Brief description of flavored milk production line

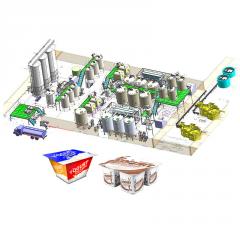

The flavored milk production line is an automated system specially designed for producing various flavored milks, covering the entire process from raw material processing to finished product packaging. The following is a brief description of the key components and main process flows of the production line:

1. Production line composition

•Raw material reception and storage:

•Receive fresh raw milk and other raw materials.

•Use cold storage and storage tanks to store raw materials and ensure that they are stored at a suitable temperature.

•Pretreatment system:

•Filter: Remove impurities from milk.

•Standardization equipment: Adjust the fat content and other component ratios in milk to meet product standards.

•Heating and cooling system:

•UHT sterilization equipment: Use ultra-high temperature instantaneous sterilization (UHT) technology to ensure thorough sterilization.

•Plate heat exchanger: Used to preheat, heat and cool milk to improve energy efficiency.

•Ingredient system:

•Mixing tank: Mix milk and flavor substances to ensure uniform distribution.

•Measuring pump: Accurately control the amount of flavor substances added.

•Homogenizer: Refine the fat particles in milk to improve taste and stability.

• Aseptic packaging system:

• Aseptic filling machine: ensure that the product is not contaminated throughout the shelf life.

• Packaging material handling: automatically handle and convey packaging materials, and perform sealing and labeling.

• Automatic control system: integrate PLC or other advanced control systems to achieve automated operation and real-time monitoring.

2. Production process

1. Raw material preparation: receive and process raw milk and other raw materials.

2. Preheating and UHT sterilization: heat the milk to above 135°C and keep it for a few seconds, and cool it quickly.

3. Ingredients and mixing: mix the cooled milk with flavor substances to ensure uniformity.

4. Homogenization: refine the fat particles through the homogenizer.

5. Aseptic packaging: immediately perform aseptic packaging to ensure product quality.

6. Finished product inspection and warehousing: warehousing or shipment after passing the quality inspection.

3. Key technologies and parameters

• Heating temperature: 135°C to 140°C.

• Heating time: 2 to 5 seconds.

• Cooling temperature: around 4°C.

• Homogenization pressure: 20 to 30 MPa.

• Flavoring agent addition amount: precisely controlled by metering pump.

To ensure that the flavored milk production line can meet specific production needs and quality standards, the customization process needs to be comprehensively considered from planning to implementation. The following are the detailed steps of the customization process:

1. Requirement analysis

• Communicate with customers: understand their specific needs such as production goals, product types, and production capacity requirements.

On site investigation: Conduct on-site visits to existing facilities, evaluate spatial layout, infrastructure conditions, etc.

Market research: Analyze market demand and competition to ensure that production line design conforms to market trends.

2. Scheme design

Process design: Based on customer needs, design a reasonable production process flow, covering raw material processing, sterilization, batching, homogenization, packaging and other links.

Equipment selection: Choose suitable production equipment, such as UHT sterilization equipment, mixing tanks, homogenizers, sterile filling machines, etc., and consider factors such as equipment brand, performance, and maintenance costs.

• Automation control system design: Integrating PLC or other advanced control systems to achieve automated operations and real-time monitoring, improving production efficiency and product quality.

Environmental and safety design: Ensure that the production line meets environmental and safety standards, equipped with necessary waste gas treatment, wastewater treatment, and safety protection equipment.

3. Determination of technical parameters

Capacity planning: Determine the daily or hourly production capacity of the production line based on customer demand.

• Key parameter settings:

Heating temperature (135 ° C to 140 ° C)

Heating time (2 to 5 seconds)

• Cooling temperature (around 4 ° C)

Homogenization pressure (20 to 30 MPa)

• Flavor substance addition amount (precisely controlled by metering pump)

4. Scheme review and optimization

Internal review: The project team reviews the design proposal to ensure its rationality and feasibility.

Customer confirmation: Submit the design proposal to the customer for review, and make adjustments and optimizations based on customer feedback.

Expert consultation: If necessary, invite industry experts to evaluate the plan and provide professional advice.

