The fruit stone washer is a device specifically designed for cleaning fruit pits. It adopts advanced washing technology, which can efficiently remove surface attachments of fruits and ensure the cleanliness of the inner core of fruits. The working principle is as follows:

Load fruit kernels: Place the fruit kernels that need to be cleaned into the feed port of the washing machine.

Fruit Kernel Sorting: The machine will sort the fruits based on the set parameters, eliminating any fruit kernels that do not meet the requirements.

Pre treatment: Before starting the formal cleaning, the washing machine pre-treates the fruit kernels. This includes removing surface impurities, sand, and residual fruit pulp.

Cleaning: The cleaning machine thoroughly cleans the fruit kernels by spraying water or soaking them. At the same time, appropriate cleaning agents can be used to enhance the cleaning effect.

Rinse: After cleaning, thoroughly rinse the fruit kernels to ensure that there is no residual cleaning agent.

Screening: The cleaned fruit kernels will go through a screening device to remove residual impurities and foreign objects.

Discharging: Finally, the cleaned fruit kernels will be discharged from the discharge port of the washing machine, which can be further processed or packaged.

The fruit pit cleaning machine has important application value in the fruit processing industry. It can improve the hygiene quality of fruit kernels, reduce the risk of spread of pathogens and pollutants, and ensure the hygiene and safety of fruit processing. At the same time, the fruit pit cleaning machine can also improve the appearance quality of fruit pits and increase the added value of the product. It is widely used in fruit planting bases, fruit and vegetable processing enterprises, food processing industries, and other fields, providing people with a better food experience.

Main use:

The core remover is mainly used to separate the core and pulp of the fruit with hard cores.

Scope of application: fruits with hard cores, such as peaches, apricots, etc.

Direction for use

1.The external frame is totally welded, so it has good rigidity with little shake;

2.Stoner discharge port is mounted with a gate connected by gemel, so it is simple to disassemble and assemble and also clean;

3.All made of sus304 stainless steel;

4.The machine can be auto cleaned by spraying water from multi points;

5.The machine can be mounted in a processing line to working together with the other equipments.

