I. Main functions

1. Raw material reception and pretreatment

• Receive fresh grapes delivered from the vineyard.

• Carry out preliminary screening to remove impurities and unqualified fruits.

• Classify according to variety and purpose.

2. Cleaning and disinfection

• Thoroughly clean the grapes to ensure that surface dirt and pesticide residues are removed.

• Disinfect when necessary to prevent microbial contamination.

3. Crushing and stem removal

• Use mechanical equipment to crush the grapes so that the juice flows out.

• Remove grape stems to reduce bitterness and unpleasant flavors.

4. Fermentation and brewing (for wine production)

• Put the crushed grape pulp into the fermentation tank and add yeast for fermentation.

• Control parameters such as temperature and time to ensure the smooth fermentation process.

• Regularly test indicators such as sugar and acidity and adjust fermentation conditions.

5. Pressing and filtration

•After fermentation, use a press to separate the skins and wine.

•After multi-stage filtration, remove suspended matter and impurities to make the wine clearer.

6. Blending and stabilization

•Blending (such as adding sugar, acid, alcohol, etc.) is carried out according to product requirements.

•Stabilization treatment is carried out to prevent precipitation and deterioration and extend the shelf life.

7. Filling and packaging

•Aseptic filling of finished products to ensure product quality.

•Use appropriate packaging materials (such as glass bottles, plastic bottles, cartons, etc.) and label them for easy transportation and sales.

8. Quality control and testing

•Set up online testing points in key processes to monitor product quality in real time.

•Perform sensory evaluation, physical and chemical index analysis and microbial testing on each batch of finished products to ensure that they meet quality standards.

