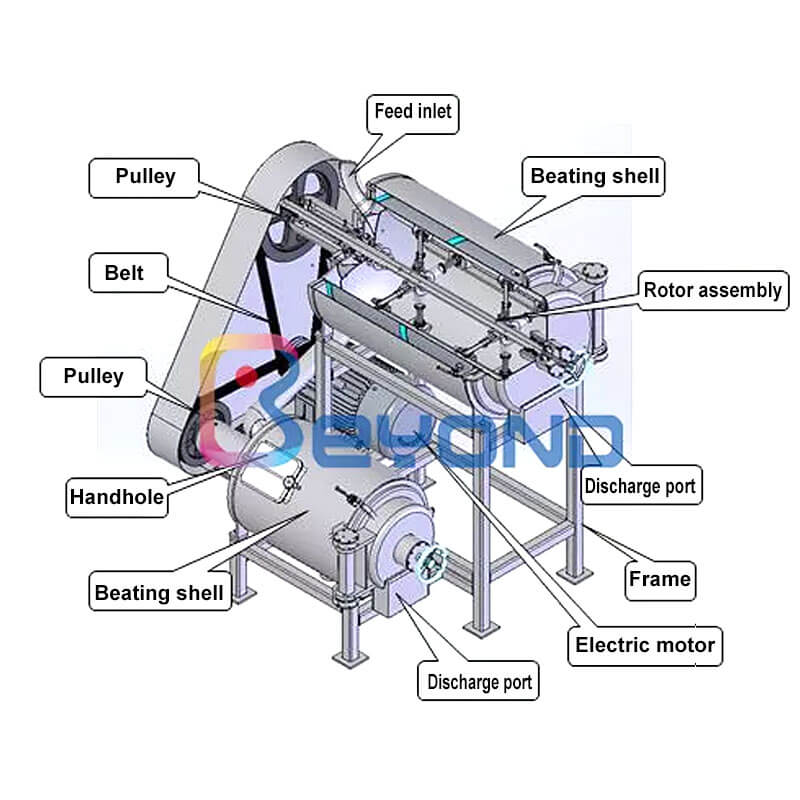

Overall structure :

Internal structure diagram:

As shown above, Mainly by the housing, rack, motor, rotor assembly, belt, bearings, pipes, pulping rotors and so on.

Features of the machine:

The device completes the separation of pulp from the bad ingredients that affect the quality of the product, and the content of polyphenols in the treated fruit is greatly reduced, thus reducing the temperature required for purification enzyme, reducing energy consumption, reducing the chance of enzyme browning, and improving the color value and stability of the product.

Different materials can choose different pulping methods, different screen aperture, you can get the ideal juice out of the pulp.

Compared with the traditional system can enhance the brightness and yellow tone to reduce the red tone, so that the red peel of the fruit pulp in the quality of better, the activity of oxidase greatly reduced so that the natural color of the fruit can be maintained.

Compared with heat extraction, the temperature required for enzyme tumbulation is low. Better removal of dark spots and effective reduction of natural brown spots, effective reduction of pesticide residues in the follow-up process process, thereby reducing the product in the equipment stay time.