Description of application effect

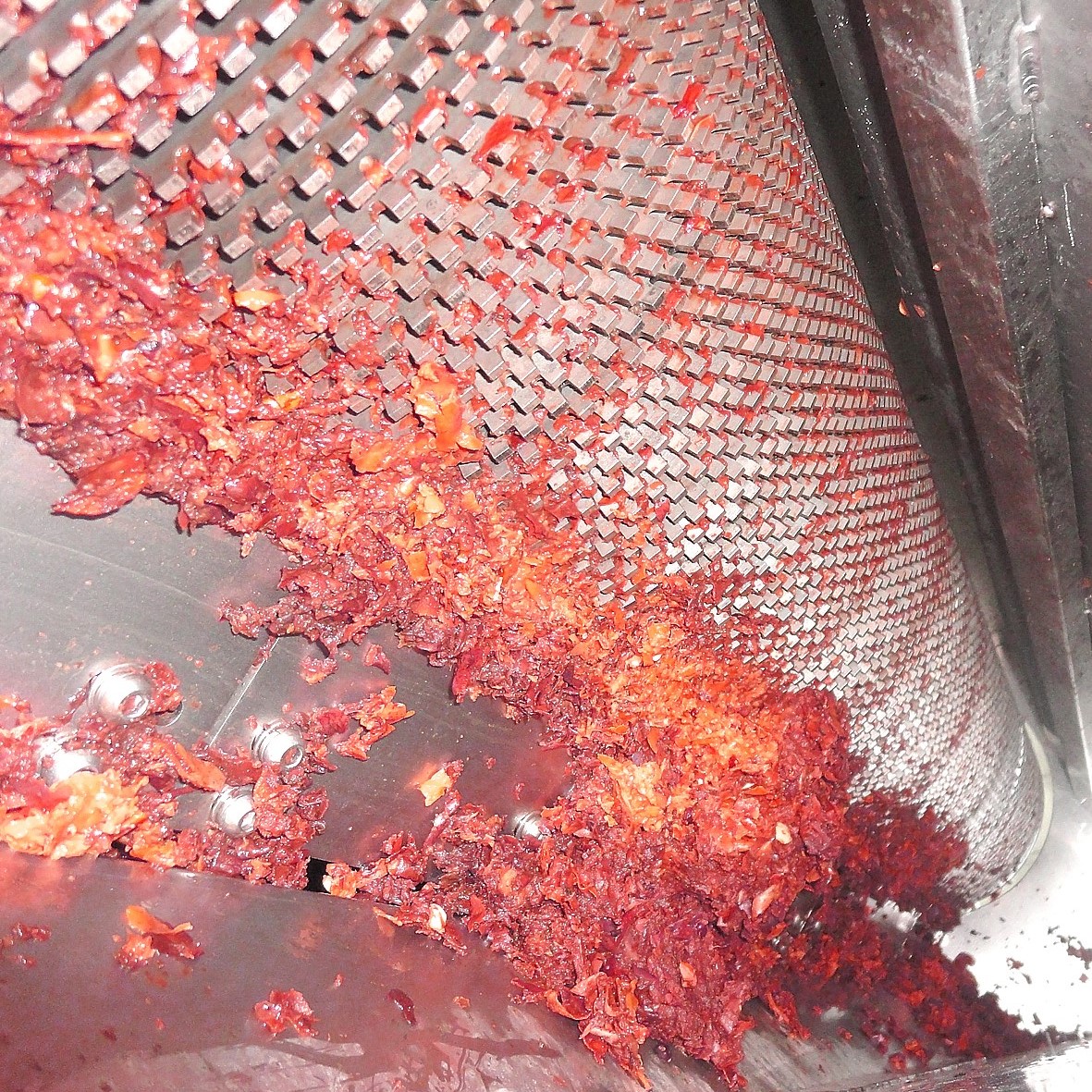

After the core enters the inlet of the washing machine through the outlet of the destoner, it is sent into the cavity throughthe screw propeller, and is driven along the inner wall of the screen by the scraper at the top of the rotor. Under the action,the flesh on the core gradually goes out through the sieve mesh, and the core is discharged from the bottom end in a spiral trajectory at a certain angle.

Product Description

Separate the fruit flesh and the stone effectively;higher effectively and easy operation;the gap between the rollers can be regulated to get a best process efficient; the rollers and the scraper can be replaced considering the status of the machine, and it is easy to do the replacement.

Technical parameter

| Model | Description |

External dimension (L*W*H)(mm) |

Suggested Capacity | Suggested Power |

|

capacity and power varies as to different fruits |

||||

| XHJ-2 | Material is sus304 stainless steel, rotation speed is 400-500RPM | 1500*500*1375 | ≤2(T/H) | 4 |

| XHJ-5 | 1500*650*1310 | 3~5(T/H) | 7.5 | |

| XHJ-10 | 1800*910*2050 | 6~10(T/H) | 18.5 | |

| XHJ-15 | 2100*1110*2050 | 11~15(T/H) | 22 | |

| XHJ-20 | 2300*1210*2050 | 16~20(T/H) | 30 | |

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

Related machinery of fruit processing line

Fruit storage silo-- Washing, sorting machine-- Grading/classifier machine

Squeeze extractor--Juice refiner-separator-evaporator-- Juice concentrate product

Fruit flesh/pulp collector-sterilizer--filling machine-fruit flesh

Essential oil refiner-fruit oil

Fruit residues collector-animal feed

Soaking extraction, pre-cooking, pulping, quick freeze, stemmer, ultra-filtration, decolor, destoner, crusher, stone washer, brusher washer, pine apple extractor, refiner, enzymolysis, filtration, CIP cleaning system.