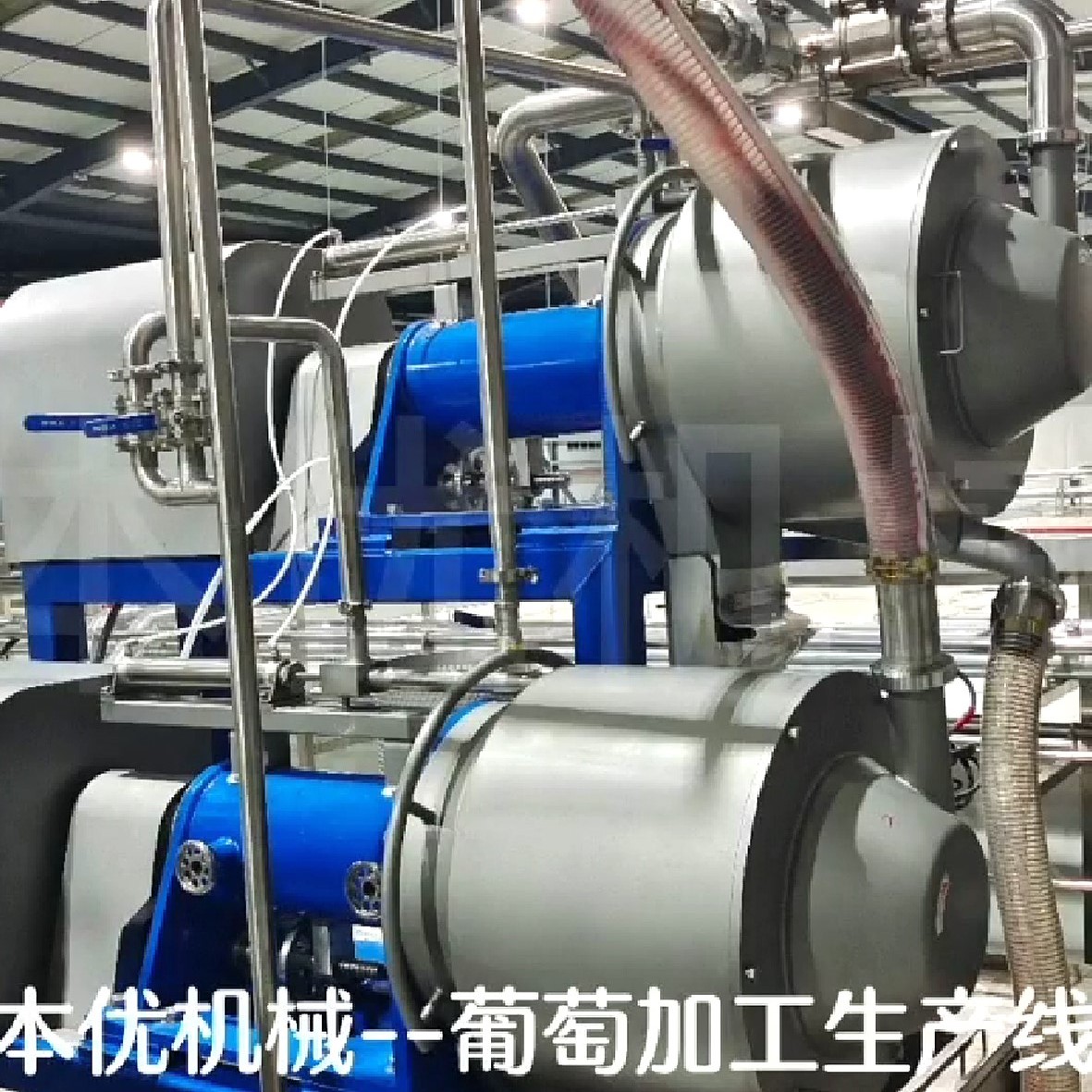

1. Advanced equipment

•Adopt modern production equipment, such as automated conveyor belts, crushers, fermentation tanks, presses, filters, etc.

•Introduce intelligent control systems to achieve precise operation and management.

Grape processing equipment and sorting line are modular, and there are a variety of equipment to choose from to meet different needs,

-Grape washing and drying channel

-Vibration screening device

-Sorting table of conveyor belt

-Stainless steel vibrating sorting table

-Ladder conveyor

-Grape stemming machine

-Roller crusher

2. Environmental protection technology

• Apply wastewater treatment system to reduce environmental pollution.• Use renewable energy such as solar energy and wind energy to reduce energy consumption and carbon emissions.

We can discuss in detail the raw materials and products of the grape juice production line from the following aspects:

1. Raw materials

•

Fresh grapes: This is the main raw material for producing grape juice. Choosing fresh, ripe, and pest free grapes is crucial to ensure the taste and nutritional value of the final product.

•

Water: Used for cleaning grapes and diluting concentrated grape juice.

•

Sugar: Adjust the sweetness of grape juice as needed.

•

Vitamin C: Sometimes added to enhance the nutritional value of grape juice.

•

Preservatives: Optional, used to extend the shelf life of products.

2. Product

•

Freshly squeezed grape juice: directly extracted from fresh grapes, retaining the most nutrients.

•

Concentrated grape juice: made by evaporating some of the water, convenient for transportation and storage.

•

Resveraging grape juice: Made from concentrated grape juice and water, it is convenient for large-scale production and distribution.

•

NFC (Not From Concentrate) Grape Juice: Non concentrated reduced grape juice, extracted directly from fresh grapes without concentration treatment, with a taste closer to freshly squeezed grape juice.

•

Functional grape juice: Specific nutrients such as vitamins, minerals, etc. can be added to meet the needs of different consumers.

Some advantages of grape juice processing line:

1. The equipment has simple operation, powerful machine performance and low energy consumption.

2. It is a convenient device, which can identify unqualified grapes, immature grapes, bad grapes and hidden impurities in grapes.

3. Remove the residual gravel, sand, stems and raw grape grains in the grape cluster.

Technological process of grape juice processing line:

First, the grape grains are sent to the vibrating screen to remove the impurities hidden in unqualified grapes, immature grapes, bad grapes and grape grains. Then, the grape seeds are evenly sent to the stemming machine through the elevator to completely remove the stems, which will not cause damage to the grape fruit. Then, the grape granules are peeled and seeded, and the grape pulp is beaten, sterilized and filled.

We manufacture all the equipment needed for grape juice production; From raw grape unloading system to grape juice extraction system, from grape juice ultrafiltration system to grape juice evaporator system, grape juice pasteurizer, grape juice clarification system, grape juice degumming tank and grape juice processing tank to grape juice storage tank.