5. Equipment procurement and installation

Equipment procurement: Purchase the required production equipment and auxiliary equipment according to the design plan.

Equipment transportation and installation: Arrange the transportation of equipment to the customer's site for installation and debugging to ensure the normal operation of the equipment.

Installation of pipelines and electrical systems: laying pipelines and electrical circuits, connecting various equipment, and conducting debugging.

6. Debugging and trial operation

Single machine debugging: Conduct separate debugging for each device to ensure its proper functionality.

Linkage debugging: Perform linkage debugging on the entire production line to test the collaborative work between various devices.

• Trial operation: Conduct small-scale trial production, inspect the stability of the production line and product quality, and promptly identify and solve problems.

7. Training and Delivery

• Operation training: Provide training for operators and technicians to ensure that they are proficient in operating and maintaining equipment.

• Document delivery: Provide complete equipment user manuals, maintenance manuals, and related technical documents.

Formal delivery: After the customer's acceptance is qualified, the production line is officially delivered and enters the after-sales service stage.

8. After sales service and support

Regular inspection: Regularly dispatch technical personnel to inspect the production line to ensure its long-term stable operation.

• Fault repair: Provide quick response fault repair services to reduce downtime.

• Technical support: Provide remote technical support to help customers solve technical problems encountered during the production process.

|

Equipment list DAIRY PRODUCTION plant (pasteurized milk\yogurt\cheese\cream\butter) |

||

| NO. | NAME | MAIN TECHNOLOGY PARAMETER |

| 1 | MILK RECEIVE\STORAGE\AND CREAM SEPARETOR UNIT | |

| 2 | Electron pound scale | maximum weighing 500KG |

| 3 | Milk weighing tank | made of SUS stainless steal,single layer,product feeded in through 40 mesh filter net,CIP cleaning ball |

| 4 | Milk acceptor | SUS304 stainless steel,single layer,CIP cleaning ball |

| 5 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 6 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 7 | Dish separator | auto residue discharge |

| 8 | Chiling tank | SUS304 stainless steel,alveolate jacket,attached with compressor |

| 9 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 10 | PREPARING UNIT | |

| 11 | Blending tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 12 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 13 | Mini set of plate-type heat exchanger | SUS304 stainless steel,two stages, |

| 14 | High speed emulsification tank | SUS304 stainless steel,heat insulated,bottom high speed emulsifier,digital readout thermometer,supporters with adjustable feet |

| 15 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 16 | Twin piping filter | SUS304 stainless steel,two pipe,Stainless Steal Filter Element 100 Mesh |

| 17 | Sterilizing,homogenizing unit | |

| 18 | UHT sterilizer | tub-type,sterilzing temperature 137 C,holding time 4S,full automatic control |

| 19 | High pressure homogenizer | 40MPa,(starting box included) |

| 20 | Temperature holding | SUS304,holding 300S |

| 21 | Distributing board | SUS304,3 holes |

| 22 | Cheese\butter processing unit | |

| 23 | Bufferying tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 24 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 25 | Cream seperator | |

| 26 | Bufferying container | SUS304,with cover |

| 27 | Milk pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 28 | Butter-churner | SUS304,stepless timing |

| 29 | Cheese vat | SUS304,with heating jacket and insising device |

| 30 | Pressor | SUS304,6 heads |

| 31 | Mould | SUS304,10L,with cover |

| 32 | Yogurt fermentation unit | |

| 33 | Fermentation tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 34 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 35 | Plate cooler | SUS304,single stage,milk discharge at 4degreeC |

| 36 | Rotary pump | SUS304 stainless steel,Hard Alloy Mechanical Seal,manual stepless shift |

| 37 | Filling unit | |

| 38 | Higher position tank | SUS304 stainless steel,heat insulated,top off- center votical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet |

| 39 | Pasteurized milk filling machine | |

| 40 | Yogurt filling machine | |

| 41 | CIP system | |

| 42 | Semi-auto CIP system | outer coat of SUS304 stainless steel material,inner shell of SUS316,single cleaning way,Concentrated acid/alcali tank adding system based on US technology, 100L×2 acid/alcali Concentrate tanks |

| 43 | CIP return pump | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| 44 | Installation part | project installation and commissioning |