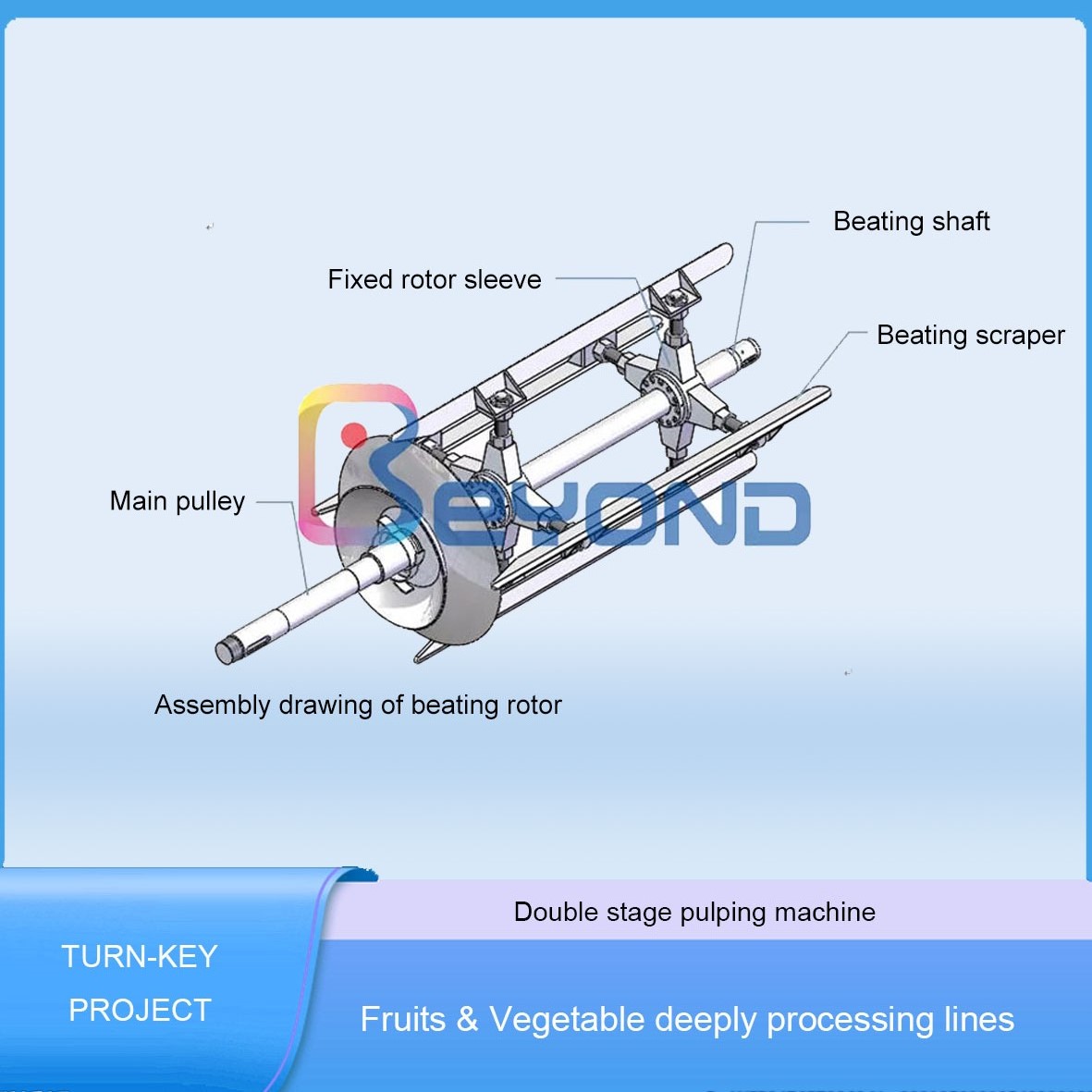

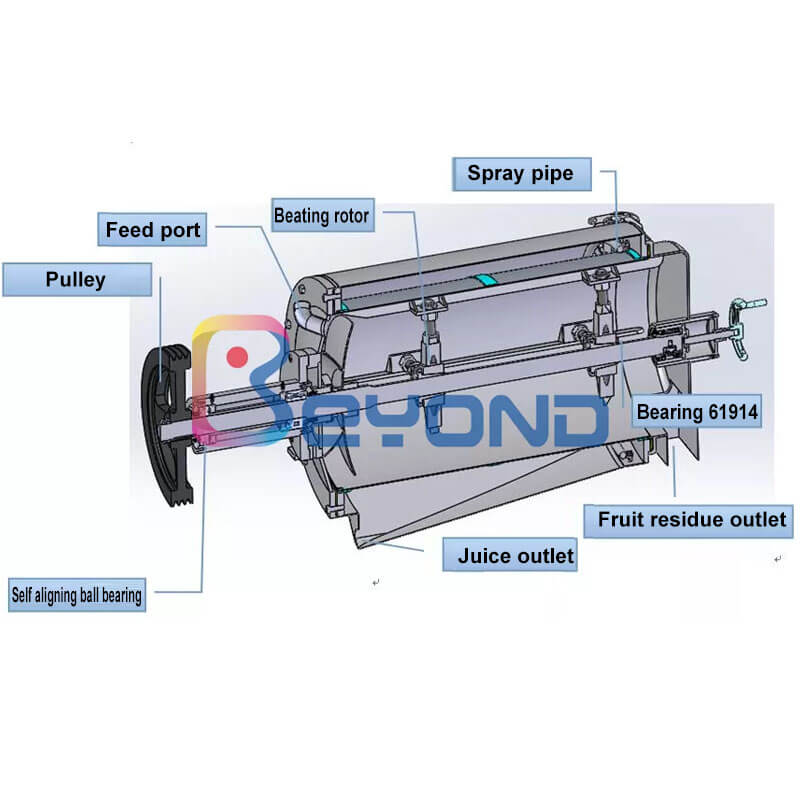

Working principle:

When working, broken or cooked soft fruit enters the screen through the feed port, and as the rotor rotates, the fruit frictions with the screen along the S-shaped path by the rotor's scraper pressed against the inner wall of the screen due to centrifugal forces. The berry attached to the nucleus is gradually scraped down, discharged through the mesh of the screen, and eventually accumulated in the shell from a berry berry outlet into a second pulp screen into the second pulping outlet. Due to the force of gravity, the pulp moves towards the moving door and is discharged by the fruit slag outlet.

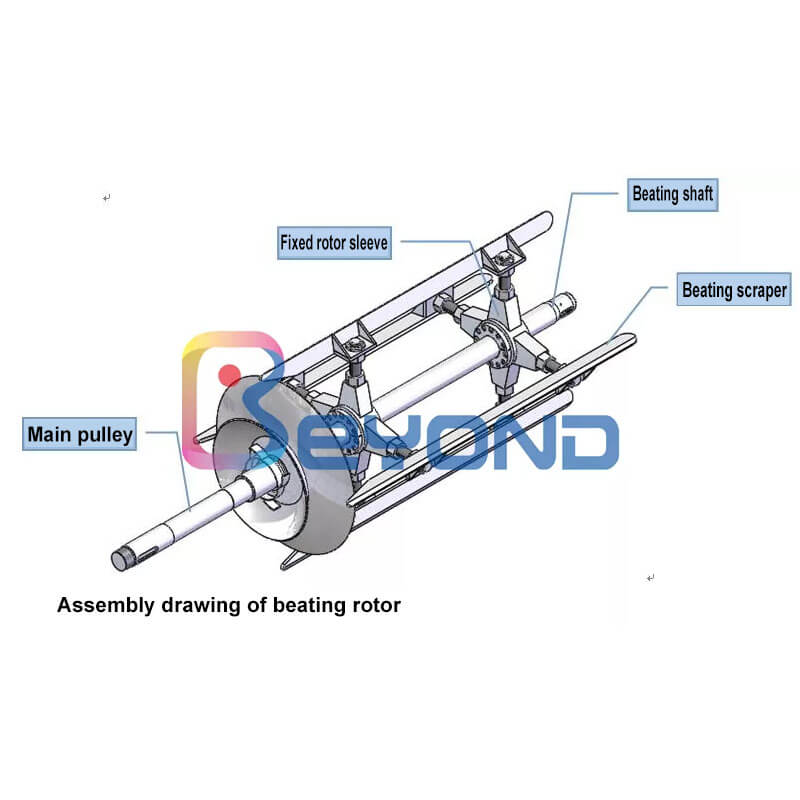

The ends of the rotor shaft are mounted on the main housing and the moving door respectively, and the scraper mounted on the rotor is tightened by stainless steel rotors and bolts, and the distance from the inner wall of the screen is adjusted by the number of gaskets.

In order to increase the dwell time of the pulp in the screen, so that its surface is fully frictioned, pulping more fully, so the scraper is designed to be angled with the screen axis, rather than parallel to the axis.

Power is provided by the motor and is transmitted to the rotor via the wheel and V-belt. The moving door can be opened as needed and is generally used to remove the screen and clean the inside of the housing thoroughly and regularly.

Considering the smooth discharge of the pulp, the scraper design has a tilt with the shaft and a lead angle after installation.

The housings are set up to observe the interior without opening the active door.