Customizing a grape juice production line

Customizing a grape juice production line requires comprehensive consideration of multiple factors, including raw material selection, process flow, equipment configuration, and quality control. Here is a detailed customization plan:

1. Raw materials

•

Fresh grapes: Choose fresh, ripe, and pest free grapes to ensure the taste and nutritional value of the final product.

•

Water: Used for cleaning grapes and diluting concentrated grape juice.

•

Sugar: Adjust the sweetness of grape juice as needed.

•

Vitamin C: Sometimes added to enhance the nutritional value of grape juice.

•

Preservatives: Optional, used to extend the shelf life of products.

2. Product

•

Freshly squeezed grape juice: directly extracted from fresh grapes, retaining the most nutrients.

•

Concentrated grape juice: made by evaporating some of the water, convenient for transportation and storage.

•

Resveraging grape juice: Made from concentrated grape juice and water, it is convenient for large-scale production and distribution.

•

NFC (Not From Concentrate) Grape Juice: Non concentrated reduced grape juice, extracted directly from fresh grapes without concentration treatment, with a taste closer to freshly squeezed grape juice.

3. Key equipment

•

Cleaning equipment: used for cleaning grapes, removing soil and impurities from the surface.

•

Crusher: Crushes grapes into small pieces for easy juice extraction.

•

Juicer: Efficient for extracting grape juice, commonly used are screw juicers and centrifugal juicers.

•

Filter: Used to remove pulp and fiber from juice, making the juice clearer.

•

Clarification equipment: further remove suspended solids in the juice to improve transparency.

•

Sterilization equipment: using UHT (ultra-high temperature instantaneous sterilization) or pasteurization technology to ensure the safety of juice.

•

Filling equipment: Automated filling lines ensure the sealing and hygiene standards of juice.

•

Packaging equipment: used for packaging filled fruit juice, commonly including PET bottles, glass bottles, and paper box packaging.

•

Storage equipment: used to store finished grape juice, maintaining its freshness and quality.

4. Process flow

one

Raw material reception and inspection: Receive fresh grapes and conduct quality inspection.

two

Cleaning: Use cleaning equipment to thoroughly clean the grapes.

three

Crushing: Use a crusher to break grapes into small pieces.

four

Juice extraction: Use a juicer to extract grape juice.

five

Filtering: Use a filter to remove pulp and fiber.

six

Clarification: Use clarification equipment to further remove suspended solids and improve transparency.

seven

Sterilization: UHT or pasteurization technology is used for sterilization treatment.

eight

Cooling: Quickly cool after sterilization to maintain the freshness of the juice.

nine

Filling: Fill the juice into a container.

ten

Sealing: Seal the filled juice.

eleven

Packaging: Pack the sealed juice.

twelve

Inspection and warehousing: Conduct quality inspection on finished products, and store them in the warehouse after passing the inspection.

5. Cost estimation

•

Equipment investment: Depending on the scale and degree of automation of the production line, equipment investment may range from several hundred thousand to several million RMB.

•

Operating costs: including raw materials, energy, labor, and maintenance expenses.

•

Time cycle: From initial consultation to production line launch, it usually takes 6 months to 1 year.

6. Key precautions

•

Hygiene standards: Ensure that the entire production process meets hygiene standards and avoids contamination.

•

Quality control: Conduct regular quality inspections to ensure product consistency and stability.

•

Environmental protection: Reasonably handle the wastewater and waste generated during the production process to reduce the impact on the environment.

7. Continuous support and optimization

•

Technical support: Provide regular technical support and maintenance services.

•

Performance optimization: Continuously optimize the performance of the production line based on actual operating conditions to improve production efficiency.

•

Troubleshooting: Develop a rapid troubleshooting plan to ensure stable operation of the production line.

•

Supplier relationship: Maintain a good relationship with equipment suppliers in order to obtain continuous support and upgrades.

Conclusion

Customizing a grape juice production line is a systematic project that requires comprehensive consideration of market demand, production processes, equipment selection, and operating costs.