The milk powder production line is a sophisticated system designed to convert fresh milk into powdered form while retaining its nutritional value and quality. This process involves several stages, including raw milk acceptance, standardization, preheating, homogenization, sterilization, concentration, and drying.The resulting milk powder is lightweight, has a long shelf life, and is easy to transport and store.

Key Components of a Milk Powder Production Line

Raw Milk Acceptance System

The process begins with the acceptance of raw milk, which is then stored in tanks. This system ensures that the milk is of high quality and free from contaminants.

Standardization and Preheating

Raw milk is standardized to achieve the desired fat and protein content. It is then preheated to prepare it for further processing.

Homogenization and Sterilization

Homogenization ensures that the fat globules in the milk are evenly distributed, while sterilization eliminates harmful bacteria and extends the shelf life of the product.

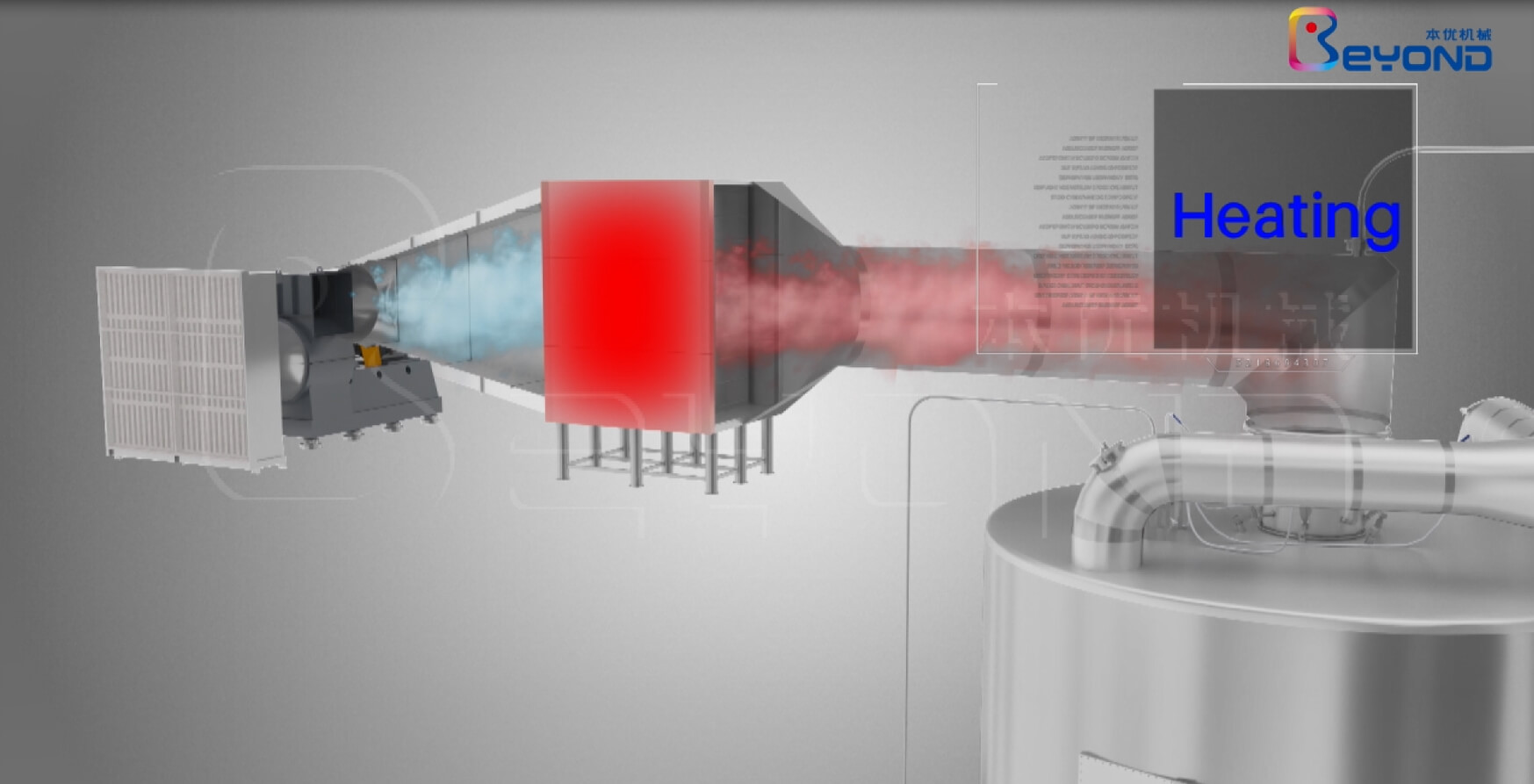

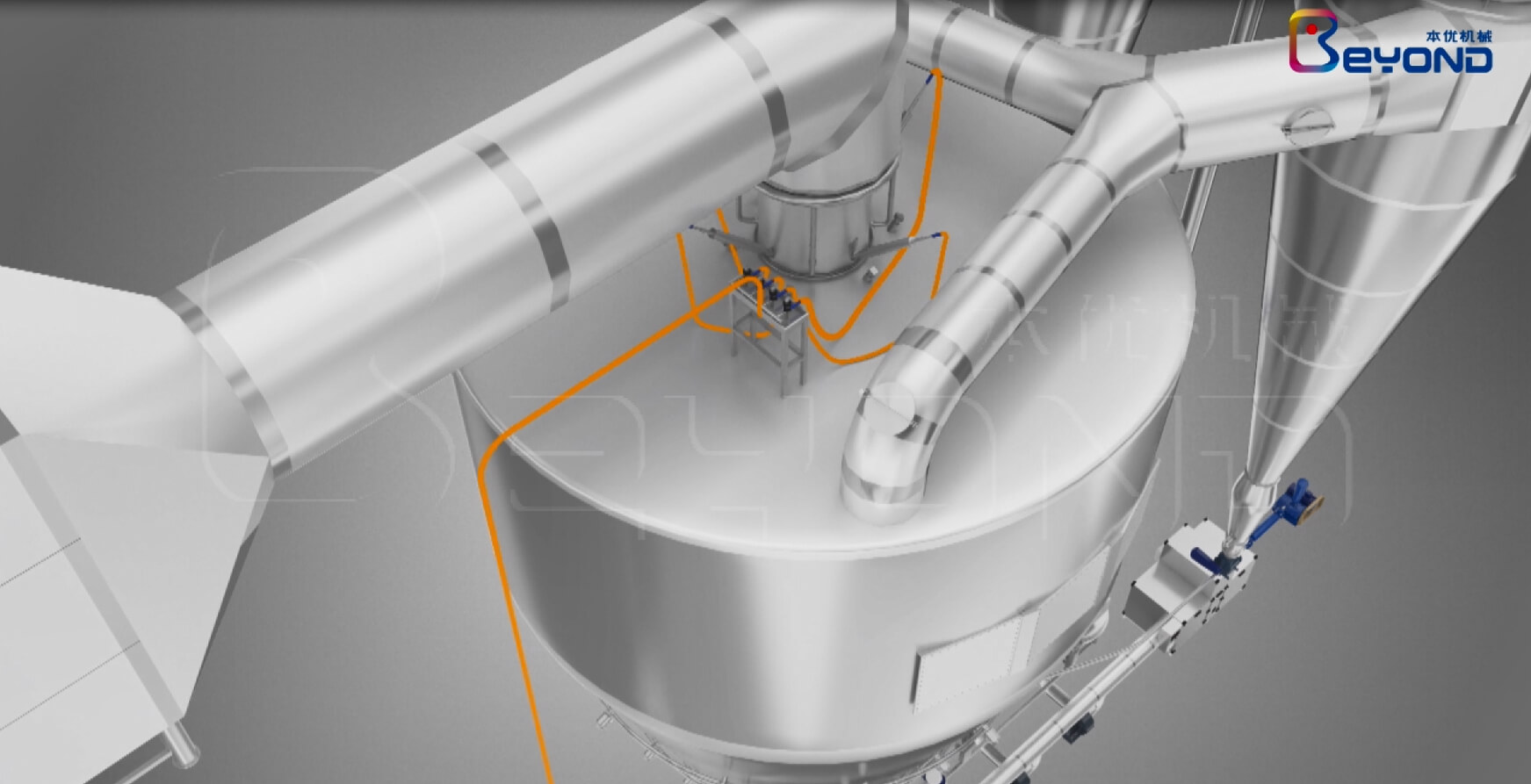

Concentration and Drying

The milk is concentrated using a vacuum evaporator, which removes excess water while preserving the milk's nutritional value. The concentrated milk is then dried using advanced spray drying equipment, resulting in fine milk powder.

Packaging and Quality Control

The final milk powder product is packaged in various formats, such as tinplate cans, plastic aluminum foil composite bags, and carton boxes.The entire production process is monitored by a CIP cleaning system and strict quality control measures to ensure the final product meets high standards.

Milk Powder Plant Project Cost

Setting up a milk powder production plant involves significant capital investment. The cost includes land and site development, civil works, machinery and equipment, packaging materials, and working capital.For example, a typical dairy processing plant project may require an investment of around 255.15 lakhs for site development, civil works, plant and machinery, vehicles, and miscellaneous fixed assets.

Operating Costs and Financial Considerations

Operating a milk powder plant involves ongoing expenses such as raw materials, labor, utilities, packaging, and maintenance.The cost of raw milk, which is a major input, can vary depending on market conditions.Other variable costs include packaging materials, chemicals, and transportation.

Conclusion

A milk powder production line is a complex but essential system for converting fresh milk into a versatile and long-lasting product. The initial investment and operating costs are significant, but the demand for milk powder in various applications, such as food manufacturing and animal feed, makes it a potentially profitable venture.With the right planning and management, a milk powder manufacturing plant can be a successful addition to the dairy processing industry.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of Milk powder processing plant equipment.Please contact us now, and our professional technical engineers will customize the equipment plan for Milk powder plant and provide a quotation.Please contact us now to obtain the latest equipment plan and quotation.